Fundamentals

For a small to medium-sized business (SMB), the concept of a Supply Chain Strategy might initially seem like something reserved for large corporations with complex global operations. However, this couldn’t be further from the truth. Even the smallest coffee shop or the most niche online retailer operates within a supply chain, and having a deliberate strategy for managing it is crucial for survival and growth.

At its most fundamental level, an SMB Supply Chain Strategy is simply a plan that outlines how your business will source, produce, and deliver its products or services to customers. It’s about understanding the flow of goods and information, from the initial raw materials or components to the final product in the hands of your customer.

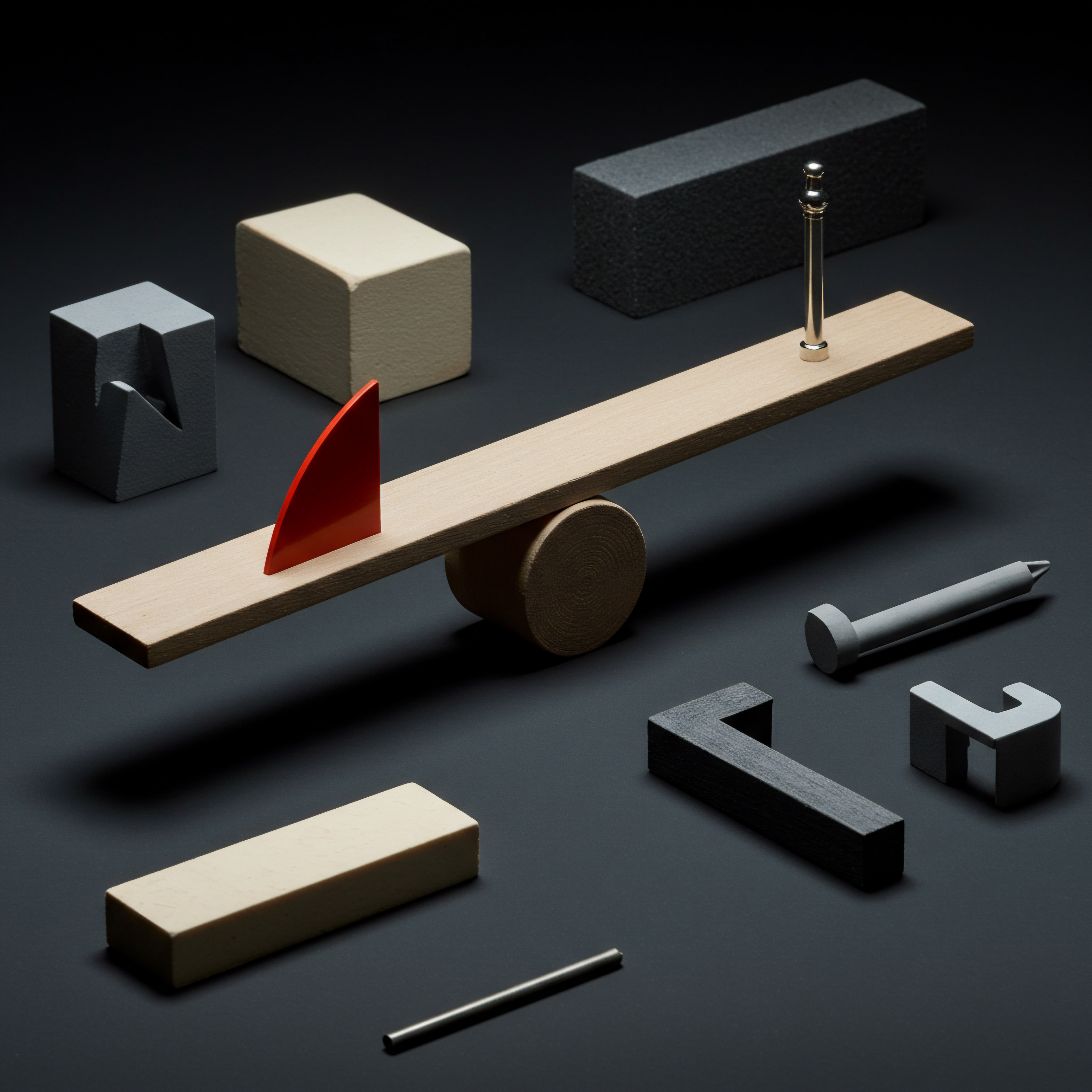

Think of it like the recipe for your business success. Just as a chef needs to carefully select ingredients, understand the cooking process, and ensure the dish reaches the diner in perfect condition, an SMB needs to manage each step of its supply chain. This includes:

- Sourcing ● Where do you get the materials or products you need to run your business? This could be raw materials, finished goods from suppliers, or even services you rely on.

- Production ● If you manufacture or assemble products, how do you do it efficiently and effectively? This includes your internal processes and any outsourcing of production.

