Fundamentals

For Small to Medium-sized Businesses (SMBs), the concept of Supply Chain Resilience might seem like a complex, enterprise-level concern. However, in today’s volatile global marketplace, it’s more critical than ever, regardless of size. At its most basic, Supply Chain Resilience is the ability of your business’s supply network to withstand unexpected disruptions and bounce back quickly.

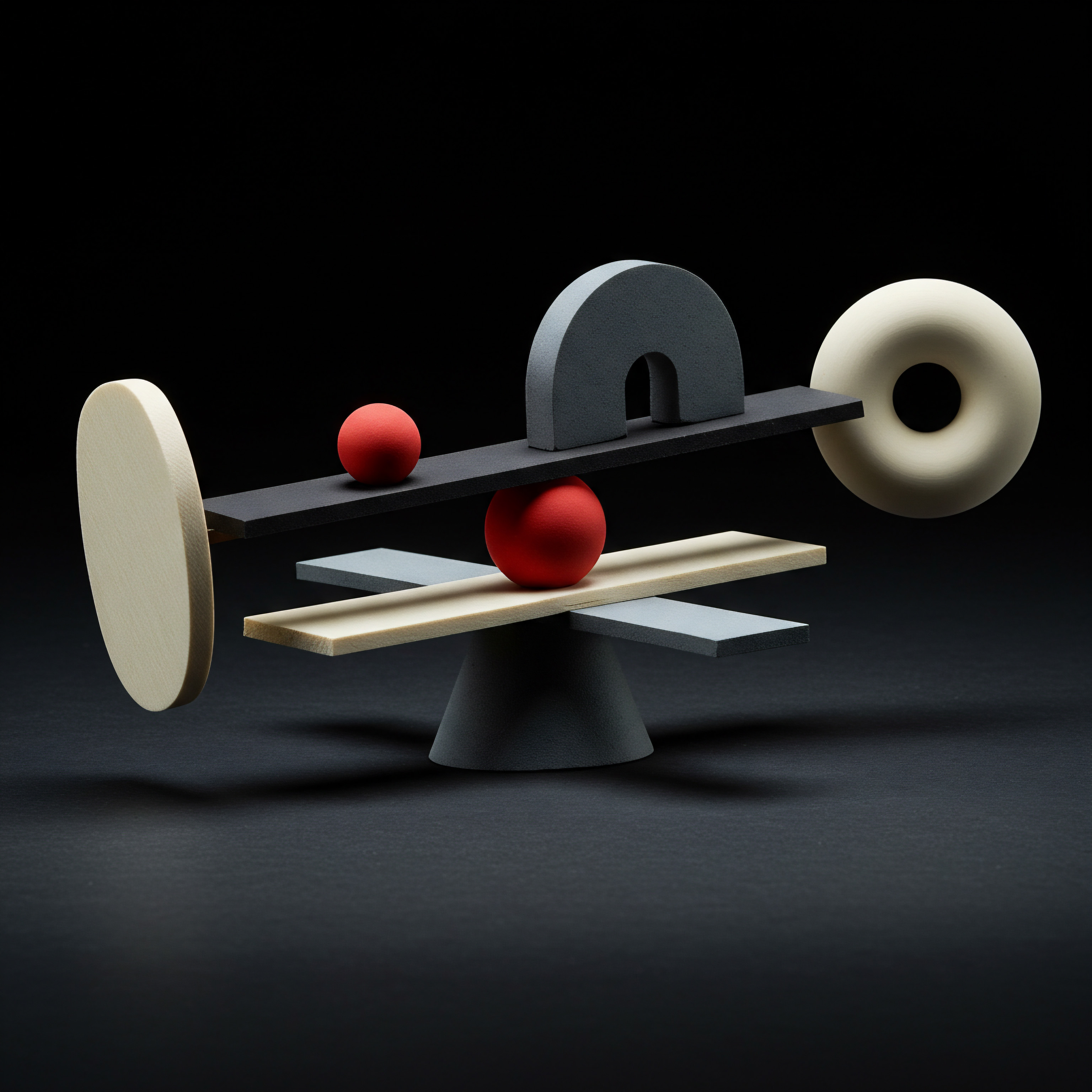

Think of it like a flexible tree in a storm ● it bends and sways but doesn’t break. For an SMB, this could mean ensuring you can still get the materials you need to produce your goods, or that you can deliver your services even when unforeseen events occur.

Supply chain resilience for SMBs is about proactive preparation and agile response to disruptions, ensuring business continuity Meaning ● Ensuring SMB operational survival and growth through proactive planning and resilience building. and growth.

