Fundamentals

For small to medium-sized businesses (SMBs), the term ‘Inventory Innovation’ might sound complex or intimidating, conjuring images of intricate software and expensive consultants. However, at its core, SMB Inventory Innovation is simply about finding smarter, more efficient ways to manage what you sell or use to create your products. It’s about moving beyond outdated methods and embracing changes that help your business thrive. Imagine a local bakery that used to manually count all its flour, sugar, and chocolate every week.

Inventory Innovation for them might be as simple as implementing a basic spreadsheet to track these ingredients, reducing errors and saving valuable time. This section will demystify inventory innovation, showing you how even small changes can make a big difference.

Understanding the Basics of Inventory Management for SMBs

Before we delve into innovation, it’s crucial to understand the fundamentals of inventory management Meaning ● Inventory management, within the context of SMB operations, denotes the systematic approach to sourcing, storing, and selling inventory, both raw materials (if applicable) and finished goods. itself. For any SMB, regardless of industry, inventory management is the process of ordering, storing, using, and selling a company’s inventory. This includes raw materials, components, and finished products, as well as the warehousing and processing of such items. Effective inventory management aims to ensure that you have the right products in the right quantities at the right time and place.

This might seem obvious, but getting it wrong can lead to significant problems for SMBs. Too much inventory ties up cash in unsold goods and increases storage costs. Too little inventory leads to lost sales, dissatisfied customers, and potentially damaged business reputation. Therefore, mastering the basics is the first step towards meaningful inventory innovation.

Consider these key aspects of basic inventory management:

- Tracking Stock Levels ● Knowing exactly what you have on hand, where it is located, and in what quantity is fundamental. This can range from simple visual checks in a small shop to using basic spreadsheets for slightly larger operations.

- Demand Forecasting ● Predicting how much of each product you’ll need in the future. For a small coffee shop, this might be based on past sales data and seasonal trends (more iced coffee in summer, hot coffee in winter). Even simple estimations are better than no planning at all.

- Ordering and Replenishment ● Establishing a system for reordering inventory before you run out. This involves determining reorder points (when to reorder) and order quantities (how much to reorder). For a retail boutique, this could mean setting a reminder to reorder popular clothing items when stock levels fall below a certain threshold.

- Storage and Warehousing ● Organizing your inventory in a way that is efficient and minimizes damage or loss. For a small online retailer operating from home, this might simply mean using shelves and boxes in a spare room, organized logically by product type.

For SMBs, mastering basic inventory management is the crucial first step towards embracing more innovative and efficient practices.

Why is Inventory Innovation Important for SMB Growth?

In today’s competitive landscape, SMBs cannot afford to rely on outdated or inefficient processes, especially when it comes to inventory. Inventory Innovation is not just a buzzword; it’s a necessity for sustainable growth and profitability. For SMBs operating on tight margins and with limited resources, even small improvements in inventory management can have a significant impact on the bottom line. Think about a small restaurant struggling with food waste.

By implementing better inventory tracking and ordering practices, they can reduce spoilage, lower food costs, and increase their profit margins. This saved money can then be reinvested into other areas of the business, fueling growth.

Here’s why Inventory Innovation is a critical driver of SMB growth:

- Reduced Costs ● Efficient inventory management minimizes waste, reduces storage expenses, and prevents stockouts that can lead to lost sales. For example, a clothing store that accurately predicts demand can avoid overstocking seasonal items that will need to be heavily discounted later, preserving profit margins.

- Improved Cash Flow ● By optimizing inventory levels, SMBs can free up cash that would otherwise be tied up in excess stock. This improved cash flow can be used for other critical business needs, such as marketing, hiring, or investing in new equipment. A small manufacturing business, by streamlining its raw material inventory, can have more cash available to invest in upgrading its machinery.

- Enhanced Customer Satisfaction ● Having the right products available when customers want them is crucial for customer satisfaction and loyalty. Inventory Innovation helps SMBs avoid stockouts and ensure timely order fulfillment, leading to happier customers and repeat business. An online bookstore with efficient inventory management can ensure that popular titles are always in stock and shipped promptly, leading to positive customer reviews and increased sales.