- Inventory Management ● How much stock do you keep on hand? Too much inventory ties up capital, while too little can lead to lost sales and customer dissatisfaction.

- Logistics and Distribution ● How do you get your products to your customers? This involves transportation, warehousing, and order fulfillment.

- Customer Service ● How do you handle customer orders, returns, and inquiries related to your products or services? This is the final, and often most crucial, link in the supply chain.

For an SMB, a well-defined supply chain strategy isn’t about complex algorithms or global networks (at least not initially). It’s about making smart, practical decisions that optimize these core areas. It’s about efficiency, cost-effectiveness, and ultimately, customer satisfaction. A strong supply chain strategy can be a significant competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. for an SMB, allowing it to operate leaner, respond faster to market changes, and build stronger customer relationships.

A fundamental SMB supply chain Meaning ● SMB Supply Chain, in the context of Small and Medium-sized Businesses, represents the integrated network of organizations, people, activities, information, and resources involved in moving a product or service from supplier to customer. strategy is a practical plan for sourcing, producing, and delivering products or services efficiently and cost-effectively to satisfy customers.

Let’s consider a small bakery as an example. Their supply chain starts with sourcing ingredients like flour, sugar, and eggs. Their production is the baking process itself. Inventory management Meaning ● Inventory management, within the context of SMB operations, denotes the systematic approach to sourcing, storing, and selling inventory, both raw materials (if applicable) and finished goods. involves ensuring they have enough ingredients and baked goods to meet daily demand without excessive waste.

Logistics and distribution might be as simple as customers picking up orders in-store, or perhaps local delivery. Customer service Meaning ● Customer service, within the context of SMB growth, involves providing assistance and support to customers before, during, and after a purchase, a vital function for business survival. is crucial in taking orders, handling special requests, and resolving any issues. Even for this seemingly simple business, a conscious approach to each of these elements is part of their supply chain strategy.

Why is Supply Chain Strategy Important for SMBs?

Many SMB owners are deeply involved in the day-to-day operations and might wonder if formalizing a supply chain strategy is truly necessary. The answer is a resounding yes. Here’s why:

- Cost Reduction ● A well-thought-out strategy can identify inefficiencies and areas for cost savings throughout the supply chain. Negotiating better prices with suppliers, optimizing inventory levels, and streamlining logistics can all contribute to a healthier bottom line.

- Improved Efficiency ● By analyzing and optimizing each step of the supply chain, SMBs can eliminate bottlenecks, reduce waste, and improve overall operational efficiency. This translates to faster order fulfillment, quicker turnaround times, and happier customers.

- Enhanced Customer Satisfaction ● A reliable supply chain ensures that products are available when customers want them, delivered on time, and meet their quality expectations. This leads to increased customer loyalty and positive word-of-mouth referrals, which are invaluable for SMB growth.

- Increased Agility and Resilience ● SMBs with a flexible supply chain strategy are better equipped to adapt to changing market conditions, unexpected disruptions (like supply shortages or economic downturns), and evolving customer demands. This agility is crucial for long-term sustainability.

- Scalability for Growth ● As an SMB grows, its supply chain needs to scale accordingly. A proactive strategy anticipates future growth and lays the groundwork for a supply chain that can handle increased volume and complexity without breaking down.

Ignoring supply chain strategy is like driving a car without a map or a destination in mind. You might move forward, but you’re likely to waste fuel, take wrong turns, and end up further from your goal than you intended. For SMBs, especially in today’s competitive and dynamic market, a strategic approach to the supply chain is not just a nice-to-have, it’s a must-have for sustainable success.

Key Components of a Basic SMB Supply Chain Strategy

Even a basic SMB supply chain strategy should consider several key components. These don’t need to be overly complex, but they should be clearly defined and regularly reviewed.

Supplier Relationships

For most SMBs, suppliers are the backbone of their supply chain. Building strong, reliable relationships with key suppliers is paramount. This involves:

- Supplier Selection ● Choosing suppliers based not just on price, but also on quality, reliability, lead times, and their alignment with your business values.

- Communication and Collaboration ● Establishing clear communication channels and fostering a collaborative relationship where you can openly discuss needs, challenges, and opportunities.

- Contract Negotiation ● Negotiating favorable terms and contracts that protect your interests while ensuring fair and sustainable relationships with suppliers.

- Performance Monitoring ● Regularly evaluating supplier performance against agreed-upon metrics to identify areas for improvement and ensure consistent quality and delivery.

Inventory Management

Effective inventory management is a balancing act. SMBs need to have enough stock to meet customer demand but avoid holding excessive inventory that ties up capital and increases storage costs. Key considerations include:

- Demand Forecasting ● Predicting future demand based on historical data, market trends, and sales forecasts to inform inventory planning.

