Fundamentals

In the bustling world of Small to Medium-Sized Businesses (SMBs), where resources are often stretched and every penny counts, understanding and improving how things get done is paramount. This is where the concept of Process Efficiency Metrics comes into play. Simply put, these metrics are tools that help SMB owners and managers see how well their business processes are performing. Think of them as the speedometer and fuel gauge for your business operations, indicating speed and resource consumption.

What are Process Efficiency Metrics?

At their core, Process Efficiency Metrics are quantifiable measurements used to evaluate the effectiveness and productivity of business processes. For an SMB, a process could be anything from handling customer inquiries, processing sales orders, managing inventory, or even onboarding new employees. Efficiency, in this context, is about doing things right, quickly, and with minimal waste.

It’s about maximizing output while minimizing input ● whether that input is time, money, effort, or resources. These metrics provide a clear, data-driven way to understand if your processes are helping your business thrive or holding it back.

Imagine a small bakery, for example. One crucial process is baking bread. Process Efficiency Metrics for this could include:

- Baking Time ● How long does it take to bake a batch of bread?

- Ingredient Waste ● How much dough or ingredients are wasted during preparation?

- Oven Utilization ● How effectively is the oven space being used?

By tracking these metrics, the bakery owner can identify areas for improvement. Perhaps they can adjust the baking process to reduce baking time, train staff to minimize ingredient waste, or optimize oven loading to bake more bread per batch. This simple example illustrates the fundamental purpose of Process Efficiency Metrics ● to pinpoint inefficiencies and guide improvements.

Why are Process Efficiency Metrics Important for SMBs?

For SMBs, the efficient use of resources is not just a good idea; it’s often a matter of survival and growth. Larger corporations might have the financial cushion to absorb inefficiencies, but SMBs typically operate with tighter margins. Therefore, understanding and optimizing processes through metrics is critically important for several reasons:

- Cost Reduction ● Inefficient processes waste resources ● time, money, and materials. By identifying and eliminating these inefficiencies, SMBs can significantly reduce operational costs. For instance, streamlining the invoice processing process can reduce administrative time and paper consumption, directly impacting the bottom line.

- Improved Productivity ● Efficient processes lead to increased output with the same or fewer inputs. This translates to higher productivity, meaning your team can accomplish more in less time. Think about a small e-commerce business; an efficient order fulfillment Meaning ● Order fulfillment, within the realm of SMB growth, automation, and implementation, signifies the complete process from when a customer places an order to when they receive it, encompassing warehousing, picking, packing, shipping, and delivery. process allows them to ship more orders per day with the same staff, increasing revenue potential.

- Enhanced Customer Satisfaction ● Efficient processes often result in faster service and higher quality products or services. Faster order processing, quicker response times to customer inquiries, and fewer errors all contribute to improved customer satisfaction Meaning ● Customer Satisfaction: Ensuring customer delight by consistently meeting and exceeding expectations, fostering loyalty and advocacy. and loyalty. Happy customers are repeat customers, which is vital for SMB growth.

- Scalability and Growth ● As SMBs grow, processes that were manageable at a smaller scale can become bottlenecks. Understanding Process Efficiency Metrics allows SMBs to identify these bottlenecks early and optimize processes to handle increased volume and complexity. This ensures that growth is sustainable and doesn’t lead to operational chaos.

- Competitive Advantage ● In today’s competitive market, efficiency can be a key differentiator. SMBs that operate efficiently can offer better prices, faster service, or higher quality, giving them a competitive edge over less efficient rivals. This is especially crucial in industries with tight margins or intense competition.

Consider a small manufacturing company producing custom furniture. Without tracking Process Efficiency Metrics, they might not realize that their production process has bottlenecks causing delays in delivery. By implementing metrics like production cycle time, defect rate, and resource utilization, they can identify and address these issues.

Perhaps they discover that a particular stage in the manufacturing process is consistently slow, or that there’s a high rate of defects at a specific workstation. Addressing these inefficiencies can lead to faster production times, reduced waste, and happier customers receiving their custom furniture on time and to specification.

Process Efficiency Metrics are the compass and map for SMBs navigating the complexities of their operations, guiding them towards smoother, more profitable journeys.

Basic Process Efficiency Metrics for SMBs

For SMBs just starting to explore Process Efficiency Metrics, it’s best to begin with a few key, easily measurable metrics. These foundational metrics provide a solid starting point for understanding process performance. Here are some essential basic metrics:

Cycle Time

Cycle Time is the total time it takes to complete a process from start to finish. This is a fundamental metric applicable to almost any business process. For a service-based SMB, cycle time might be the time it takes to resolve a customer service Meaning ● Customer service, within the context of SMB growth, involves providing assistance and support to customers before, during, and after a purchase, a vital function for business survival. ticket.