Understanding the Core Components

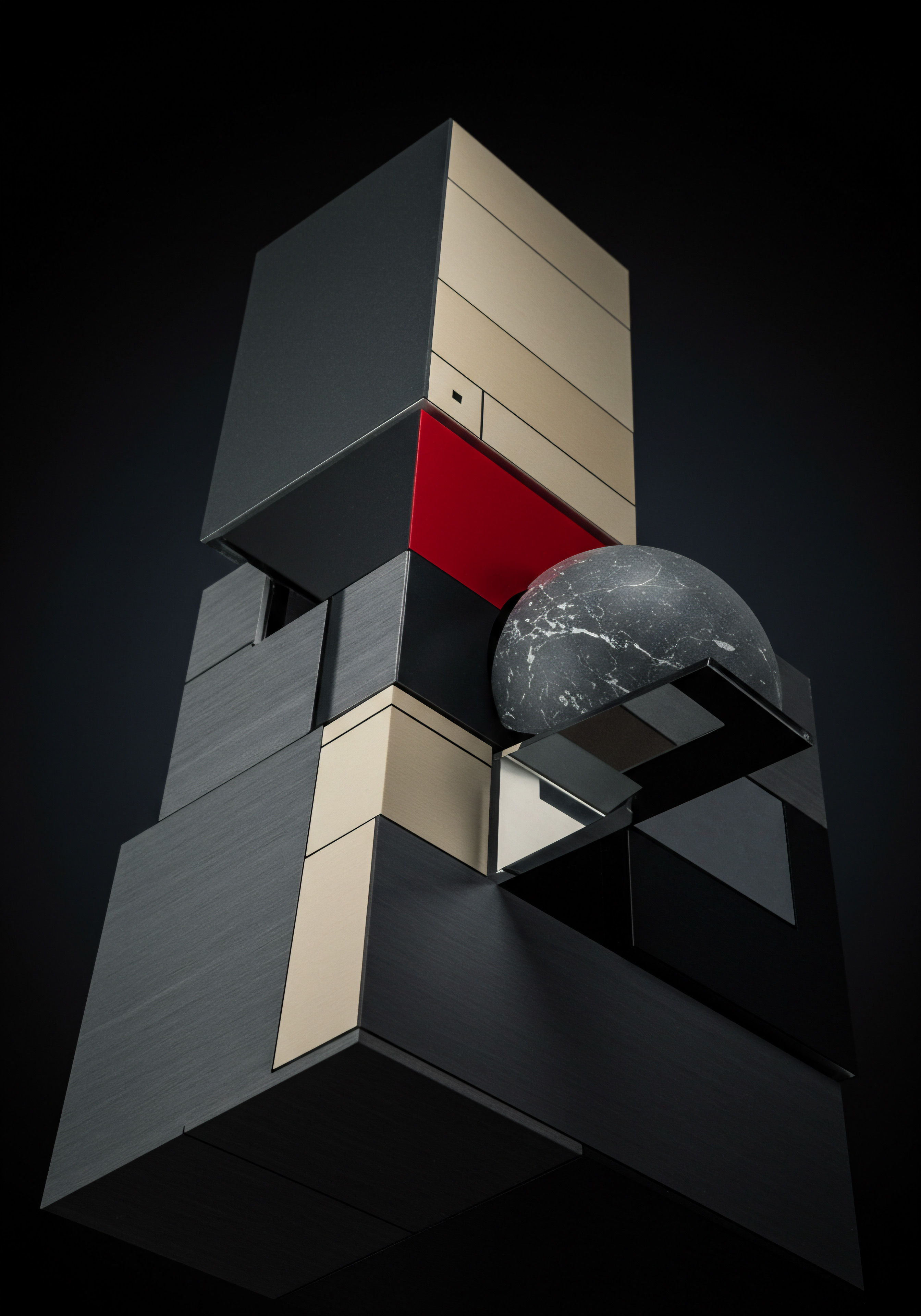

To grasp Predictive Supply Chain Resilience, we first need to break down the individual parts. Let’s start with ‘supply chain’. For an SMB, the Supply Chain is the interconnected network of all the steps involved in getting your product or service to your customer. This includes sourcing raw materials, manufacturing, warehousing, transportation, and finally, delivery to the end-user.

It’s a chain, because each step is linked to the next. Now, ‘resilience’, as we touched upon, is the capacity to recover quickly from difficulties or toughness. In a business context, this means being able to adapt and overcome challenges without significant negative impact.

The ‘predictive’ aspect adds a crucial layer. Predictive Supply Chain Resilience isn’t just about reacting to problems; it’s about anticipating them. It involves using data, analytics, and foresight to identify potential risks before they materialize. This proactive approach allows SMBs to take preventative measures, minimizing the impact of disruptions and even turning potential threats into opportunities.

For instance, imagine a local bakery (an SMB) that relies on imported flour. A predictive approach would involve monitoring global weather patterns and geopolitical events that could affect wheat harvests and shipping routes. By anticipating potential flour shortages or price increases, the bakery can proactively secure alternative suppliers or adjust their pricing strategy.

Why Resilience Matters for SMBs

SMBs often operate with leaner resources and tighter margins than larger corporations. This makes them particularly vulnerable to supply chain disruptions. A single supplier going bankrupt, a sudden spike in shipping costs, or a localized natural disaster can have a devastating impact on an SMB’s operations and profitability. Consider a small clothing boutique that sources its garments from a single factory overseas.

If that factory faces unexpected closures due to a pandemic or political instability, the boutique could face empty shelves, lost sales, and damaged customer relationships. Supply Chain Resilience is not just a nice-to-have for SMBs; it’s a survival imperative in today’s unpredictable world.

Here’s why focusing on resilience is paramount for SMB growth:

- Business Continuity ● Resilience ensures that your business can continue operating, even when disruptions occur. This minimizes downtime, protects revenue streams, and maintains customer trust. For an SMB, consistent operations are vital for building a stable customer base and reputation.

- Cost Reduction ● While investing in resilience might seem like an upfront cost, it can lead to significant long-term cost savings. By proactively mitigating risks, SMBs can avoid costly disruptions, emergency sourcing, and expedited shipping fees. For example, diversifying suppliers might slightly increase administrative overhead, but it can prevent massive losses if a primary supplier fails.

- Competitive Advantage ● In a market where disruptions are increasingly common, a resilient supply chain can be a significant differentiator. SMBs that can consistently deliver on their promises, even when others struggle, gain a competitive edge. Customers value reliability, and a resilient supply chain builds that reliability into your brand.

Common Supply Chain Risks for SMBs

Before we delve into predictive strategies, it’s essential to understand the types of risks SMBs commonly face in their supply chains. These risks can be broadly categorized:

- Supplier Dependence ● Many SMBs rely on a limited number of suppliers, sometimes even a single source, to simplify operations and potentially negotiate better prices. However, this creates significant vulnerability. If that supplier faces issues ● financial distress, operational problems, or natural disasters ● the SMB’s entire supply chain is at risk. Supplier Diversification is a key resilience strategy.

- Transportation Bottlenecks ● SMBs often rely on efficient transportation networks to move goods. Disruptions to these networks ● port congestion, fuel price volatility, geopolitical instability affecting shipping routes ● can lead to delays, increased costs, and inventory shortages. Transportation Planning and alternative routing are crucial.

- Demand Volatility ● Fluctuations in customer demand are inherent in business, but extreme volatility, especially unexpected surges or sudden drops, can strain an SMB’s supply chain. Inability to meet sudden demand can lead to lost sales and customer dissatisfaction, while overstocking during demand drops can tie up capital and lead to inventory obsolescence. Demand Forecasting and flexible production are vital.