- Inventory Control Techniques ● Implementing methods like Just-in-Time (JIT) inventory (where possible for SMBs), Economic Order Quantity (EOQ), or ABC analysis to optimize inventory levels and minimize holding costs.

- Warehouse Management ● Organizing and managing warehouse space efficiently to facilitate easy storage, retrieval, and movement of inventory.

- Inventory Tracking ● Using systems (even simple spreadsheets initially) to track inventory levels, monitor stock movements, and identify potential stockouts or overstock situations.

Logistics and Distribution

Getting products from your business to your customers efficiently and cost-effectively is the essence of logistics and distribution. For SMBs, this might involve:

- Transportation Management ● Choosing the right transportation modes (e.g., local delivery, courier services, freight shipping) based on cost, speed, and reliability.

- Order Fulfillment Processes ● Establishing efficient processes for receiving, processing, picking, packing, and shipping customer orders.

- Delivery Options ● Offering customers convenient delivery options that meet their needs and expectations (e.g., standard shipping, expedited shipping, local pickup).

- Returns Management ● Developing a clear and customer-friendly process for handling product returns and exchanges.

Technology in Basic SMB Supply Chains

While advanced technology might seem out of reach for some SMBs, even basic technology can significantly improve supply chain management. Examples include:

- Spreadsheet Software ● Using tools like Microsoft Excel or Google Sheets for basic inventory tracking, demand forecasting, and supplier management.

- Accounting Software ● Integrating accounting software with inventory management to track costs, sales, and profitability related to the supply chain.

- Basic E-Commerce Platforms ● Utilizing e-commerce platforms with built-in order management and shipping tools for online sales.

- Communication Tools ● Leveraging email, messaging apps, and project management software to improve communication with suppliers, customers, and internal teams.

In conclusion, even at a fundamental level, an SMB Supply Chain Strategy is about taking a deliberate and organized approach to managing the flow of goods and information in your business. It’s about making smart choices in sourcing, production, inventory, logistics, and customer service to achieve efficiency, cost savings, and customer satisfaction. By focusing on these core components, SMBs can build a solid foundation for growth and long-term success.

Intermediate

Building upon the foundational understanding of SMB Supply Chain Strategy, we now delve into an intermediate level, exploring more nuanced aspects and strategic considerations. At this stage, SMBs are likely experiencing growth, facing increased complexity, and recognizing the need for a more sophisticated approach to their supply chain. The intermediate level of SMB Supply Chain Strategy is characterized by a proactive and data-driven approach, focusing on optimization, risk mitigation, and leveraging technology for enhanced visibility and control.

Moving beyond the basic operational focus, intermediate SMBs begin to view their supply chain as a strategic asset, capable of driving competitive advantage. This involves a shift from reactive problem-solving to proactive planning and continuous improvement. The emphasis moves towards:

- Process Optimization ● Streamlining and refining existing supply chain processes to eliminate waste, reduce lead times, and improve efficiency across all stages.

- Data-Driven Decision Making ● Utilizing data and analytics to gain deeper insights into supply chain performance, identify trends, and make informed decisions regarding inventory, sourcing, and logistics.

- Risk Management ● Proactively identifying and mitigating potential risks within the supply chain, such as supplier disruptions, transportation delays, and demand fluctuations.

- Technology Adoption ● Implementing more advanced technology solutions to automate processes, improve communication, and gain real-time visibility into supply chain operations.

- Collaboration and Integration ● Strengthening collaboration with suppliers and potentially integrating systems to improve information sharing and optimize the entire supply chain ecosystem.

For an intermediate SMB, the supply chain is no longer just a cost center to be minimized, but a potential source of value creation and competitive differentiation. By strategically managing their supply chain, these businesses can improve customer service, reduce operational costs, and enhance their ability to respond to market opportunities and challenges.

An intermediate SMB supply chain strategy leverages data, technology, and process optimization to proactively manage risks, enhance efficiency, and create competitive advantage.

Consider a growing e-commerce business that has moved beyond basic order fulfillment Meaning ● Order fulfillment, within the realm of SMB growth, automation, and implementation, signifies the complete process from when a customer places an order to when they receive it, encompassing warehousing, picking, packing, shipping, and delivery. and is now experiencing increased order volumes and expanding product lines. At this stage, simply relying on spreadsheets and manual processes becomes unsustainable. They need to implement more robust systems for inventory management, order processing, and shipping.

They also need to analyze sales data to forecast demand more accurately and optimize their inventory levels. Furthermore, they might need to diversify their supplier base to mitigate the risk of relying too heavily on a single source.

Advanced Inventory Management Techniques for Intermediate SMBs

Intermediate SMBs can benefit from implementing more advanced inventory management techniques to optimize stock levels and reduce costs. These techniques often involve leveraging data and technology for better forecasting and control.