- Increased Efficiency and Productivity ● Automating or streamlining inventory processes frees up valuable time for business owners and employees to focus on more strategic tasks, such as sales, marketing, and customer service. A small hardware store that implements a barcode scanning system for inventory can significantly reduce the time spent on manual stocktaking, allowing staff to spend more time assisting customers.

- Better Decision-Making ● Inventory Innovation often involves leveraging data and analytics to gain deeper insights into sales trends, customer demand, and inventory performance. This data-driven approach empowers SMBs to make more informed decisions about purchasing, pricing, and marketing strategies. A local toy store, by analyzing its sales data, can identify its best-selling toys and adjust its inventory accordingly, maximizing sales during peak seasons.

Simple Steps to Begin Inventory Innovation for Your SMB

Starting your inventory innovation journey doesn’t require a massive overhaul or significant investment. Small, incremental changes can yield substantial results. The key is to start simple, focus on your most pressing inventory challenges, and gradually build upon your successes.

Many SMBs are hesitant to adopt new technologies or processes, fearing complexity or cost. However, there are numerous affordable and user-friendly tools and techniques available that can make inventory innovation accessible to even the smallest businesses.

Here are some practical steps to get started with inventory innovation:

- Assess Your Current Inventory Process ● Before making any changes, understand your current system. How do you track inventory? How do you forecast demand? What are your biggest inventory challenges? Simply observing and documenting your current process is the first step towards identifying areas for improvement. For a small clothing boutique, this might involve tracking sales manually for a week and noting down any instances of stockouts or overstocking.

- Implement a Basic Inventory Tracking System ● If you’re still relying on manual methods, consider adopting a simple digital system. Spreadsheets are a great starting point for many SMBs. There are also affordable inventory management apps designed specifically for small businesses that offer features like barcode scanning and reporting. A small craft store can start by using a spreadsheet to list all its products, track quantities, and record sales, gradually moving towards a more dedicated inventory app as the business grows.

- Focus on Data Collection ● Start collecting data on your sales, inventory levels, and customer demand. Even basic data, like monthly sales figures for each product, can provide valuable insights over time. This data will be crucial for making informed decisions about inventory management in the future. A small bakery can start tracking daily sales of each type of pastry to understand which items are most popular and when.

- Automate Repetitive Tasks ● Identify manual inventory tasks that can be automated. For example, setting up automatic reorder points in your inventory system can save time and prevent stockouts. Using barcode scanners can speed up stocktaking and reduce errors. A small retail store can use barcode scanners at checkout to automatically update inventory levels, eliminating the need for manual data entry.

- Seek Employee Feedback ● Your employees who work directly with inventory often have valuable insights into inefficiencies and potential improvements. Involve them in the innovation process and encourage their suggestions. A restaurant manager can ask kitchen staff for feedback on ingredient storage and usage to identify areas for waste reduction.

Inventory Innovation for SMBs is not about overnight transformations. It’s about continuous improvement and adapting to the changing needs of your business and your customers. By starting with these fundamental steps and gradually embracing more advanced techniques, SMBs can unlock significant benefits and position themselves for sustained growth and success.

Small, incremental changes, focused on addressing specific SMB challenges, are the most effective way to begin the journey of inventory innovation.

Intermediate

Building upon the fundamentals, the intermediate stage of SMB Inventory Innovation delves into more sophisticated strategies and tools. At this level, SMBs are ready to move beyond basic spreadsheets and manual processes, embracing automation and data-driven decision-making to optimize their inventory management. We’re not just talking about tracking stock anymore; we’re focusing on strategic inventory deployment to enhance operational efficiency, improve profitability, and gain a competitive edge.

Imagine a growing e-commerce business that started with simple inventory tracking but now faces challenges with order fulfillment Meaning ● Order fulfillment, within the realm of SMB growth, automation, and implementation, signifies the complete process from when a customer places an order to when they receive it, encompassing warehousing, picking, packing, shipping, and delivery. speed and accuracy. Intermediate inventory innovation for them might involve implementing a cloud-based inventory management system integrated with their e-commerce platform, enabling real-time stock updates, automated order processing, and streamlined shipping.