- Geopolitical and Economic Instability ● Global events ● trade wars, political unrest, economic recessions ● can have ripple effects on SMB supply chains, particularly those with international suppliers or customers. Tariffs, currency fluctuations, and economic downturns can impact costs, demand, and overall supply chain stability. Economic Monitoring and scenario planning Meaning ● Scenario Planning, for Small and Medium-sized Businesses (SMBs), involves formulating plausible alternative futures to inform strategic decision-making. are essential.

- Natural Disasters and Pandemics ● Events like hurricanes, earthquakes, floods, and global pandemics can cause widespread disruptions to supply chains, affecting production, transportation, and demand. These events highlight the need for robust contingency plans and geographically diverse supply networks. Disaster Preparedness and risk mapping are crucial.

- Cybersecurity Threats ● Increasingly, supply chains are interconnected digitally. This digital integration, while offering efficiency gains, also exposes SMBs to cybersecurity risks. Data breaches, ransomware attacks, and disruptions to digital infrastructure can cripple supply chain operations. Cybersecurity Measures and data protection are paramount.

Understanding these common risks is the first step towards building a Predictive Supply Chain Resilience strategy. For an SMB, it’s not about eliminating all risks (which is impossible), but about understanding, mitigating, and preparing to respond effectively when disruptions inevitably occur.

Initial Steps for SMBs to Enhance Resilience

Building a resilient supply chain doesn’t require massive investments or complex technologies, especially for SMBs starting out. Here are some practical, foundational steps SMBs can take immediately:

- Risk Assessment ● Begin by identifying potential vulnerabilities in your current supply chain. Ask questions like ● Who are our critical suppliers? What are the potential risks associated with each supplier? What transportation routes do we rely on? Where are our biggest points of vulnerability? This Risk Mapping exercise is the cornerstone of resilience.

- Supplier Diversification (Gradual) ● While completely overhauling your supplier network overnight is impractical, start exploring alternative suppliers for critical inputs. Even having a backup supplier identified and vetted can significantly reduce risk. Phased Diversification is a realistic approach for SMBs.

- Inventory Management Review ● Analyze your current inventory levels. Are you holding too much inventory, tying up capital, or too little, risking stockouts? Consider implementing better inventory management Meaning ● Inventory management, within the context of SMB operations, denotes the systematic approach to sourcing, storing, and selling inventory, both raw materials (if applicable) and finished goods. techniques, like Just-in-Case (JIC) inventory for critical items, balancing cost and resilience. Optimized Inventory is a key resilience tactic.

- Communication and Transparency ● Establish clear communication channels with your suppliers, customers, and logistics partners. Regular communication helps identify potential issues early and allows for coordinated responses. Open Communication builds trust and facilitates faster problem-solving.

- Contingency Planning Basics ● Develop basic contingency plans for common disruptions. What will you do if a key supplier has a problem? What are your alternative transportation options if a route is blocked? Even simple plans can make a big difference in a crisis. Preparedness Planning is essential, even in basic form.

These fundamental steps lay the groundwork for a more resilient supply chain. As SMBs grow and mature, they can then build upon these foundations with more sophisticated predictive strategies and technologies, which we will explore in the intermediate and advanced sections.

For SMBs, starting with simple risk assessments, supplier diversification, and clear communication is the foundation of building supply chain resilience.

Intermediate

Building upon the foundational understanding of Supply Chain Resilience, we now move into the intermediate level, focusing on how SMBs can proactively enhance their resilience through more sophisticated strategies and tools. At this stage, it’s about moving beyond reactive measures and implementing systems that not only respond to disruptions but also anticipate and mitigate them before they significantly impact operations. This involves leveraging data, technology, and strategic partnerships Meaning ● Strategic partnerships for SMBs are collaborative alliances designed to achieve mutual growth and strategic advantage. to create a more robust and adaptable supply chain.

Intermediate supply chain resilience Meaning ● Supply Chain Resilience for SMBs: Building adaptive capabilities to withstand disruptions and ensure business continuity. for SMBs involves leveraging data, technology, and strategic partnerships to proactively mitigate risks and enhance adaptability.