Demand Forecasting with Data Analytics

Moving beyond simple historical averages, intermediate SMBs can utilize data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. to improve demand forecasting Meaning ● Demand forecasting in the SMB sector serves as a crucial instrument for proactive business management, enabling companies to anticipate customer demand for products and services. accuracy. This involves:

- Analyzing Sales Data ● Examining historical sales data to identify patterns, trends, and seasonality in demand. This can involve using statistical techniques to identify correlations and predict future demand based on past performance.

- Market Research and External Data ● Incorporating external data sources, such as market research reports, economic indicators, and competitor activity, to refine demand forecasts and anticipate market shifts.

- Demand Planning Software ● Utilizing specialized demand planning Meaning ● Demand planning within the context of Small and Medium-sized Businesses (SMBs) is a crucial process involving the accurate forecasting of product or service demand to ensure efficient inventory management and operational readiness for growth. software that can automate data analysis, generate forecasts, and allow for scenario planning and adjustments based on changing conditions.

- Collaborative Forecasting ● Sharing demand forecasts with key suppliers to improve their production planning and ensure timely delivery of materials and components.

Inventory Optimization Models

Intermediate SMBs can employ inventory optimization Meaning ● Inventory Optimization, within the realm of Small and Medium-sized Businesses (SMBs), is a strategic approach focused on precisely aligning inventory levels with anticipated demand, thereby minimizing holding costs and preventing stockouts. models to determine optimal stock levels and reorder points, minimizing holding costs while ensuring sufficient stock availability. Examples include:

- Safety Stock Calculation ● Calculating safety stock levels based on demand variability and lead time variability to buffer against unexpected fluctuations and prevent stockouts.

- Reorder Point Planning ● Setting reorder points based on lead times and demand forecasts to trigger replenishment orders at the right time, avoiding both stockouts and excess inventory.

- Economic Order Quantity (EOQ) with Refinements ● Applying EOQ models while considering factors like quantity discounts, storage capacity constraints, and fluctuating demand to optimize order quantities.

- Inventory Segmentation (ABC/XYZ Analysis) ● Segmenting inventory based on value (ABC analysis) and demand predictability (XYZ analysis) to apply differentiated inventory management strategies. For example, high-value, predictable items (AX) might be managed with JIT principles, while low-value, unpredictable items (CZ) might be stocked in larger quantities.

Warehouse Management Systems (WMS)

As inventory complexity grows, intermediate SMBs can benefit from implementing a Warehouse Management System (WMS) to improve warehouse efficiency and accuracy. A WMS can provide features such as:

- Inventory Tracking and Visibility ● Real-time tracking of inventory locations, quantities, and movements within the warehouse, providing accurate visibility into stock levels.

- Optimized Storage and Picking ● Optimizing warehouse layout and storage locations to improve space utilization and streamline picking processes.

- Automated Data Capture ● Using barcode scanning or RFID technology to automate data capture for receiving, putaway, picking, and shipping, reducing manual errors and improving efficiency.

- Order Fulfillment Management ● Managing order fulfillment processes within the warehouse, including wave picking, batch picking, and order consolidation, to optimize order processing speed and accuracy.

Strategic Supplier Relationship Management

At the intermediate level, supplier relationship management becomes more strategic, focusing on building long-term partnerships and leveraging supplier capabilities for mutual benefit.

Supplier Performance Management with KPIs

Intermediate SMBs implement robust supplier performance management systems using Key Performance Indicators (KPIs) to monitor and evaluate supplier performance objectively. Relevant KPIs might include:

- On-Time Delivery Rate ● Measuring the percentage of orders delivered on time and in full, reflecting supplier reliability and responsiveness.

- Quality Defect Rate ● Tracking the percentage of defective items received from suppliers, indicating product quality and consistency.

- Lead Time Compliance ● Monitoring supplier adherence to agreed-upon lead times, ensuring timely material availability for production or sales.

- Cost Performance ● Evaluating supplier pricing and cost competitiveness, as well as identifying opportunities for cost reduction through collaboration.

- Responsiveness and Communication ● Assessing supplier responsiveness to inquiries, problem-solving, and overall communication effectiveness.

Supplier Collaboration and Integration

Moving beyond transactional relationships, intermediate SMBs seek to collaborate more closely with strategic suppliers, fostering partnerships based on mutual trust and shared goals. This can involve:

- Information Sharing ● Sharing demand forecasts, production plans, and inventory data with suppliers to improve their planning and responsiveness.

- Joint Process Improvement Initiatives ● Collaborating with suppliers to identify and implement process improvements that benefit both parties, such as streamlining ordering processes or optimizing logistics.

- Supplier Development Programs ● Investing in supplier development programs to improve supplier capabilities in areas like quality, technology, or sustainability.

- Integrated Systems ● Exploring opportunities to integrate systems with key suppliers, such as EDI (Electronic Data Interchange) or API (Application Programming Interface) integrations, to automate data exchange and improve communication efficiency.