For a product-based SMB, it could be the time to manufacture a product or fulfill an order. Reducing cycle time generally indicates increased efficiency.

Example ● A small marketing agency tracks the cycle time for creating a social media campaign for a client. Initially, it takes an average of 5 days from client brief to campaign launch. By streamlining their internal review process and using project management tools, they reduce the cycle time to 3 days. This faster turnaround time allows them to take on more clients and improve client satisfaction.

Throughput

Throughput measures the amount of work processed within a given timeframe. It indicates the volume of output a process can handle. For example, a restaurant might measure throughput as the number of customers served per hour during peak times.

A call center might measure throughput as the number of calls handled per agent per day. Higher throughput generally signifies better efficiency.

Example ● A small accounting firm tracks the throughput of tax return processing during tax season. Initially, each accountant can process an average of 10 tax returns per week. By implementing better software and standardized processes, they increase throughput to 15 tax returns per week per accountant. This increased throughput allows them to handle more clients without hiring additional staff, boosting profitability.

Error Rate (or Defect Rate)

Error Rate, also known as defect rate, measures the percentage of outputs that are incorrect or defective. This metric is crucial for processes where quality is important. For a manufacturing SMB, it could be the percentage of products that fail quality control.

For a data entry service, it could be the percentage of entries with errors. Lower error rates indicate higher process efficiency and quality.

Example ● A small online retailer tracks the error rate in order fulfillment. Initially, 5% of orders are shipped with errors (wrong items, damaged goods). By improving their picking and packing processes and implementing quality checks, they reduce the error rate to 1%. This reduction in errors leads to fewer returns, lower shipping costs for replacements, and improved customer trust.

Utilization Rate

Utilization Rate measures how effectively resources are being used. This could apply to equipment, staff, or space. For a manufacturing SMB, it might be the percentage of time machines are actively running.

For a consulting firm, it could be the percentage of billable hours for consultants. Higher utilization rates generally indicate better resource efficiency.

Example ● A small printing company tracks the utilization rate of their printing presses. Initially, their presses are only actively printing for 60% of the workday. By improving job scheduling, reducing setup times, and proactively managing maintenance, they increase the utilization rate to 80%. This higher utilization means they can handle more printing jobs with the same equipment, increasing revenue and return on investment.

These basic Process Efficiency Metrics are just the starting point. However, for SMBs beginning their efficiency journey, focusing on these core metrics provides a valuable foundation for understanding and improving their operations. By consistently measuring and analyzing these metrics, SMBs can identify areas for improvement, drive down costs, enhance customer satisfaction, and position themselves for sustainable growth.

Intermediate

Building upon the foundational understanding of Process Efficiency Metrics, we now delve into intermediate-level concepts that offer a more nuanced and strategic approach for SMBs seeking operational excellence. At this stage, simply tracking basic metrics is no longer sufficient. The focus shifts towards deeper analysis, process optimization Meaning ● Enhancing SMB operations for efficiency and growth through systematic process improvements. techniques, and leveraging technology to enhance efficiency gains. For SMBs aiming for sustained growth and a competitive edge, mastering these intermediate concepts is crucial.

Expanding the Metric Toolkit

While basic metrics like cycle time, throughput, and error rate provide a good starting point, a more comprehensive view of process efficiency requires expanding the metric toolkit. Intermediate-level metrics offer deeper insights into process performance and help identify areas for more targeted improvement. Here are some key metrics to consider at this stage:

Customer Satisfaction (CSAT) & Net Promoter Score (NPS) in Process Context

Customer Satisfaction (CSAT) and Net Promoter Score (NPS) are primarily customer experience Meaning ● Customer Experience for SMBs: Holistic, subjective customer perception across all interactions, driving loyalty and growth. metrics, but they are intrinsically linked to process efficiency. Inefficient processes often lead to negative customer experiences. For instance, a slow and cumbersome online ordering process can lead to customer frustration and lower CSAT scores. Similarly, a process that frequently results in errors or delays can negatively impact NPS, reducing customer loyalty and referrals.

By tracking CSAT and NPS in conjunction with process-specific metrics, SMBs can understand how process efficiency directly impacts customer perception. For example, an SMB could measure CSAT specifically for their customer service process, their order fulfillment process, or their product delivery process. A dip in CSAT or NPS related to a specific process can signal underlying inefficiencies that need to be addressed.