Deep Dive into Predictive Capabilities

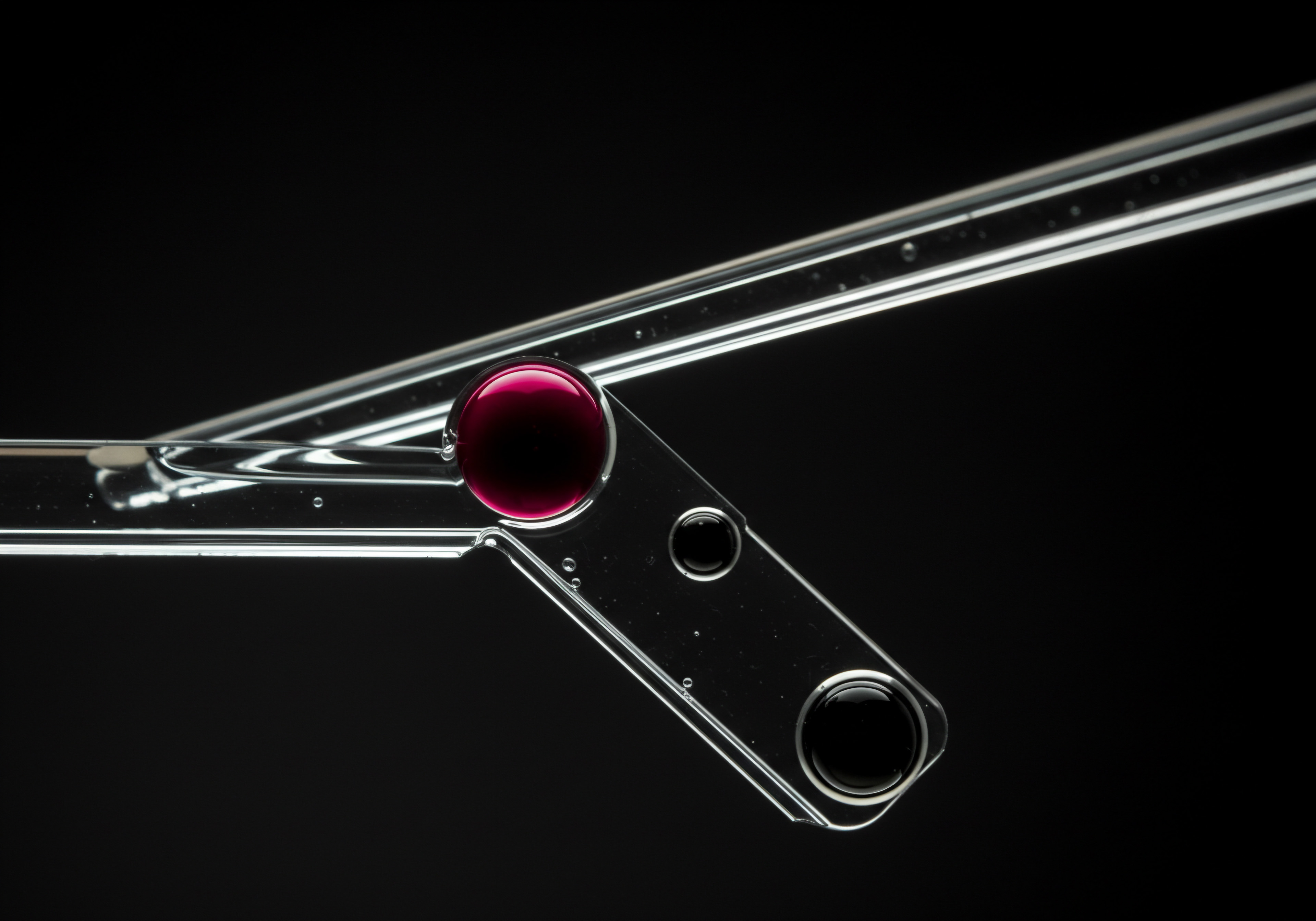

The ‘predictive’ aspect of Predictive Supply Chain Resilience becomes more pronounced at this intermediate level. It’s about transitioning from simply reacting to past disruptions to actively forecasting and preparing for future challenges. This shift requires embracing data-driven decision-making and incorporating tools that provide visibility and foresight into the supply chain.

For SMBs, this doesn’t necessarily mean investing in expensive, enterprise-grade software immediately. It can start with leveraging readily available data sources and affordable technologies to gain predictive insights.

Data Sources for Predictive Insights

SMBs often underestimate the wealth of data they already possess or can readily access. Here are some key data sources that can be leveraged for predictive supply chain Meaning ● Anticipating future supply chain needs using data and AI for SMB efficiency and resilience. resilience:

- Historical Sales Data ● Analyzing past sales trends, seasonality, and promotional impacts provides valuable insights into demand patterns. This data can be used to forecast future demand and anticipate potential surges or dips, allowing for proactive inventory adjustments and production planning. Demand Forecasting starts with historical sales analysis.

- Supplier Performance Data ● Tracking supplier lead times, on-time delivery rates, quality metrics, and pricing fluctuations provides critical information about supplier reliability and potential risks. Identifying suppliers with consistent delays or quality issues allows SMBs to proactively seek alternatives or implement mitigation strategies. Supplier Monitoring is essential for risk prediction.

- Logistics Data ● Monitoring transportation times, shipping costs, and potential delays across different routes and carriers helps identify bottlenecks and vulnerabilities in the logistics network. This data can inform decisions about route optimization, carrier diversification, and inventory positioning. Logistics Analytics enhances predictive visibility.

- External Data Sources ● Leveraging publicly available data, such as weather forecasts, economic indicators, industry reports, and news feeds, provides valuable context and early warning signals for potential disruptions. For example, monitoring weather patterns can help anticipate transportation delays, while economic forecasts can inform demand planning. External Data Integration expands predictive scope.

Technology Tools for Prediction

Several affordable and accessible technology tools can empower SMBs to enhance their predictive capabilities without breaking the bank:

- Spreadsheet Software (Advanced) ● While basic spreadsheets are useful for data entry, advanced features like pivot tables, statistical functions, and charting tools can be used for data analysis and basic forecasting. SMBs can start by using spreadsheets to analyze historical sales data, track supplier performance, and create simple demand forecasts. Spreadsheet Analytics are a cost-effective starting point.

- Cloud-Based Inventory Management Systems ● Many cloud-based inventory management systems offer built-in analytics and reporting features that provide real-time visibility into inventory levels, sales trends, and supplier performance. These systems often include basic forecasting capabilities and can integrate with e-commerce platforms and accounting software. Cloud Inventory Systems offer accessible analytics.

- Supply Chain Visibility Platforms (SMB-Focused) ● Emerging platforms specifically designed for SMBs offer affordable supply chain visibility Meaning ● Supply Chain Visibility for SMBs means having a clear, real-time view of your operations to improve efficiency, resilience, and customer satisfaction. and tracking capabilities. These platforms often leverage IoT (Internet of Things) sensors and GPS tracking to provide real-time insights into shipment locations, inventory movements, and potential delays. SMB Visibility Platforms bridge the technology gap.

- Predictive Analytics Software (Entry-Level) ● As SMBs mature, they can explore entry-level predictive analytics software. These tools, often cloud-based and subscription-based, offer more advanced forecasting algorithms, scenario planning capabilities, and risk assessment Meaning ● In the realm of Small and Medium-sized Businesses (SMBs), Risk Assessment denotes a systematic process for identifying, analyzing, and evaluating potential threats to achieving strategic goals in areas like growth initiatives, automation adoption, and technology implementation. features. They can integrate with existing data sources and provide more sophisticated insights. Entry-Level Analytics Software enables advanced prediction.

Developing a Proactive Risk Mitigation Strategy

Predictive capabilities are only valuable if they are translated into proactive risk mitigation Meaning ● Proactive Risk Mitigation: Anticipating and preemptively managing SMB risks to ensure stability, growth, and competitive advantage. strategies. At the intermediate level, SMBs should develop more structured and formalized approaches to mitigating identified supply chain risks. This involves creating contingency plans, diversifying risk, and building flexibility into operations.

Enhanced Contingency Planning

Building upon the basic contingency plans from the fundamental level, intermediate-level SMBs should develop more detailed and scenario-based plans. This involves:

- Scenario Planning ● Instead of just having generic contingency plans, develop specific plans for different types of disruptions. For example, have separate plans for supplier failures, transportation disruptions, demand surges, and natural disasters. Scenario-Specific Plans improve preparedness.