Risk Mitigation in the Supply Chain

Intermediate SMBs recognize the importance of proactively managing risks within their supply chain to ensure business continuity and resilience. This involves:

- Supplier Diversification ● Reducing reliance on single suppliers by diversifying the supplier base and establishing backup suppliers for critical materials or components.

- Geographic Risk Assessment ● Evaluating geographic risks associated with suppliers, such as political instability, natural disasters, or economic disruptions, and considering alternative sourcing locations.

- Contingency Planning ● Developing contingency plans to address potential supply chain disruptions, such as alternative sourcing strategies, buffer inventory, or flexible production capacity.

- Supply Chain Visibility Tools ● Utilizing technology solutions that provide greater visibility into the supply chain, allowing for early detection of potential disruptions and proactive response.

Technology for Intermediate SMB Supply Chains

Intermediate SMBs leverage a wider range of technology solutions to enhance their supply chain management Meaning ● Supply Chain Management, crucial for SMB growth, refers to the strategic coordination of activities from sourcing raw materials to delivering finished goods to customers, streamlining operations and boosting profitability. capabilities. These technologies often provide greater automation, visibility, and analytical capabilities.

- Enterprise Resource Planning (ERP) Systems ● Implementing integrated ERP systems that encompass modules for inventory management, purchasing, sales, and financials, providing a centralized platform for managing key business processes.

- Supply Chain Management (SCM) Software ● Utilizing specialized SCM software that offers advanced features for demand planning, inventory optimization, supplier management, and logistics management.

- Transportation Management Systems (TMS) ● Employing TMS solutions to optimize transportation routes, manage freight costs, and track shipments in real-time.

- Customer Relationship Management (CRM) Systems ● Integrating CRM systems with supply chain data to gain a holistic view of customer demand and improve order fulfillment and customer service.

- Business Intelligence (BI) and Analytics Tools ● Leveraging BI and analytics tools to analyze supply chain data, generate reports, and gain actionable insights for process improvement and strategic decision-making.

In summary, the intermediate level of SMB Supply Chain Strategy is about moving beyond basic operations and adopting a more strategic, data-driven, and technology-enabled approach. By focusing on process optimization, advanced inventory management, strategic supplier relationships, risk mitigation, and technology adoption, intermediate SMBs can build a more resilient, efficient, and competitive supply chain that supports their continued growth and success.

Advanced

The advanced discourse surrounding SMB Supply Chain Strategy transcends the operational and tactical considerations prevalent in practitioner-focused discussions. From an advanced perspective, SMB Supply Chain Strategy is not merely a functional area of business management, but a complex, dynamic, and strategically vital ecosystem that significantly impacts SMB performance, resilience, and long-term viability. Drawing upon rigorous research, empirical data, and cross-disciplinary insights, we define SMB Supply Chain Strategy scholarly as:

“A dynamically adaptive, multi-echelon network of interconnected entities ● encompassing suppliers, producers, distributors, and customers ● strategically orchestrated by a Small to Medium-sized Business to optimize the flow of goods, services, information, and capital, while concurrently fostering resilience, innovation, and sustainable value creation within the constraints of limited resources and unique SMB contextual factors, thereby contributing to sustained competitive advantage and organizational longevity.”

This definition, synthesized from diverse advanced perspectives, emphasizes several key facets that are often overlooked in simpler, operational definitions:

- Dynamic Adaptability ● Acknowledges the fluid and ever-changing nature of SMB environments and the necessity for supply chain strategies to be flexible and responsive to disruptions and market shifts.

- Multi-Echelon Network ● Recognizes the interconnectedness of various entities within the supply chain, extending beyond direct suppliers and customers to encompass a broader ecosystem.

- Strategic Orchestration ● Highlights the proactive and deliberate management of the supply chain as a strategic instrument for achieving business objectives, rather than a purely reactive function.

- Optimization of Flows ● Focuses on the holistic optimization of not just physical goods, but also information, services, and financial capital across the supply chain network.

- Resilience and Innovation ● Underscores the critical role of supply chain strategy in building organizational resilience to disruptions and fostering innovation as a source of competitive advantage.

- Sustainable Value Creation ● Emphasizes the importance of creating long-term value for all stakeholders, including customers, suppliers, employees, and the broader community, while considering environmental and social sustainability.

- SMB Contextual Factors ● Recognizes the unique constraints and characteristics of SMBs, such as limited resources, entrepreneurial culture, and agility, which shape the formulation and implementation of supply chain strategies.

This advanced definition moves beyond a linear, sequential view of the supply chain to embrace a network-centric, systems-thinking approach. It recognizes that SMB Supply Chain Strategy is not a static plan, but an ongoing process of adaptation, optimization, and value creation within a complex and dynamic environment. It also acknowledges the inherent resource constraints and unique operational realities of SMBs, necessitating tailored strategies that are both effective and feasible within their specific context.