Example ● An online clothing boutique starts tracking CSAT scores specifically related to their returns process. Initially, they receive an average CSAT score of 7 out of 10 for returns. Upon investigation, they find that the returns process is slow and complicated, requiring customers to fill out multiple forms and wait several days for approval.

By streamlining the returns process, simplifying the forms, and automating the approval workflow, they improve the CSAT score for returns to 9 out of 10. This not only improves customer satisfaction but also reduces the administrative burden on their staff.

Employee Satisfaction (ESAT) Related to Processes

Just as customer satisfaction is linked to process efficiency, so is Employee Satisfaction (ESAT). Inefficient processes can lead to employee frustration, burnout, and decreased productivity. Repetitive, manual tasks, poorly designed workflows, and lack of clear procedures can all contribute to low ESAT. Conversely, efficient and well-designed processes can empower employees, reduce stress, and increase job satisfaction.

Measuring ESAT in relation to specific processes can provide valuable insights into the human impact of process efficiency. SMBs can conduct employee surveys or feedback sessions to gauge satisfaction with specific workflows, tools, and procedures. For example, employees might express frustration with a clunky CRM system or a manual data entry process. Addressing these process inefficiencies can improve ESAT, reduce employee turnover, and boost overall productivity.

Example ● A small insurance agency notices high employee turnover in their claims processing department. They conduct an ESAT survey and discover that employees are frustrated with the outdated claims processing system, which is slow, prone to errors, and requires significant manual data entry. By investing in a modern, automated claims processing system, they streamline the workflow, reduce manual tasks, and improve data accuracy. As a result, ESAT in the claims department increases, employee turnover decreases, and claims processing time is significantly reduced.

Return on Investment (ROI) of Process Improvement Initiatives

At the intermediate level, process efficiency initiatives should be viewed as investments, not just cost-cutting measures. Therefore, tracking the Return on Investment (ROI) of process improvement Meaning ● Process Improvement, within the scope of Small and Medium-sized Businesses, denotes a systematic and continuous approach to identifying, analyzing, and refining existing business operations to enhance efficiency, reduce costs, and increase overall performance. projects is crucial. ROI measures the financial return generated by an investment relative to its cost. For process improvement, ROI can be calculated by comparing the benefits (e.g., cost savings, revenue increase, productivity gains) to the costs (e.g., implementation expenses, software purchases, training costs).

Calculating ROI for process improvement initiatives helps SMBs prioritize projects that offer the highest potential return. It also provides a quantifiable way to demonstrate the value of efficiency improvements to stakeholders. For example, an SMB might invest in automation software to streamline their inventory management Meaning ● Inventory management, within the context of SMB operations, denotes the systematic approach to sourcing, storing, and selling inventory, both raw materials (if applicable) and finished goods. process. By tracking the ROI, they can assess whether the investment is generating sufficient returns in terms of reduced inventory holding costs, fewer stockouts, and increased order fulfillment speed.

Example ● A small e-commerce business invests $5,000 in implementing an automated inventory management system. Before automation, they experienced frequent stockouts, leading to lost sales and customer dissatisfaction. After implementing the system, they reduce stockouts by 80%, leading to an estimated increase in sales of $15,000 per year. They also reduce inventory holding costs by $2,000 per year due to better inventory control.

The total annual benefit is $17,000. The ROI is calculated as (($17,000 – $5,000) / $5,000) 100% = 240%. This high ROI justifies the investment and demonstrates the significant financial benefits of process automation.

Intermediate Process Efficiency Metrics move beyond basic measurement, focusing on strategic alignment with customer and employee satisfaction, and demonstrating tangible financial returns through ROI analysis.

Process Mapping and Value Stream Mapping

To effectively improve process efficiency, SMBs need to understand their processes in detail. Process Mapping and Value Stream Mapping (VSM) are powerful visual tools that help achieve this understanding. These techniques go beyond simply measuring metrics; they provide a framework for analyzing, visualizing, and optimizing entire processes.

Process Mapping

Process Mapping involves creating a visual representation of a process, outlining the sequence of activities, decision points, inputs, and outputs. It helps to break down complex processes into smaller, more manageable steps, making it easier to identify inefficiencies, bottlenecks, and areas for improvement. Process maps can be created using flowcharts, swim lane diagrams, or other visual formats. The key is to clearly document each step in the process, who is responsible for it, and the inputs and outputs involved.

For SMBs, process mapping Meaning ● Process Mapping, within the realm of Small and Medium-sized Businesses, is a visual depiction of a business process, illustrating the steps involved from initiation to completion. is particularly valuable for:

- Identifying Redundant Steps ● Mapping a process can reveal unnecessary steps or activities that add no value and can be eliminated.