- Redundancy and Backup Systems ● Identify critical points of failure in your supply chain and build in redundancy. This could involve having backup suppliers, alternative transportation routes, or secondary warehousing locations. Redundancy Layers enhance resilience depth.

- Business Continuity Plans (BCP) ● Develop a comprehensive Business Continuity Plan that outlines procedures for responding to various disruptions and ensuring business operations can continue. This plan should include communication protocols, roles and responsibilities, and step-by-step recovery procedures. Formalized BCP provides structured response.

- Regular Plan Testing and Drills ● Contingency plans are only effective if they are regularly tested and updated. Conduct periodic drills and simulations to identify weaknesses in the plans and ensure that employees are familiar with their roles and responsibilities in a crisis. Plan Testing ensures practical effectiveness.

Strategic Diversification and Flexibility

Beyond contingency planning, strategic diversification Meaning ● Strategic Diversification: SMB expansion beyond core offerings for risk mitigation, growth, and long-term resilience in volatile markets. and operational flexibility Meaning ● Operational flexibility for SMBs is the ability to adapt operations to market changes for resilience and growth. are crucial intermediate-level resilience strategies:

- Multi-Sourcing Strategy ● Move beyond simply having backup suppliers to actively implementing a multi-sourcing strategy. This involves sourcing critical inputs from multiple suppliers, potentially in different geographic locations. This reduces dependence on any single supplier and mitigates the risk of widespread disruptions. Active Multi-Sourcing distributes risk.

- Flexible Manufacturing and Operations ● Design operational processes to be more flexible and adaptable. This could involve implementing modular production systems, cross-training employees, and investing in equipment that can be quickly reconfigured to produce different products or adapt to changing demand. Operational Flexibility enables agile response.

- Nearshoring and Regionalization ● For SMBs with international supply chains, consider nearshoring or regionalization strategies. This involves shifting sourcing or manufacturing closer to home, reducing reliance on long-distance supply chains and mitigating risks associated with global disruptions. Geographic Diversification reduces global risk.

- Postponement Strategy ● Where feasible, implement a postponement strategy. This involves delaying final product customization or assembly until closer to the point of sale. This reduces the risk of holding obsolete inventory and allows for greater responsiveness to changing customer demands. Postponement increases demand responsiveness.

Building Collaborative Resilience Networks

At the intermediate level, SMBs should also recognize the importance of collaboration in building supply chain resilience. No SMB operates in isolation, and building strong relationships with suppliers, customers, and even competitors can enhance collective resilience.

Supplier Relationship Management (SRM)

Moving beyond transactional relationships with suppliers to strategic partnerships is crucial for resilience. This involves:

- Supplier Collaboration ● Share information and forecasts with key suppliers to improve their planning and responsiveness. Collaborative forecasting and planning reduces bullwhip effect and improves supply chain efficiency. Collaborative Planning strengthens supplier links.

- Supplier Development Programs ● Invest in supplier development programs to improve the capabilities and resilience of your key suppliers. This could involve providing training, technical assistance, or financial support to help suppliers enhance their operations and risk management practices. Supplier Development builds shared resilience.

- Joint Risk Assessments ● Conduct joint risk assessments with key suppliers to identify potential vulnerabilities and develop coordinated mitigation strategies. Collaborative risk assessment fosters shared responsibility for resilience. Joint Risk Assessment creates mutual awareness.

- Long-Term Contracts and Partnerships ● Move towards longer-term contracts and strategic partnerships with reliable suppliers. These partnerships foster trust, commitment, and a shared interest in building resilient supply chains. Strategic Partnerships ensure long-term resilience.

Industry and Peer Networks

SMBs can also benefit from participating in industry associations, peer networks, and collaborative initiatives to enhance collective resilience:

- Industry Associations ● Engage with industry associations to access resources, best practices, and collective intelligence on supply chain resilience. Associations often provide training, workshops, and forums for sharing knowledge and experiences. Industry Networks provide shared knowledge.

- Peer-To-Peer Learning ● Connect with other SMBs in your industry or region to share experiences, challenges, and best practices related to supply chain resilience. Peer-to-peer learning can provide valuable insights and support. Peer Networks offer practical support.

- Collaborative Platforms ● Explore collaborative platforms or consortia that facilitate information sharing and joint initiatives among multiple organizations in a supply chain ecosystem. These platforms can enhance visibility, coordination, and collective response to disruptions. Collaborative Platforms enhance ecosystem resilience.

By implementing these intermediate-level strategies, SMBs can significantly enhance their Predictive Supply Chain Resilience. It’s about moving from reactive to proactive, leveraging data and technology, and building collaborative networks to create a more robust and adaptable supply chain capable of weathering future disruptions and supporting sustainable growth.

Intermediate resilience building involves structured risk mitigation, strategic diversification, and fostering collaborative networks for enhanced adaptability and foresight.