Scholarly, SMB Supply Chain Strategy is a dynamic, adaptive network orchestrated to optimize flows, build resilience, foster innovation, and create sustainable value within SMB constraints.

To fully appreciate the advanced depth of SMB Supply Chain Strategy, we must explore its diverse perspectives, cross-sectorial influences, and potential business outcomes for SMBs. We will focus on the lens of Digital Transformation and Automation as a particularly salient and impactful influence on contemporary SMB supply chain strategy.

Digital Transformation and Automation ● A Paradigm Shift in SMB Supply Chain Strategy

Digital transformation, characterized by the integration of digital technologies across all facets of a business, is profoundly reshaping SMB Supply Chain Strategy. Automation, a key component of digital transformation, is particularly impactful, offering the potential to revolutionize SMB supply chain operations and strategic capabilities. However, the adoption and implementation of digital technologies and automation in SMB supply chains are not without their complexities and challenges.

Diverse Perspectives on Digital Transformation in SMB Supply Chains

Advanced research offers diverse perspectives Meaning ● Diverse Perspectives, in the context of SMB growth, automation, and implementation, signifies the inclusion of varied viewpoints, backgrounds, and experiences within the team to improve problem-solving and innovation. on the impact of digital transformation Meaning ● Digital Transformation for SMBs: Strategic tech integration to boost efficiency, customer experience, and growth. and automation on SMB supply chains:

- Efficiency and Cost Reduction Perspective ● This perspective, often rooted in operations management and industrial engineering, emphasizes the potential of digital technologies to streamline processes, reduce manual labor, minimize errors, and optimize resource utilization, leading to significant cost reductions and efficiency gains in SMB supply chains. Research in this area focuses on quantifying the impact of automation technologies like robotic process automation (RPA), automated guided vehicles (AGVs), and cloud-based inventory management systems on SMB operational performance.

- Agility and Responsiveness Perspective ● Drawing from supply chain management and strategic management literature, this perspective highlights how digital technologies enhance SMB supply chain agility and responsiveness to dynamic market demands and disruptions. Real-time data Meaning ● Instantaneous information enabling SMBs to make agile, data-driven decisions and gain a competitive edge. visibility, predictive analytics, and flexible manufacturing systems enabled by digital transformation allow SMBs to adapt quickly to changing customer needs, personalize products and services, and respond effectively to unforeseen events.

- Innovation and Value Creation Perspective ● This perspective, informed by innovation management and entrepreneurship research, emphasizes the role of digital transformation in fostering innovation and creating new value propositions within SMB supply chains. Digital platforms, data analytics, and collaborative technologies enable SMBs to develop new products and services, improve customer experiences, and create entirely new business models, transforming their supply chains from cost centers to value drivers.

- Sustainability and Ethical Considerations Perspective ● Emerging research in sustainable supply chain management and business ethics highlights the potential of digital technologies to promote environmental and social sustainability in SMB supply chains. Digital traceability systems, smart logistics solutions, and data-driven sustainability metrics enable SMBs to monitor and reduce their environmental footprint, improve ethical sourcing Meaning ● Ethical sourcing, in the SMB landscape, refers to a proactive supply chain management approach, ensuring suppliers adhere to ethical labor standards, environmental responsibility, and fair business practices. practices, and enhance supply chain transparency Meaning ● Knowing product origins & journey, fostering SMB trust & efficiency. and accountability.

- Socio-Technical Systems Perspective ● A more nuanced perspective, rooted in socio-technical systems theory, recognizes that digital transformation in SMB supply chains is not solely a technological endeavor, but also a social and organizational change Meaning ● Strategic SMB evolution through proactive disruption, ethical adaptation, and leveraging advanced change methodologies for sustained growth. process. This perspective emphasizes the importance of considering the human element, organizational culture, and workforce skills in the successful adoption and implementation of digital technologies. It highlights the need for SMBs to invest in employee training, foster a culture of digital literacy, and manage the organizational change associated with automation and digital transformation.

Cross-Sectorial Influences on SMB Digital Supply Chain Strategies

The influence of digital transformation on SMB Supply Chain Strategy is not uniform across all sectors. Different industries face unique challenges and opportunities in leveraging digital technologies. Cross-sectorial analysis reveals distinct patterns and influences:

- Manufacturing Sector ● SMB manufacturers are increasingly adopting automation technologies in production processes, such as robotics, 3D printing, and IoT-enabled machinery, to improve efficiency, reduce costs, and enhance product quality. Digital supply chain Meaning ● Digital Supply Chain for SMBs: Integrating digital tech to streamline operations, enhance visibility, and drive growth in a scalable, cost-effective way. platforms are also being used to improve supplier collaboration, optimize inventory management, and enhance production planning and scheduling.