- Pinpointing Bottlenecks ● Visualizing the process flow can highlight stages where work accumulates or slows down, indicating bottlenecks that need to be addressed.

- Improving Communication and Collaboration ● Process maps provide a common understanding of the process for all stakeholders, facilitating better communication and collaboration.

- Standardizing Processes ● Documenting processes through mapping helps to standardize workflows and ensure consistency in execution.

Example ● A small law firm wants to improve the efficiency of their client intake process. They create a process map that outlines all the steps involved, from initial client inquiry to onboarding the client. The map reveals several redundant steps, such as multiple manual data entry points and unnecessary internal approvals. By streamlining the process, eliminating redundancies, and implementing a digital client intake form, they reduce the client intake cycle time by 50% and improve the client experience.

Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a more advanced form of process mapping that focuses specifically on analyzing the flow of materials and information required to deliver a product or service to a customer. VSM goes beyond just mapping the process steps; it also includes information about lead times, cycle times, inventory levels, and waste at each stage. The goal of VSM is to identify and eliminate waste in the entire value stream, from raw materials to finished product or service delivery.

VSM is particularly beneficial for SMBs in manufacturing, logistics, and service industries with complex value chains. It helps to:

- Identify Value-Added and Non-Value-Added Activities ● VSM distinguishes between activities that directly contribute to customer value and those that are wasteful.

- Visualize the Entire Value Stream ● VSM provides a holistic view of the entire process, from supplier to customer, highlighting interdependencies and potential bottlenecks across the value chain.

- Calculate Lead Times and Cycle Times ● VSM quantifies the time spent at each stage of the process, allowing for accurate calculation of overall lead times and cycle times.

- Identify Areas for Waste Reduction ● By visualizing waste (e.g., inventory, delays, defects), VSM helps to target specific areas for improvement and waste elimination.

Example ● A small furniture manufacturer uses VSM to analyze their production process. The VSM reveals significant waste in the form of excessive work-in-progress inventory, long lead times between production stages, and frequent delays due to material shortages. By analyzing the VSM, they identify bottlenecks in their material procurement and production scheduling processes.

They implement just-in-time inventory management, optimize production scheduling, and improve communication with suppliers. As a result, they reduce lead times by 30%, decrease work-in-progress inventory by 50%, and improve overall production efficiency.

Leveraging Technology for Process Efficiency

In today’s digital age, technology plays a pivotal role in enhancing process efficiency for SMBs. Moving beyond manual processes and embracing automation and digital tools is essential for achieving significant efficiency gains. At the intermediate level, SMBs should explore various technological solutions to streamline their processes and improve metric tracking.

Automation Tools

Automation Tools can significantly reduce manual tasks, eliminate errors, and speed up processes. For SMBs, automation can range from simple tasks like automated email responses to more complex workflows like automated invoice processing or order fulfillment. Common automation tools Meaning ● Automation Tools, within the sphere of SMB growth, represent software solutions and digital instruments designed to streamline and automate repetitive business tasks, minimizing manual intervention. include:

- Robotic Process Automation (RPA) ● RPA software can automate repetitive, rule-based tasks performed by humans, such as data entry, data extraction, and report generation.

- Workflow Automation Software ● These tools automate the flow of tasks and information between different stages of a process, ensuring tasks are routed to the right people at the right time.

- CRM and ERP Systems ● Customer Relationship Management (CRM) and Enterprise Resource Planning (ERP) systems integrate various business functions and automate many processes related to sales, marketing, customer service, inventory management, and finance.

Example ● A small accounting firm automates their invoice processing workflow using RPA. Previously, invoices were manually entered into their accounting system, which was time-consuming and prone to errors. By implementing RPA, they automate the data extraction from invoices and the entry into the accounting system. This reduces invoice processing time by 70%, eliminates data entry errors, and frees up staff time for more value-added tasks like client consulting.

Data Analytics and Reporting Tools

To effectively track and analyze Process Efficiency Metrics, SMBs need robust data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. and reporting tools. These tools enable them to collect, visualize, and interpret process data, providing insights into performance trends, bottlenecks, and areas for improvement. Key features of data analytics and reporting tools include:

- Real-Time Dashboards ● Dashboards provide a visual overview of key metrics in real-time, allowing SMBs to monitor process performance continuously.

- Customizable Reports ● Reporting tools enable SMBs to generate customized reports on specific metrics, time periods, or process segments.

- Data Visualization ● Charts, graphs, and other visual representations of data make it easier to identify patterns and trends in process performance.