Advanced

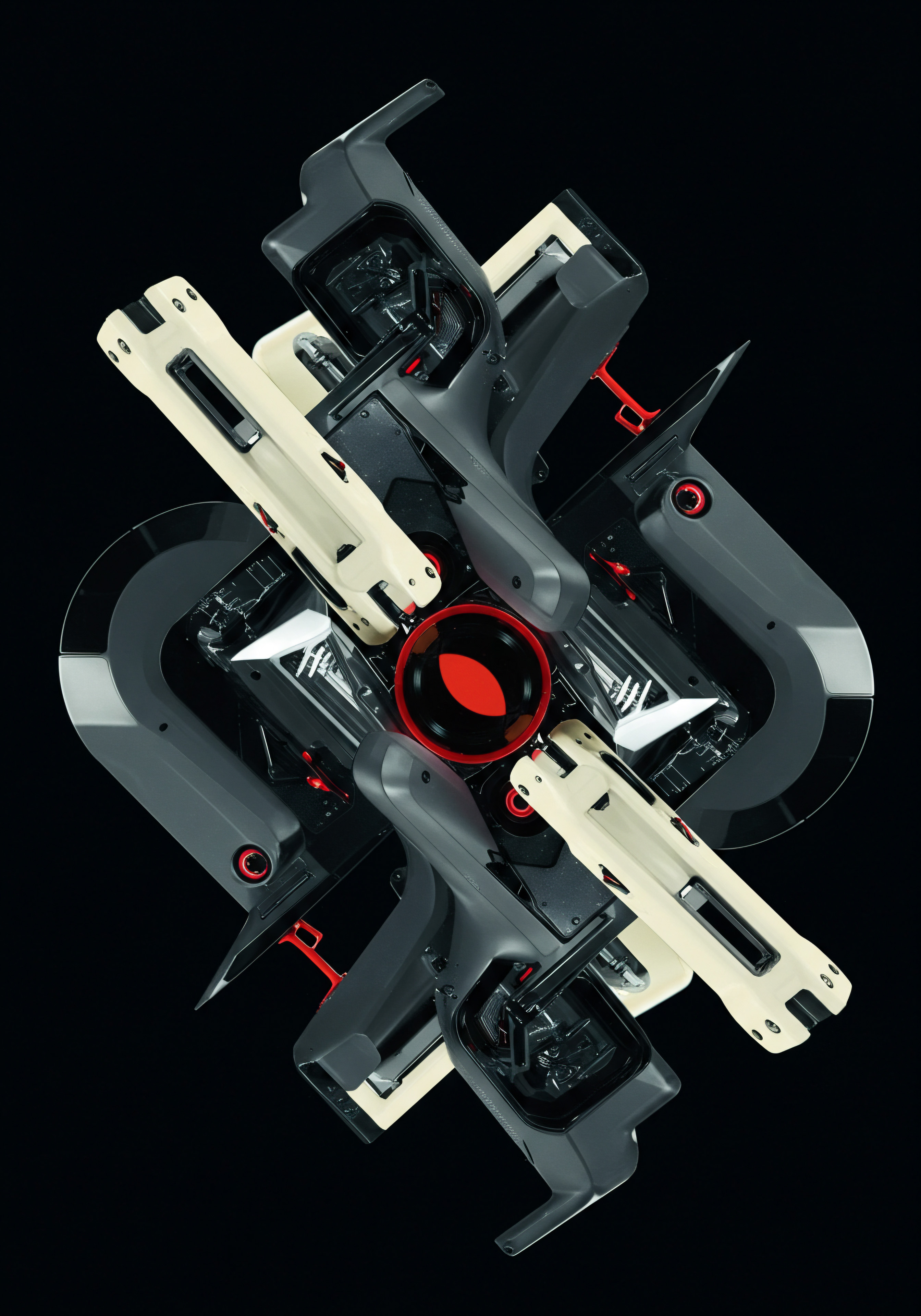

At the advanced level, Predictive Supply Chain Resilience transcends mere risk mitigation Meaning ● Within the dynamic landscape of SMB growth, automation, and implementation, Risk Mitigation denotes the proactive business processes designed to identify, assess, and strategically reduce potential threats to organizational goals. and operational adaptation. It evolves into a strategic capability, deeply embedded within the organizational DNA of SMBs, driving innovation, competitive advantage, and long-term sustainable growth. Moving beyond reactive and even proactive measures, advanced resilience becomes about Antifragility ● not just withstanding shocks, but actually becoming stronger from them.

This necessitates a paradigm shift, viewing disruptions not as threats, but as catalysts for learning, adaptation, and ultimately, evolution. For SMBs to achieve this level of resilience, they must embrace cutting-edge technologies, cultivate dynamic capabilities, and foster a culture of continuous learning Meaning ● Continuous Learning, in the context of SMB growth, automation, and implementation, denotes a sustained commitment to skill enhancement and knowledge acquisition at all organizational levels. and adaptation.

Advanced Predictive Supply Chain Resilience for SMBs is about achieving antifragility, transforming disruptions into catalysts for growth through cutting-edge technologies, dynamic capabilities, and a culture of continuous learning.

Redefining Predictive Supply Chain Resilience ● An Expert Perspective

After a comprehensive exploration, we arrive at an advanced definition of Predictive Supply Chain Resilience, tailored for the unique context of SMBs ● Predictive Supply Chain Resilience for SMBs is the dynamic organizational capability to leverage advanced analytics, real-time visibility, and adaptive systems to not only anticipate and mitigate supply chain disruptions, but to also learn and evolve from these events, transforming vulnerabilities into opportunities for innovation, competitive differentiation, and sustainable growth Meaning ● Sustainable SMB growth is balanced expansion, mitigating risks, valuing stakeholders, and leveraging automation for long-term resilience and positive impact. within a complex and uncertain global business environment.

This definition emphasizes several key advanced concepts:

- Dynamic Organizational Capability ● Resilience is not a static state but an evolving capability that must be continuously cultivated and adapted. It’s embedded in organizational processes, culture, and strategic decision-making. Dynamic Capability emphasizes adaptability and evolution.

- Advanced Analytics and Real-Time Visibility ● Moving beyond basic data analysis, advanced resilience leverages sophisticated analytics techniques like machine learning, AI-driven forecasting, and real-time monitoring through IoT and digital twin technologies. Advanced Analytics unlock deeper insights and foresight.

- Adaptive Systems ● Resilient supply chains Meaning ● Dynamic SMB networks adapting to disruptions, ensuring business continuity and growth. are not rigid but adaptive, capable of reconfiguring themselves in response to changing conditions. This involves implementing flexible technologies, agile processes, and decentralized decision-making structures. Adaptive Systems enable agile reconfiguration.

- Learning and Evolution from Disruptions ● Advanced resilience is not just about bouncing back to the previous state, but about learning from disruptions and emerging stronger. This requires robust feedback loops, knowledge management systems, and a culture that embraces experimentation and learning from failures. Disruption-Driven Learning fuels antifragility.

- Transformation of Vulnerabilities into Opportunities ● Antifragile systems thrive on volatility. Advanced resilience seeks to identify vulnerabilities not as weaknesses, but as potential areas for innovation and competitive advantage. Disruptions can reveal inefficiencies, highlight unmet needs, and create opportunities for new products, services, or business models. Vulnerability Transformation unlocks innovation.