- Retail and E-Commerce Sector ● Digital transformation is fundamentally reshaping the retail and e-commerce sector. SMB retailers are leveraging e-commerce platforms, digital marketing tools, and data analytics to reach wider customer bases, personalize customer experiences, and optimize online order fulfillment. Automation in warehousing and logistics, such as automated picking and packing systems and drone delivery, is also gaining traction in this sector.

- Food and Agriculture Sector ● Digital technologies are transforming the food and agriculture supply chain, from farm to fork. SMBs in this sector are adopting precision agriculture techniques, IoT-enabled sensors for monitoring crop conditions and livestock health, and blockchain technology for food traceability and transparency. E-commerce platforms and direct-to-consumer models are also enabling SMB food producers to reach new markets and build closer relationships with customers.

- Healthcare Sector ● Digital transformation in healthcare supply chains is focused on improving patient care, reducing costs, and enhancing supply chain resilience. SMBs in the healthcare sector are adopting digital inventory management systems for pharmaceuticals and medical supplies, telehealth platforms for remote patient monitoring, and 3D printing for personalized medical devices. Blockchain technology is also being explored for secure and transparent tracking of pharmaceuticals and medical devices.

- Services Sector ● While often less tangible than product-based supply chains, service sector SMBs are also experiencing digital transformation in their service delivery and operations. Cloud-based service platforms, customer relationship management Meaning ● CRM for SMBs is about building strong customer relationships through data-driven personalization and a balance of automation with human touch. (CRM) systems, and remote service technologies are enabling SMB service providers to improve service efficiency, personalize service offerings, and reach wider customer bases. Data analytics is also being used to optimize service delivery processes and improve customer satisfaction.

These cross-sectorial examples illustrate that the specific digital technologies and automation strategies adopted by SMBs are highly context-dependent, influenced by industry-specific challenges, customer expectations, and regulatory requirements. A one-size-fits-all approach to digital transformation in SMB supply chains is unlikely to be effective. Instead, SMBs need to carefully assess their specific industry context, business needs, and resource constraints to develop tailored digital supply chain strategies.

Business Outcomes for SMBs Embracing Digital Supply Chain Strategies

The potential business outcomes for SMBs that strategically embrace digital transformation and automation in their supply chains are substantial and multifaceted:

- Enhanced Operational Efficiency Meaning ● Maximizing SMB output with minimal, ethical input for sustainable growth and future readiness. and Productivity ● Automation of repetitive tasks, streamlined processes, and real-time data visibility lead to significant improvements in operational efficiency and productivity across the supply chain. This translates to reduced lead times, faster order fulfillment, lower error rates, and optimized resource utilization.

- Improved Customer Experience and Satisfaction ● Digital technologies enable SMBs to personalize customer interactions, offer enhanced product and service customization, provide real-time order tracking and updates, and improve customer service responsiveness. These improvements contribute to higher customer satisfaction, increased customer loyalty, and positive word-of-mouth referrals.

- Increased Agility and Resilience to Disruptions ● Digital supply chains are inherently more agile and resilient due to real-time data visibility, predictive analytics, and flexible operational capabilities. SMBs with digitally transformed supply chains are better equipped to anticipate and respond to disruptions, adapt to changing market conditions, and maintain business continuity in the face of unforeseen events.

- Data-Driven Decision Making and Strategic Insights ● Digital transformation generates vast amounts of data across the supply chain. SMBs that effectively leverage data analytics and business intelligence tools can gain valuable insights into supply chain performance, customer behavior, market trends, and potential risks and opportunities. This data-driven decision-making capability enhances strategic planning, resource allocation, and overall business performance.

- New Revenue Streams and Business Model Innovation ● Digital technologies can enable SMBs to develop new revenue streams and innovate their business models. E-commerce platforms, digital marketplaces, and direct-to-consumer models open up new market opportunities. Data-driven services, personalized product offerings, and subscription-based models can create new value propositions and revenue streams.

- Enhanced Sustainability and Ethical Practices ● Digital technologies can support SMBs in achieving their sustainability goals and improving ethical sourcing practices. Digital traceability systems, smart logistics solutions, and data-driven sustainability metrics enable SMBs to monitor and reduce their environmental footprint, ensure ethical sourcing, and enhance supply chain transparency and accountability, appealing to increasingly environmentally and socially conscious customers.

However, it is crucial to acknowledge that the successful realization of these business outcomes requires careful planning, strategic implementation, and ongoing adaptation. SMBs must overcome several challenges in their digital transformation journey.

Challenges and Implementation Strategies for Digital Transformation in SMB Supply Chains

While the potential benefits of digital transformation in SMB Supply Chain Strategy are compelling, SMBs often face significant challenges in adopting and implementing digital technologies. These challenges and corresponding implementation strategies are critical to consider:

Challenges in Digital Transformation for SMB Supply Chains

- Limited Financial Resources ● SMBs typically have limited financial resources compared to large enterprises, making significant investments in digital technologies and automation challenging. The upfront costs of software, hardware, implementation services, and ongoing maintenance can be a significant barrier.