- Data Integration ● Tools that can integrate data from various sources (e.g., CRM, ERP, automation systems) provide a holistic view of process performance across different business functions.

Example ● A small e-commerce business implements a data analytics platform to track their order fulfillment process. The platform integrates data from their e-commerce platform, warehouse management system, and shipping provider. Real-time dashboards display key metrics like order processing time, shipping time, error rate, and customer satisfaction scores.

By analyzing the data, they identify bottlenecks in their picking and packing process during peak hours. They then optimize their warehouse layout and staffing levels, resulting in a 20% reduction in order processing time and improved customer satisfaction.

By embracing these intermediate-level strategies ● expanding the metric toolkit, utilizing process mapping techniques, and leveraging technology ● SMBs can move beyond basic efficiency improvements and achieve significant operational gains. This deeper level of process understanding and optimization is crucial for sustained growth and competitiveness in the dynamic SMB landscape.

Advanced

At the advanced level, the understanding and application of Process Efficiency Metrics transcend mere operational optimization. It evolves into a strategic business philosophy, deeply intertwined with innovation, adaptability, and long-term sustainability for SMBs. Moving beyond incremental improvements, advanced process efficiency focuses on fundamentally rethinking processes, leveraging predictive analytics, and navigating the complex interplay between efficiency and organizational agility. This section will redefine Process Efficiency Metrics from an expert perspective, exploring its multifaceted dimensions and strategic implications for SMBs operating in an increasingly dynamic and competitive global landscape.

Redefining Process Efficiency Metrics ● Agility and Innovation Imperative

Traditionally, Process Efficiency Metrics have been narrowly defined around cost reduction, speed, and error minimization. While these remain important, an advanced perspective recognizes that in today’s SMB environment, efficiency must also encompass Agility and Innovation. A hyper-focus on narrow efficiency metrics, without considering these broader strategic imperatives, can inadvertently stifle creativity, adaptability, and long-term growth. Therefore, we redefine Process Efficiency Metrics at the advanced level as:

Process Efficiency Metrics (Advanced Definition) ● A holistic framework for evaluating and optimizing business processes, not solely for cost reduction and speed, but also to enhance organizational agility, foster innovation, and ensure long-term sustainability, while maintaining a customer-centric and employee-empowered approach.

This redefined definition shifts the emphasis from purely operational metrics to a more strategic and nuanced understanding of efficiency. It acknowledges that true efficiency in the modern SMB context is not just about doing things faster and cheaper, but also about being adaptable to change, fostering a culture of innovation, and ensuring the long-term health of the organization.