- Complex and Uncertain Global Business Environment ● This definition acknowledges the increasingly complex and unpredictable nature of the modern global supply chain, characterized by geopolitical instability, climate change, technological disruptions, and evolving customer expectations. Global Complexity necessitates advanced resilience.

Advanced Technologies and Methodologies for Predictive Resilience

Achieving this advanced level of Predictive Supply Chain Resilience requires SMBs to strategically adopt and integrate cutting-edge technologies and methodologies. While the initial investment might seem daunting, the long-term benefits in terms of enhanced resilience, efficiency, and competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. are substantial.

Artificial Intelligence and Machine Learning (AI/ML)

AI and ML are at the forefront of advanced predictive capabilities, offering SMBs unprecedented tools for forecasting, risk assessment, and automated decision-making:

- Demand Forecasting with AI/ML ● Traditional forecasting methods often struggle with complex, non-linear demand patterns. AI/ML algorithms can analyze vast datasets, including historical sales, external factors (weather, social media trends, economic indicators), and real-time data to generate highly accurate demand forecasts, even for volatile markets. AI-Driven Forecasting enhances accuracy and adaptability.

- Predictive Risk Analytics ● AI/ML can be used to develop sophisticated risk models that identify and assess potential supply chain disruptions. These models can analyze diverse data sources to predict supplier failures, transportation bottlenecks, geopolitical risks, and even cybersecurity threats, providing early warnings and enabling proactive mitigation. AI-Powered Risk Models provide early warnings.

- Automated Anomaly Detection ● ML algorithms can be trained to identify anomalies and deviations from normal patterns in supply chain data, such as unexpected delays, quality issues, or demand fluctuations. Automated anomaly detection systems can trigger alerts and initiate automated responses, minimizing the impact of disruptions. Automated Anomaly Detection enables rapid response.

- AI-Driven Optimization ● AI can be used to optimize complex supply chain decisions in real-time, such as inventory management, routing optimization, and supplier selection. AI-powered optimization algorithms can consider multiple constraints and objectives to find the most efficient and resilient solutions, adapting to changing conditions dynamically. AI-Driven Optimization enhances efficiency and resilience.

Digital Twins and Simulation Modeling

Digital twin technology, coupled with advanced simulation modeling, offers SMBs a powerful tool for understanding, testing, and optimizing their supply chain resilience:

- Digital Twin of the Supply Chain ● A digital twin is a virtual representation of the physical supply chain, mirroring its structure, processes, and data in real-time. This digital replica allows SMBs to visualize their entire supply chain, monitor its performance, and simulate the impact of potential disruptions. Digital Twin provides real-time visibility and simulation.

- Scenario Simulation and Stress Testing ● Using the digital twin, SMBs can conduct sophisticated scenario simulations and stress tests to assess the resilience of their supply chain under various disruption scenarios (e.g., supplier failures, natural disasters, demand shocks). This allows them to identify vulnerabilities, evaluate different mitigation strategies, and optimize their resilience plans. Scenario Simulation stress-tests resilience.

- Predictive Maintenance and Asset Management ● Digital twins can be integrated with IoT sensors and predictive maintenance Meaning ● Predictive Maintenance for SMBs: Proactive asset management using data to foresee failures, optimize operations, and enhance business resilience. algorithms to monitor the health and performance of critical supply chain assets, such as machinery, transportation vehicles, and warehouse equipment. This enables proactive maintenance, reducing downtime and improving operational reliability. Predictive Maintenance enhances operational uptime.

- Dynamic Network Optimization ● Digital twins can be used to dynamically optimize the supply chain network in response to real-time events and predicted disruptions. By simulating different network configurations and routing options, SMBs can identify the most resilient and efficient network design, adapting to changing conditions proactively. Dynamic Network Optimization enables adaptive design.

Blockchain and Distributed Ledger Technology (DLT)

Blockchain and DLT offer transformative potential for enhancing supply chain transparency, security, and resilience, particularly in complex and multi-tiered supply networks:

- Enhanced Supply Chain Transparency ● Blockchain provides an immutable and transparent record of transactions and events across the supply chain. This enhances visibility into product provenance, material origins, and ownership history, reducing risks related to counterfeiting, ethical sourcing, and regulatory compliance. Blockchain Transparency builds trust and accountability.

- Improved Traceability and Trackability ● Blockchain enables end-to-end traceability and trackability of goods throughout the supply chain. This is crucial for quickly identifying and isolating affected products in case of quality issues, recalls, or disruptions, minimizing the impact on customers and brand reputation. Blockchain Traceability accelerates incident response.

- Secure Data Sharing and Collaboration ● Blockchain facilitates secure and permissioned data sharing among supply chain partners, fostering collaboration and information exchange without compromising data privacy or security. This enables more efficient coordination, faster response to disruptions, and improved overall supply chain resilience. Secure Data Sharing fosters collaboration.

- Smart Contracts for Automated Processes ● Smart contracts, self-executing contracts coded on the blockchain, can automate various supply chain processes, such as payments, order fulfillment, and quality certifications. This reduces manual errors, speeds up transactions, and enhances efficiency and resilience. Smart Contracts automate processes and improve efficiency.

Cultivating Dynamic Capabilities for Antifragile Resilience

Technology alone is not sufficient to achieve advanced Predictive Supply Chain Resilience. SMBs must also cultivate dynamic capabilities Meaning ● Organizational agility for SMBs to thrive in changing markets by sensing, seizing, and transforming effectively. ● organizational processes and routines that enable them to sense, seize, and reconfigure resources to adapt to rapidly changing environments. These capabilities are crucial for transforming disruptions into opportunities and building antifragility.

Sensing Capabilities ● Enhanced Risk Awareness and Early Warning

Advanced sensing capabilities go beyond basic risk assessments and involve developing sophisticated systems for monitoring the external environment and detecting early warning signals of potential disruptions:

- Real-Time Risk Monitoring Dashboards ● Implement real-time risk monitoring dashboards that aggregate data from diverse sources (internal systems, external data feeds, social media) to provide a holistic and up-to-date view of potential supply chain risks. These dashboards should visualize key risk indicators, trigger alerts for anomalies, and facilitate rapid risk assessment. Real-Time Risk Dashboards provide holistic awareness.