- Lack of Technical Expertise and Skills ● SMBs often lack in-house technical expertise and skills required to select, implement, and manage complex digital technologies. Finding and retaining skilled IT professionals or relying on external consultants can be costly and challenging.

- Integration Complexity with Legacy Systems ● Many SMBs operate with legacy IT systems that are not easily integrated with modern digital technologies. Integrating new digital solutions with existing systems can be complex, time-consuming, and expensive.

- Resistance to Change and Organizational Culture ● Digital transformation often requires significant organizational change, including process redesign, workforce upskilling, and cultural shifts. Resistance to change from employees and management can hinder the successful adoption of digital technologies.

- Data Security and Cybersecurity Concerns ● Increased reliance on digital technologies and data connectivity raises concerns about data security Meaning ● Data Security, in the context of SMB growth, automation, and implementation, represents the policies, practices, and technologies deployed to safeguard digital assets from unauthorized access, use, disclosure, disruption, modification, or destruction. and cybersecurity risks. SMBs may lack the resources and expertise to effectively protect their digital assets and sensitive data from cyber threats.

- Lack of Clear Digital Strategy Meaning ● A dynamic framework transforming SMBs via digital tech for growth & competitive edge. and Vision ● Some SMBs may lack a clear digital strategy and vision for their supply chain transformation. Without a well-defined roadmap and objectives, digital transformation initiatives can become fragmented, ineffective, and fail to deliver the expected benefits.

Implementation Strategies for Successful Digital Transformation

To overcome these challenges and successfully implement digital transformation in their supply chains, SMBs should adopt strategic and pragmatic implementation approaches:

- Phased and Incremental Implementation ● Instead of attempting a large-scale, “big bang” digital transformation, SMBs should adopt a phased and incremental approach. Start with pilot projects in specific areas of the supply chain, demonstrate early successes, and gradually expand digital initiatives based on proven value and ROI.

- Cloud-Based and SaaS Solutions ● Leverage cloud-based and Software-as-a-Service (SaaS) solutions to minimize upfront investment, reduce IT infrastructure costs, and access enterprise-grade digital technologies on a subscription basis. Cloud solutions offer scalability, flexibility, and ease of deployment, making them particularly suitable for SMBs.

- Focus on User-Friendly and Intuitive Technologies ● Select digital technologies that are user-friendly, intuitive, and require minimal specialized technical skills to operate. Prioritize solutions with easy-to-use interfaces, clear documentation, and readily available support resources.

- Invest in Employee Training Meaning ● Employee Training in SMBs is a structured process to equip employees with necessary skills and knowledge for current and future roles, driving business growth. and Upskilling ● Recognize that digital transformation is also a people transformation. Invest in employee training and upskilling programs to develop digital literacy, enhance technical skills, and foster a culture of digital adoption and innovation.

- Prioritize Data Security and Cybersecurity ● Implement robust data security and cybersecurity measures to protect digital assets and sensitive data. Partner with cybersecurity experts, adopt industry best practices, and regularly update security protocols to mitigate cyber risks.

- Develop a Clear Digital Strategy and Roadmap ● Develop a clear digital strategy and roadmap aligned with overall business objectives. Define specific goals for digital transformation, prioritize initiatives based on business impact and feasibility, and establish metrics to track progress and measure success.

- Seek External Expertise and Partnerships ● Don’t hesitate to seek external expertise and partnerships to support digital transformation initiatives. Engage with consultants, technology vendors, industry associations, and government support programs to access specialized knowledge, resources, and funding opportunities.

- Embrace a Culture of Experimentation Meaning ● Within the context of SMB growth, automation, and implementation, a Culture of Experimentation signifies an organizational environment where testing new ideas and approaches is actively encouraged and systematically pursued. and Learning ● Foster a culture of experimentation and learning within the organization. Encourage employees to explore new digital technologies, experiment with innovative solutions, and learn from both successes and failures. Embrace agile methodologies and iterative development approaches to facilitate rapid prototyping and continuous improvement.

By strategically addressing these challenges and adopting pragmatic implementation strategies, SMBs can effectively leverage digital transformation and automation to build more resilient, efficient, and competitive supply chains, unlocking significant business value and achieving sustainable growth in the digital age.

In conclusion, the advanced perspective on SMB Supply Chain Strategy, particularly through the lens of digital transformation and automation, reveals a complex and dynamic landscape. It underscores the need for SMBs to move beyond traditional operational approaches and embrace strategic, data-driven, and technology-enabled supply chain management. By understanding the diverse perspectives, cross-sectorial influences, and potential business outcomes of digital transformation, and by proactively addressing the challenges and adopting effective implementation strategies, SMBs can harness the transformative power of digital technologies to build world-class supply chains that drive competitive advantage and long-term success in the 21st century.