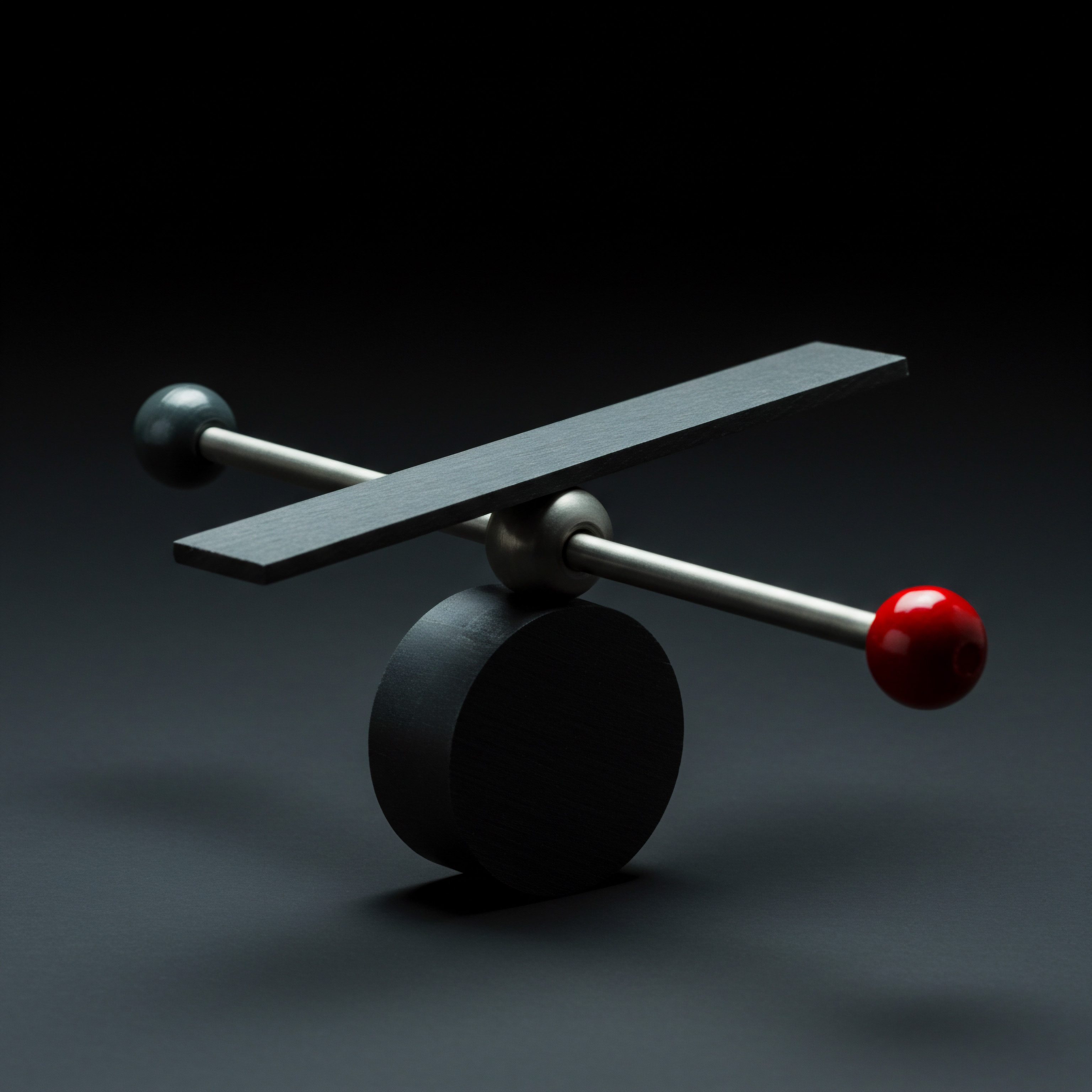

The Paradox of Efficiency ● Balancing Optimization with Flexibility

A critical aspect of advanced Process Efficiency Metrics is understanding the potential paradox of efficiency. While efficiency is undoubtedly beneficial, an excessive and rigid pursuit of optimization can lead to inflexibility and hinder innovation. Processes that are hyper-optimized for current conditions may become brittle and unable to adapt to changing market demands, technological disruptions, or unforeseen circumstances. This paradox highlights the need for a balanced approach, where efficiency is pursued in conjunction with flexibility and adaptability.

The Risks of Hyper-Optimization

Over-optimization, driven by a narrow focus on traditional efficiency metrics, can lead to several risks for SMBs:

- Reduced Adaptability ● Highly optimized processes can become rigid and difficult to change, making it challenging for SMBs to respond quickly to market shifts or new opportunities.

- Stifled Innovation ● A relentless focus on efficiency can discourage experimentation and risk-taking, which are essential for innovation. Processes designed for maximum efficiency may not allow for the slack and experimentation needed for creative problem-solving and new idea generation.

- Decreased Employee Empowerment ● Overly prescriptive and tightly controlled processes can stifle employee initiative and autonomy, leading to decreased job satisfaction and reduced employee engagement in process improvement.

- Vulnerability to Disruptions ● Hyper-optimized supply chains and processes can become vulnerable to disruptions, as they often lack redundancy and flexibility to cope with unexpected events (e.g., natural disasters, geopolitical instability, pandemics).

Example ● A small manufacturing SMB, focused solely on minimizing production costs, implements a highly optimized just-in-time inventory system and lean manufacturing processes. While this initially reduces costs and improves efficiency, it also makes them highly vulnerable to supply chain disruptions. When a key supplier faces unexpected production delays due to a natural disaster, the SMB’s production line grinds to a halt, leading to significant losses and customer dissatisfaction. This highlights the risk of hyper-optimization without considering resilience and flexibility.

Building Agile and Resilient Processes

To mitigate the risks of hyper-optimization, SMBs need to design processes that are both efficient and agile. This involves incorporating flexibility and redundancy into process design, fostering a culture of continuous improvement Meaning ● Ongoing, incremental improvements focused on agility and value for SMB success. and experimentation, and empowering employees to adapt and innovate. Strategies for building agile and resilient processes include:

- Modular Process Design ● Breaking down complex processes into smaller, modular units allows for greater flexibility and easier adaptation. Modules can be reconfigured or replaced without disrupting the entire process.

- Redundancy and Backup Systems ● Incorporating backup systems and redundancies in critical processes ensures business continuity in case of disruptions. This could include having multiple suppliers, backup equipment, or alternative workflows.