- Advanced Early Warning Systems ● Develop advanced early warning systems that leverage AI/ML algorithms to analyze data patterns and predict potential disruptions before they fully materialize. These systems should identify subtle signals and weak signals that might be missed by traditional monitoring methods, providing valuable lead time for proactive mitigation. Advanced Early Warning Systems predict disruptions proactively.

- Scenario Planning and Futures Thinking ● Go beyond reactive scenario planning to proactive futures thinking. Regularly conduct workshops and exercises to explore potential future scenarios, including disruptive technologies, geopolitical shifts, and climate change impacts. This helps SMBs anticipate future challenges and develop long-term resilience strategies. Futures Thinking anticipates long-term challenges.

- Continuous Environmental Scanning ● Establish a continuous environmental scanning process to actively monitor the external environment for emerging trends, potential threats, and opportunities. This involves systematically collecting and analyzing information from diverse sources, including industry reports, academic research, news media, and social media, to stay ahead of the curve. Continuous Scanning maintains external awareness.

Seizing Capabilities ● Agile Response and Adaptive Execution

Seizing capabilities are about translating risk awareness into agile responses and adaptive execution. This involves developing organizational agility, flexible processes, and decentralized decision-making:

- Agile Supply Chain Processes ● Implement agile methodologies in supply chain operations, such as iterative planning, rapid prototyping, and flexible execution. Agile processes enable SMBs to quickly adapt to changing demands, unexpected disruptions, and new opportunities. Agile Processes enable rapid adaptation.

- Modular and Reconfigurable Operations ● Design modular and reconfigurable operational systems that can be quickly adapted or reconfigured in response to disruptions. This could involve modular production lines, flexible warehousing solutions, and adaptable transportation networks. Modular Operations enhance reconfigurability.

- Decentralized Decision-Making ● Empower frontline employees and local teams to make decisions quickly and autonomously in response to local disruptions. Decentralized decision-making reduces bottlenecks, accelerates response times, and fosters a culture of ownership and accountability. Decentralized Decisions accelerate response.

- Dynamic Resource Allocation ● Develop systems for dynamically reallocating resources (inventory, personnel, equipment) across the supply chain in response to disruptions or changing demands. This ensures that resources are deployed where they are most needed, maximizing efficiency and resilience. Dynamic Resource Allocation optimizes resource utilization.

Reconfiguring Capabilities ● Learning, Innovation, and Transformation

Reconfiguring capabilities are about learning from disruptions, driving innovation, and transforming the organization to emerge stronger and more resilient. This involves fostering a culture of learning, embracing experimentation, and driving continuous improvement:

- Robust Feedback Loops Meaning ● Feedback loops are cyclical processes where business outputs become inputs, shaping future actions for SMB growth and adaptation. and Learning Systems ● Establish robust feedback loops to capture lessons learned from disruptions and integrate them into organizational processes and strategies. Implement knowledge management systems Meaning ● Strategic organization of internal expertise for SMB efficiency and growth. to codify and share best practices and lessons learned across the organization. Feedback Loops drive continuous learning.

- Culture of Experimentation and Innovation ● Foster a culture of experimentation Meaning ● Within the context of SMB growth, automation, and implementation, a Culture of Experimentation signifies an organizational environment where testing new ideas and approaches is actively encouraged and systematically pursued. and innovation that encourages employees to try new approaches, test new technologies, and learn from failures. This culture of continuous improvement is essential for driving innovation and building antifragility. Experimentation Culture fosters innovation.

- Disruption-Driven Innovation ● View disruptions not just as problems to be solved, but as opportunities for innovation. Analyze disruptions to identify unmet needs, inefficiencies, and new market opportunities. Use these insights to drive product innovation, process improvements, and business model transformations. Disruption-Driven Innovation unlocks new opportunities.

- Adaptive Organizational Structure ● Design an adaptive organizational structure that is flexible, decentralized, and responsive to change. This could involve flatter hierarchies, cross-functional teams, and network-based organizational models. Adaptive structures facilitate agility and resilience. Adaptive Structures enable organizational agility.

The SMB Advantage ● Agility and Adaptability as Resilience Drivers

While large corporations often struggle with bureaucratic inertia and complex legacy systems, SMBs possess inherent advantages in building advanced Predictive Supply Chain Resilience. Their agility, adaptability, and entrepreneurial spirit are powerful assets that can be leveraged to outpace larger competitors in building resilient and antifragile supply chains.

Here’s how SMBs can leverage their inherent advantages:

- Faster Decision-Making ● SMBs typically have flatter organizational structures and faster decision-making processes compared to large corporations. This allows them to respond more quickly to disruptions, adapt to changing conditions, and implement innovative solutions rapidly. Fast Decision-Making is a key SMB advantage.

- Greater Flexibility and Adaptability ● SMBs are generally more flexible and adaptable in their operations and processes. They can pivot quickly, adjust production lines, and reconfigure their supply chains more easily than larger, more rigid organizations. Operational Flexibility enhances SMB agility.

- Stronger Customer Relationships ● SMBs often have closer relationships with their customers and suppliers, fostering trust, collaboration, and open communication. These strong relationships are invaluable in building resilient supply chains, enabling faster information sharing and coordinated responses to disruptions. Strong Relationships build trust and collaboration.

- Innovation and Entrepreneurial Spirit ● SMBs are often driven by innovation and an entrepreneurial spirit. They are more willing to experiment with new technologies, adopt innovative solutions, and challenge conventional approaches to supply chain management. This innovative mindset is crucial for building advanced resilience. Entrepreneurial Spirit drives innovation and resilience.

By embracing these inherent advantages and strategically implementing advanced technologies and dynamic capabilities, SMBs can not only build highly resilient supply chains but also transform disruptions into catalysts for growth, innovation, and sustainable competitive advantage Meaning ● SMB SCA: Adaptability through continuous innovation and agile operations for sustained market relevance. in the increasingly complex and unpredictable global marketplace.

Advanced resilience for SMBs leverages their inherent agility and adaptability, transforming disruptions into opportunities for innovation and sustainable competitive advantage through strategic technology adoption and dynamic capabilities.