Advanced Inventory Management Techniques for Growing SMBs

As SMBs grow, their inventory management needs become more complex. Simple methods that worked in the early stages may no longer be sufficient to handle increased volume, product variety, and customer expectations. Intermediate inventory innovation involves adopting more advanced techniques to manage this complexity effectively. These techniques are not necessarily about complex software or expensive consultants, but rather about applying proven methodologies in a smart and strategic way tailored to the SMB context.

Here are some key advanced inventory management techniques relevant for growing SMBs:

- ABC Analysis ● This technique categorizes inventory items into three groups (A, B, and C) based on their value and consumption rate. ‘A Items’ are high-value items that account for a significant portion of total inventory value and require close monitoring and tight control. ‘B Items’ are medium-value items with moderate consumption rates, requiring less stringent control than A items. ‘C Items’ are low-value items with low consumption rates, requiring minimal control. For a retail store, A items might be high-end electronics, B items could be mid-range appliances, and C items might be low-cost accessories. ABC analysis helps SMBs prioritize their inventory management efforts, focusing resources on the most important items.

- Economic Order Quantity (EOQ) ● EOQ is a formula used to calculate the optimal order quantity that minimizes total inventory costs, including ordering costs and holding costs. While the formula itself might seem complex, the underlying principle is straightforward ● finding the sweet spot between ordering too much (leading to high holding costs) and ordering too little (leading to frequent ordering costs and potential stockouts). For a manufacturing SMB, EOQ can help determine the most cost-effective quantity of raw materials to order at a time, balancing bulk discounts with storage limitations.

- Just-In-Time (JIT) Inventory ● JIT is an inventory management philosophy that aims to minimize inventory holding by receiving goods only when they are needed for production or sale. This approach requires close coordination with suppliers and highly efficient processes. While full JIT implementation might be challenging for some SMBs, adopting JIT principles can significantly reduce inventory levels and improve efficiency. A restaurant can apply JIT principles by ordering fresh produce daily based on predicted customer demand, minimizing spoilage and ensuring freshness.

- Safety Stock Management ● Safety stock is extra inventory held to buffer against unexpected fluctuations in demand or supply. Determining the right level of safety stock is crucial to avoid stockouts without holding excessive inventory. Factors to consider include demand variability, lead time variability, and desired service level. An e-commerce business selling seasonal products might increase safety stock levels before peak seasons to ensure they can meet anticipated surges in demand.

- Demand Forecasting with Data Analytics ● Moving beyond simple estimations, intermediate inventory innovation leverages data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. to improve demand forecasting Meaning ● Demand forecasting in the SMB sector serves as a crucial instrument for proactive business management, enabling companies to anticipate customer demand for products and services. accuracy. This involves analyzing historical sales data, seasonal trends, market trends, and even external factors like weather patterns or local events to predict future demand. SMBs can use readily available data analytics tools or even spreadsheet software to perform basic demand forecasting. A local ice cream shop can analyze past sales data and weather forecasts to predict demand for different flavors on different days, optimizing ingredient ordering and production.

Advanced inventory management techniques, when strategically applied, empower growing SMBs to optimize inventory levels, reduce costs, and enhance operational efficiency.

Leveraging Technology for Inventory Automation in SMBs

Technology plays a pivotal role in intermediate inventory innovation, particularly in automating repetitive tasks and improving data accuracy. For SMBs, automation is not about replacing human workers but about empowering them to focus on higher-value activities by streamlining routine processes. The right technology can significantly reduce manual errors, improve efficiency, and provide real-time visibility into inventory levels, enabling faster and more informed decision-making.

Here are key technological solutions for inventory automation in SMBs:

- Cloud-Based Inventory Management Systems ● These systems offer a centralized platform to manage inventory across multiple locations, track stock levels in real-time, automate order processing, generate reports, and integrate with other business systems like e-commerce platforms and accounting software. Cloud-based solutions are often more affordable and scalable for SMBs compared to traditional on-premise systems. A small chain of retail stores can use a cloud-based system to manage inventory across all locations, track sales data centrally, and automate replenishment orders.