- Cross-Training and Skill Diversification ● Training employees in multiple skills and cross-training them across different process areas increases organizational flexibility and resilience. Employees can be redeployed to different tasks or roles as needed.

- Continuous Improvement Culture ● Fostering a culture of continuous improvement encourages ongoing process evaluation, experimentation, and adaptation. Regularly reviewing and refining processes ensures they remain efficient and relevant in a changing environment.

- Embracing Technology for Flexibility ● Leveraging cloud-based technologies, flexible automation solutions, and data analytics tools can enhance process agility. Cloud platforms enable scalability and remote access, while flexible automation can be easily reconfigured for different tasks. Data analytics provides insights into process performance and areas for adaptation.

Example ● A small software development SMB adopts agile development methodologies and cloud-based infrastructure. Agile development allows them to iterate quickly, adapt to changing customer requirements, and incorporate feedback continuously. Cloud infrastructure provides scalability and flexibility to handle fluctuating workloads and adapt to new technologies. This combination of agile processes and flexible technology enables them to be highly responsive to market demands and maintain a competitive edge in the rapidly evolving software industry.

Advanced Process Efficiency Metrics recognizes the paradox of efficiency, advocating for a balanced approach that prioritizes both optimization and organizational agility Meaning ● Organizational Agility: SMB's capacity to swiftly adapt & leverage change for growth through flexible processes & strategic automation. to ensure long-term SMB success.

Predictive Analytics and Proactive Process Optimization

At the advanced level, Process Efficiency Metrics are not just about measuring past performance; they are also about predicting future performance and proactively optimizing processes. Predictive Analytics leverages data mining, machine learning, and statistical modeling to forecast future process outcomes and identify potential issues before they occur. This proactive approach to process optimization enables SMBs to anticipate challenges, prevent inefficiencies, and continuously improve performance.

Leveraging Data for Predictive Insights

To effectively utilize predictive analytics Meaning ● Strategic foresight through data for SMB success. for process optimization, SMBs need to collect and analyze relevant process data. This data can come from various sources, including:

- Process Monitoring Systems ● Sensors, IoT devices, and automated data collection systems can provide real-time data on process parameters, equipment performance, and environmental conditions.

- Transaction Data ● CRM, ERP, and other business systems capture transactional data related to sales, orders, inventory, customer interactions, and financial transactions.

- Operational Data ● Data from manufacturing execution systems (MES), warehouse management systems (WMS), and other operational systems provide insights into production processes, logistics, and supply chain activities.

- External Data Sources ● Market data, economic indicators, weather forecasts, and social media trends can provide contextual information that influences process performance.

By integrating and analyzing this data, SMBs can develop predictive models Meaning ● Predictive Models, in the context of SMB growth, refer to analytical tools that forecast future outcomes based on historical data, enabling informed decision-making. that forecast future process outcomes, such as:

- Demand Forecasting ● Predicting future demand for products or services allows for proactive inventory management, production planning, and resource allocation.

- Equipment Failure Prediction ● Predictive maintenance models can forecast equipment failures, enabling proactive maintenance scheduling and minimizing downtime.

- Process Bottleneck Prediction ● Analyzing process data can identify potential bottlenecks before they occur, allowing for proactive adjustments to workflows and resource allocation.

- Quality Prediction ● Predictive quality models can forecast product or service quality based on process parameters, enabling proactive quality control measures and defect prevention.

Example ● A small food processing SMB implements predictive analytics to optimize their production process. They collect data from sensors on their production line, including temperature, pressure, humidity, and machine performance. By analyzing this data using machine learning algorithms, they develop a predictive model that forecasts potential equipment failures and quality issues.

The model alerts them to impending equipment malfunctions and predicts potential quality deviations based on process parameters. This allows them to proactively schedule maintenance, adjust process settings, and prevent production downtime and quality defects, resulting in significant cost savings and improved product quality.

Proactive Process Optimization Strategies

Predictive insights enable SMBs to move from reactive to proactive process optimization. Instead of reacting to problems after they occur, they can anticipate issues and take preventive measures. Proactive process optimization strategies include:

- Predictive Maintenance ● Scheduling maintenance based on predicted equipment failure rather than fixed intervals minimizes downtime and extends equipment lifespan.

- Dynamic Resource Allocation ● Adjusting resource allocation Meaning ● Strategic allocation of SMB assets for optimal growth and efficiency. (e.g., staffing, equipment, materials) based on predicted demand fluctuations ensures optimal resource utilization and prevents bottlenecks.

- Proactive Quality Control ● Implementing quality control measures based on predicted quality deviations prevents defects and reduces waste.