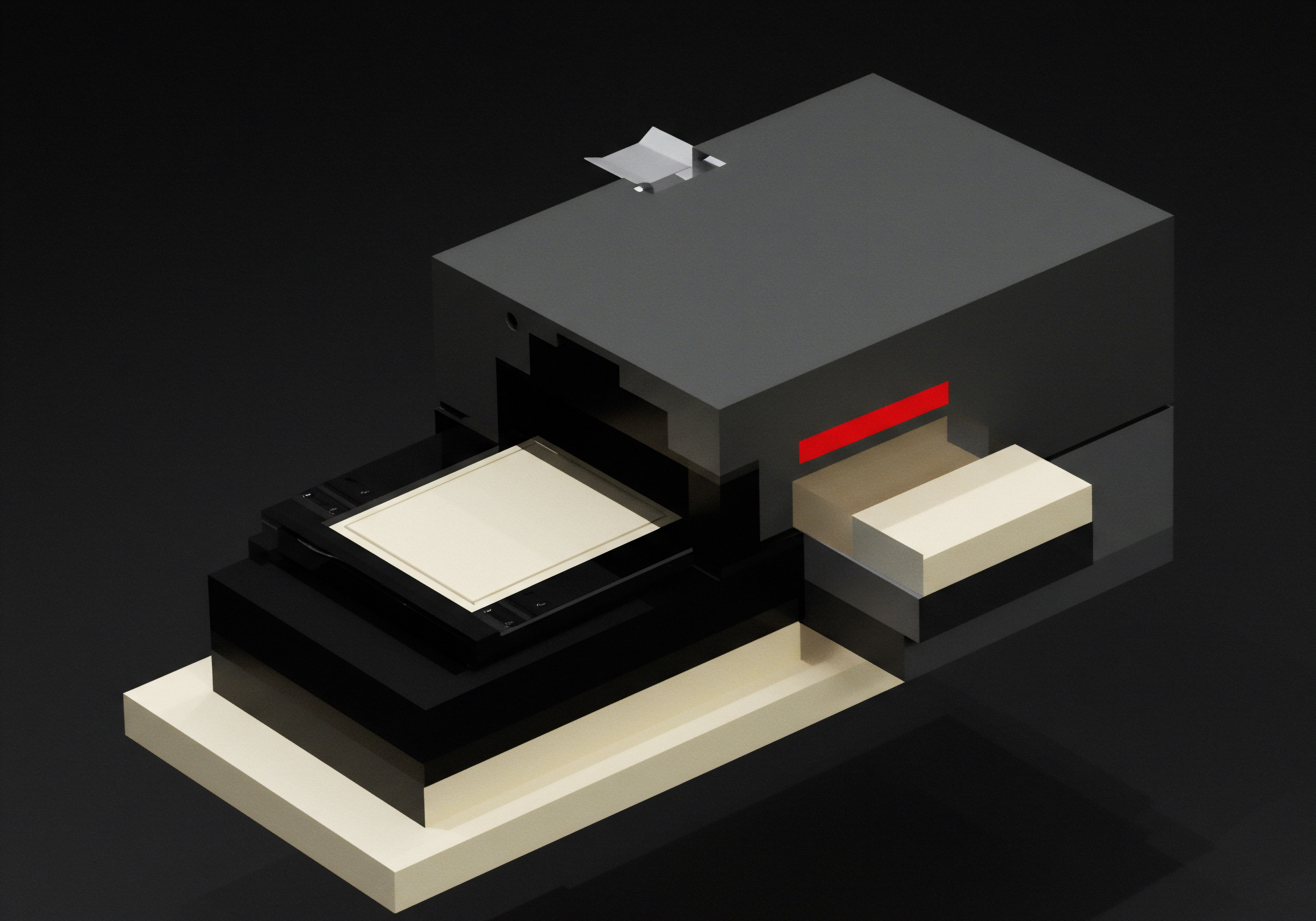

- Barcode and RFID Technology ● Barcode scanners and RFID (Radio-Frequency Identification) tags significantly speed up inventory tracking and reduce data entry errors. Barcode scanners are cost-effective for most SMBs and can be used for receiving inventory, conducting stocktakes, and processing sales. RFID technology, while more expensive, offers even faster and more accurate tracking, particularly for businesses with large volumes of inventory or complex warehousing operations. A warehouse for a distribution SMB can use barcode scanners to quickly receive and track incoming shipments, improving receiving efficiency and accuracy.

- Point of Sale (POS) Integration ● Integrating your POS system with your inventory management system ensures that sales data is automatically updated in real-time, providing accurate and up-to-date inventory levels. This integration eliminates manual data entry, reduces errors, and provides valuable sales data for demand forecasting and inventory planning. A retail store with a POS system integrated with its inventory management software will automatically update stock levels every time a sale is made, providing real-time inventory visibility.

- Mobile Inventory Apps ● Mobile apps extend inventory management capabilities to smartphones and tablets, allowing employees to perform inventory tasks on the go, such as stocktaking, receiving goods, and fulfilling orders. Mobile apps improve efficiency and flexibility, particularly for businesses with mobile workforces or multiple locations. Field technicians for a service-based SMB can use a mobile inventory app to track their van stock, update inventory levels after each job, and request replenishment orders remotely.

- Automated Reporting and Analytics ● Advanced inventory management systems offer automated reporting and analytics features that provide insights into inventory performance, sales trends, and demand patterns. These reports can help SMBs identify slow-moving items, optimize stock levels, and make data-driven decisions about purchasing and pricing. An e-commerce SMB can use automated reports to track inventory turnover rates, identify best-selling products, and optimize its product catalog.

Optimizing Inventory Processes for Enhanced SMB Efficiency

Beyond technology, intermediate inventory innovation also involves optimizing inventory processes to streamline workflows, reduce bottlenecks, and improve overall efficiency. This requires a critical review of existing processes, identification of areas for improvement, and implementation of best practices tailored to the specific needs and context of the SMB.

Key areas for process optimization include:

- Streamlining the Procurement Process ● Optimizing the process of ordering and receiving inventory can significantly reduce lead times, improve supplier relationships, and minimize ordering costs. This includes negotiating favorable terms with suppliers, establishing clear ordering procedures, and automating purchase order generation. A manufacturing SMB can streamline its procurement process by establishing long-term contracts with key suppliers, negotiating volume discounts, and implementing electronic data interchange (EDI) for faster order processing.

- Improving Warehouse Layout and Organization ● An efficient warehouse layout and organization can significantly reduce picking and packing times, minimize errors, and improve space utilization. This involves optimizing storage locations based on product velocity, implementing clear labeling and signage, and using efficient picking and packing methods. A distribution SMB can optimize its warehouse layout by implementing ABC zoning, placing fast-moving items in easily accessible locations, and using pick-to-light systems to guide order pickers.

- Implementing Cycle Counting ● Cycle counting is a regular process of counting a small portion of inventory on a daily or weekly basis, rather than conducting a full physical inventory count periodically. Cycle counting improves inventory accuracy, identifies discrepancies early, and reduces disruptions to operations compared to full physical counts. A retail store can implement cycle counting by counting a section of its store inventory each day, ensuring that the entire inventory is counted and verified regularly.

- Optimizing Order Fulfillment Processes ● Streamlining order fulfillment processes, from order picking to shipping, is crucial for meeting customer expectations and minimizing fulfillment costs. This includes optimizing picking routes, using efficient packing materials, and selecting appropriate shipping methods. An e-commerce SMB can optimize its order fulfillment process by implementing batch picking, using automated packing machines, and offering multiple shipping options to customers.

- Regularly Reviewing and Refining Processes ● Inventory process optimization is not a one-time project but an ongoing process of continuous improvement. SMBs should regularly review their inventory processes, identify areas for further optimization, and adapt their processes to changing business needs and customer demands. A growing SMB should periodically review its inventory management system and processes to ensure they remain efficient and scalable as the business expands.

By embracing advanced techniques, leveraging technology, and optimizing processes, SMBs can achieve significant improvements in inventory management, leading to enhanced efficiency, reduced costs, improved customer satisfaction, and ultimately, sustainable growth.

Intermediate inventory innovation empowers SMBs to move beyond basic methods, leveraging technology and advanced techniques for strategic inventory management and operational excellence.