- Adaptive Process Control ● Dynamically adjusting process parameters based on real-time data and predictive models ensures optimal process performance under varying conditions.

- Scenario Planning and Simulation ● Using predictive models to simulate different scenarios and evaluate the impact of potential changes allows for proactive process design and optimization.

Example ● A small logistics SMB uses predictive analytics to optimize their delivery routes and resource allocation. They integrate data from GPS tracking systems, traffic data, weather forecasts, and customer order data. Using predictive models, they forecast delivery times, traffic congestion, and potential delays.

Based on these predictions, they dynamically optimize delivery routes, adjust driver schedules, and proactively communicate with customers about potential delays. This proactive approach reduces delivery times, minimizes fuel consumption, improves customer satisfaction, and enhances overall logistics efficiency.

Ethical and Human-Centric Considerations in Process Efficiency

While advanced Process Efficiency Metrics drive significant operational improvements, it is crucial to consider the ethical and human-centric implications of these strategies, particularly in the context of automation and data-driven decision-making. An advanced approach to process efficiency must not only focus on maximizing output and minimizing costs but also on ensuring ethical practices, employee well-being, and positive societal impact.

Ethical Considerations of Automation

Automation, while enhancing efficiency, raises ethical concerns, particularly regarding job displacement Meaning ● Strategic workforce recalibration in SMBs due to tech, markets, for growth & agility. and workforce impact. SMBs need to consider the ethical implications of automation and implement responsible automation strategies that mitigate negative social consequences. Ethical automation principles include:

- Transparency and Explainability ● Automation systems and algorithms should be transparent and explainable, particularly when making decisions that impact employees or customers.

- Fairness and Bias Mitigation ● Automation algorithms should be designed to be fair and unbiased, avoiding discriminatory outcomes based on protected characteristics.

- Job Displacement Mitigation ● SMBs should proactively address potential job displacement due to automation by providing retraining opportunities, creating new roles, and supporting affected employees.

- Human Oversight and Control ● Critical processes and decisions should retain human oversight and control, even with automation, to ensure ethical considerations are taken into account.

- Data Privacy and Security ● Automation systems often rely on data collection and processing, making data privacy and security paramount. SMBs must implement robust data protection measures and comply with relevant privacy regulations.

Example ● A small customer service SMB implements AI-powered chatbots to automate routine customer inquiries. While this improves efficiency and reduces response times, they are mindful of the ethical implications. They ensure that chatbots are transparently identified as AI, provide clear options for human agent interaction, and are designed to be unbiased in their responses. They also invest in retraining customer service agents to handle more complex inquiries and provide higher-value services, mitigating potential job displacement and enhancing employee skills.

Human-Centric Process Design

Advanced Process Efficiency Metrics should not come at the expense of employee well-being and customer experience. Human-centric process design prioritizes the needs and experiences of both employees and customers, ensuring that efficiency improvements enhance, rather than detract from, the human element of business. Principles of human-centric process design include:

- Employee Empowerment and Autonomy ● Designing processes that empower employees, provide autonomy, and encourage initiative enhances job satisfaction and engagement, even within efficient workflows.

- Customer Journey Mapping and Empathy ● Understanding the customer journey from the customer’s perspective and designing processes with empathy ensures a positive and seamless customer experience.

- Usability and Accessibility ● Process interfaces, tools, and systems should be designed for usability and accessibility, ensuring they are easy to use and inclusive for all employees and customers.

- Work-Life Balance and Well-Being ● Process efficiency initiatives should consider the impact on employee work-life balance and well-being, avoiding burnout and promoting a healthy work environment.

- Feedback Loops and Continuous Improvement ● Establishing feedback loops from both employees and customers allows for continuous process improvement and ensures that human needs and experiences are considered in ongoing optimization efforts.

Example ● A small healthcare clinic implements process improvements to streamline patient appointments and reduce wait times. They focus on human-centric design by involving both staff and patients in the process redesign. They optimize appointment scheduling workflows, implement online self-scheduling options for patients, and redesign the waiting area to be more comfortable and welcoming.

They also empower staff to make decisions and adapt processes to individual patient needs. This human-centric approach not only improves efficiency and reduces wait times but also enhances patient satisfaction and employee morale.

In conclusion, advanced Process Efficiency Metrics for SMBs is a multifaceted and strategic discipline that goes beyond traditional notions of cost and speed optimization. It encompasses agility, innovation, predictive analytics, ethical considerations, and a human-centric approach. By embracing this holistic and advanced perspective, SMBs can achieve sustainable operational excellence, foster a culture of innovation, and thrive in the complexities of the modern business landscape.