Advanced

Advanced SMB Inventory Innovation transcends mere efficiency gains; it’s about strategically leveraging inventory as a dynamic asset to drive competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. and foster long-term resilience. At this expert level, we move beyond tactical optimizations and delve into the strategic implications of inventory within the broader SMB ecosystem. This involves a deep understanding of complex supply chain dynamics, predictive analytics, and the integration of inventory management with overarching business strategies. Imagine a sophisticated SMB manufacturer operating in a volatile global market.

Advanced inventory innovation for them is not just about minimizing holding costs, but about building resilient supply chains, using predictive analytics to anticipate market shifts, and strategically positioning inventory to capitalize on emerging opportunities and mitigate risks. This section will explore the nuances of advanced inventory innovation, focusing on strategic foresight, adaptive systems, and the creation of a truly intelligent inventory function within the SMB.

Redefining SMB Inventory Innovation ● A Strategic Asset, Not Just a Cost Center

Traditionally, inventory has often been viewed as a necessary evil ● a cost to be minimized. However, advanced SMB Inventory Innovation challenges this perspective, reframing inventory as a strategic asset that can be actively managed to generate value and drive competitive advantage. This paradigm shift requires a fundamental change in mindset, moving from a reactive, cost-focused approach to a proactive, value-driven strategy. For expert-level SMBs, inventory is not just about stock levels; it’s about strategic positioning in the market, responsiveness to customer needs, and building a resilient supply chain that can weather disruptions and capitalize on opportunities.

From an advanced perspective, SMB Inventory Innovation can be redefined as:

“The strategic and dynamic orchestration of inventory resources within an SMB ecosystem, leveraging advanced analytics, adaptive systems, and proactive planning to transform inventory from a cost center into a value-generating asset, driving competitive advantage, enhancing customer responsiveness, and fostering long-term business resilience in a complex and volatile market environment.”

This advanced definition encompasses several key dimensions:

- Strategic Orchestration ● Inventory management is not an isolated function but is intricately linked to overall business strategy. Advanced innovation involves aligning inventory decisions with strategic goals, such as market penetration, product differentiation, or customer service Meaning ● Customer service, within the context of SMB growth, involves providing assistance and support to customers before, during, and after a purchase, a vital function for business survival. excellence. For a high-growth tech SMB, strategic inventory orchestration might involve pre-positioning inventory in key geographic markets to support rapid expansion and ensure timely product delivery to new customers.

- Dynamic Resource Management ● Inventory is viewed as a dynamic resource that needs to be actively managed and adjusted in response to changing market conditions, customer demand, and supply chain dynamics. This requires agility and responsiveness, moving away from static inventory policies to adaptive and flexible approaches. For an SMB in the fashion industry, dynamic inventory management means quickly adjusting production and inventory levels in response to fast-changing fashion trends and seasonal demand fluctuations.

- Advanced Analytics and Predictive Capabilities ● Leveraging sophisticated data analytics and predictive modeling to gain deeper insights into demand patterns, market trends, and supply chain risks. This enables proactive decision-making, anticipating future needs and challenges, rather than reacting to past events. For an SMB retailer, advanced analytics Meaning ● Advanced Analytics, in the realm of Small and Medium-sized Businesses (SMBs), signifies the utilization of sophisticated data analysis techniques beyond traditional Business Intelligence (BI). can be used to predict demand for specific products at individual store locations, optimizing inventory allocation and minimizing stockouts and overstocking.

- Value Generation and Competitive Advantage ● Inventory is actively managed to create value for the business, not just minimize costs. This includes using inventory to enhance customer service, improve product availability, reduce lead times, and differentiate the business from competitors. For an SMB distributor, offering faster delivery times and higher order fulfillment rates than competitors through strategic inventory positioning can be a key source of competitive advantage.

- Resilience and Risk Mitigation ● Building resilient supply chains Meaning ● Dynamic SMB networks adapting to disruptions, ensuring business continuity and growth. and inventory systems that can withstand disruptions, such as supply chain shocks, economic downturns, or unexpected events. This involves diversifying suppliers, building buffer inventories strategically, and developing contingency plans for potential disruptions. For an SMB manufacturer reliant on global supply chains, building resilience might involve dual-sourcing critical components and maintaining safety stock of key raw materials to mitigate the impact of potential supply chain disruptions.

The Convergence of Advanced Technologies ● AI, IoT, and Blockchain in SMB Inventory Innovation

Advanced SMB Inventory Innovation is increasingly driven by the convergence of cutting-edge technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Blockchain. These technologies offer transformative capabilities that can revolutionize inventory management, enabling unprecedented levels of automation, visibility, and intelligence.

Here’s how these technologies are reshaping advanced inventory innovation:

- Artificial Intelligence (AI) and Machine Learning (ML) ● AI and ML algorithms can analyze vast datasets to identify complex patterns, predict future demand with greater accuracy, optimize inventory levels dynamically, and automate complex decision-making processes. ‘Demand Forecasting’ powered by AI can consider a multitude of factors, including historical sales data, weather patterns, social media trends, economic indicators, and competitor actions, to generate highly accurate demand predictions. ‘Inventory Optimization Algorithms’ can dynamically adjust safety stock levels, reorder points, and order quantities based on real-time demand fluctuations and supply chain conditions. ‘AI-Powered Chatbots’ can automate customer service inquiries related to inventory availability and order status, improving customer experience and freeing up human agents for more complex tasks.

- Internet of Things (IoT) and Sensor Networks ● IoT devices, such as sensors and RFID tags, provide real-time visibility into inventory location, condition, and movement throughout the supply chain. ‘Smart Shelves’ equipped with sensors can automatically track inventory levels and trigger replenishment alerts when stock levels fall below a certain threshold. ‘GPS-Enabled Tracking Devices’ can provide real-time visibility into the location of goods in transit, improving supply chain transparency Meaning ● Knowing product origins & journey, fostering SMB trust & efficiency. and reducing the risk of loss or theft. ‘Environmental Sensors’ can monitor temperature, humidity, and other environmental conditions in warehouses and storage facilities, ensuring that perishable goods are stored under optimal conditions and reducing spoilage.

- Blockchain Technology for Supply Chain Transparency and Security ● Blockchain provides a secure and transparent ledger for tracking inventory movements and verifying product authenticity throughout the supply chain. ‘Blockchain-Based Tracking Systems’ can provide end-to-end visibility into the provenance of goods, from origin to consumer, enhancing supply chain transparency and building trust. ‘Smart Contracts’ on blockchain can automate inventory transactions and payments, streamlining processes and reducing administrative overhead. ‘Blockchain can Enhance Security’ by providing an immutable record of inventory data, making it more difficult to tamper with or falsify information, reducing the risk of fraud and counterfeiting.

The synergistic combination of AI, IoT, and Blockchain creates a powerful ecosystem for advanced SMB Inventory Innovation, enabling truly intelligent, responsive, and resilient inventory management systems.

Strategic Inventory Deployment ● Location, Postponement, and Risk Pooling

Advanced inventory innovation extends beyond optimizing stock levels to strategically deploying inventory across the supply chain to maximize responsiveness, minimize costs, and mitigate risks. Strategic inventory deployment involves making critical decisions about where to hold inventory, when to customize products, and how to pool demand to reduce variability.

Key strategic inventory deployment strategies for advanced SMBs include:

- Inventory Location Strategy ● Centralized Vs. Decentralized ● Deciding whether to centralize inventory in a few large warehouses or decentralize it across multiple smaller distribution centers is a critical strategic decision. ‘Centralized Inventory’ can lead to lower overall inventory levels due to risk pooling, reduced warehousing costs, and greater control. However, it can also result in longer lead times and higher transportation costs, particularly for geographically dispersed customer bases. ‘Decentralized Inventory’ can provide faster delivery times and improved customer responsiveness, but it typically requires higher overall inventory levels and increased warehousing costs. The optimal inventory location strategy depends on factors such as customer service requirements, transportation costs, product characteristics, and demand patterns.

- Postponement Strategy ● Delayed Differentiation ● Postponement, also known as delayed differentiation, is a strategy that involves delaying product customization or final assembly until closer to the point of demand. ‘Postponement Reduces Inventory Risk’ by holding inventory in a generic or semi-finished form, allowing for greater flexibility to meet diverse customer demands. For example, a computer manufacturer might postpone final configuration of laptops until orders are received, holding inventory of generic components that can be assembled into different models based on customer specifications. ‘Postponement can Improve Responsiveness’ by enabling faster customization and delivery of products tailored to specific customer needs.

- Risk Pooling ● Demand Aggregation and Variability Reduction ● Risk pooling is a strategy that aims to reduce demand variability and improve forecasting accuracy by aggregating demand across multiple locations or product lines. ‘Demand Aggregation’ can be achieved by consolidating inventory in fewer locations, serving multiple markets from a central warehouse. ‘Product Pooling’ involves using common components or platforms across multiple products, reducing the variety of inventory items and simplifying inventory management. Risk pooling can significantly reduce safety stock requirements and improve overall inventory efficiency. For example, a retailer selling clothing in multiple stores can reduce overall inventory levels by pooling demand across stores and managing inventory centrally, rather than holding separate safety stock in each store.

Strategic inventory deployment is a powerful tool for advanced SMBs to optimize their supply chains, enhance customer service, and gain a competitive edge in the marketplace.

Building Resilient and Adaptive Inventory Systems for Volatile Markets

In today’s increasingly volatile and unpredictable global markets, building resilient and adaptive inventory systems is paramount for SMBs to thrive. Resilience refers to the ability of the inventory system to withstand disruptions and recover quickly, while adaptability refers to the ability to adjust to changing market conditions and customer demands.

Key strategies for building resilient and adaptive inventory systems include:

- Supply Chain Diversification and Redundancy ● Reducing reliance on single suppliers and building redundancy into the supply chain is crucial for mitigating supply chain risks. ‘Dual-Sourcing or Multi-Sourcing’ critical components or raw materials ensures that alternative sources of supply are available in case of disruptions. ‘Geographic Diversification of Suppliers’ reduces exposure to regional risks, such as natural disasters or political instability. ‘Building Buffer Inventories’ of critical items can provide a safety net in case of unexpected supply chain disruptions, although this needs to be balanced against holding costs.

- Demand Sensing and Real-Time Inventory Visibility ● Implementing systems that provide real-time visibility into demand signals and inventory levels is essential for rapid response to changing market conditions. ‘Demand Sensing Technologies’, such as POS data analytics and social media monitoring, can provide early warnings of shifts in customer demand. ‘Real-Time Inventory Tracking Systems’, enabled by IoT and cloud-based platforms, provide up-to-the-minute visibility into stock levels across the supply chain. This real-time information enables SMBs to adjust production plans, inventory levels, and pricing strategies quickly in response to market changes.

- Agile Inventory Management Processes and Flexible Systems ● Adopting agile inventory management processes and implementing flexible systems that can adapt to changing requirements is crucial for resilience and adaptability. ‘Agile Methodologies’, such as iterative planning and rapid prototyping, can be applied to inventory management to enable faster response to changing market conditions. ‘Modular Inventory Management Systems’ that can be easily reconfigured and scaled up or down provide greater flexibility. ‘Scenario Planning and Stress Testing’ inventory systems against potential disruptions can help identify vulnerabilities and develop contingency plans.

- Collaboration and Information Sharing Across the Supply Chain ● Enhanced collaboration and information sharing with suppliers, distributors, and customers is essential for building resilient and adaptive supply chains. ‘Collaborative Planning, Forecasting, and Replenishment (CPFR)’ initiatives can improve demand forecasting accuracy and reduce inventory bullwhip effect. ‘Supply Chain Visibility Platforms’ that enable real-time information sharing across the supply chain can improve coordination and responsiveness. ‘Building Strong Relationships with Key Suppliers and Customers’ fosters trust and enables faster communication and problem-solving in case of disruptions.

By embracing these advanced strategies, SMBs can transform their inventory systems from reactive cost centers to proactive strategic assets, building resilience, adaptability, and a sustainable competitive advantage in the dynamic and challenging business environment of the 21st century.

Advanced SMB Inventory Innovation is about strategically leveraging inventory as a dynamic asset, employing cutting-edge technologies, and building resilient, adaptive systems Meaning ● Adaptive Systems, in the SMB arena, denote frameworks built for inherent change and optimization, aligning technology with evolving business needs. to achieve sustained competitive advantage in volatile markets.