Fundamentals

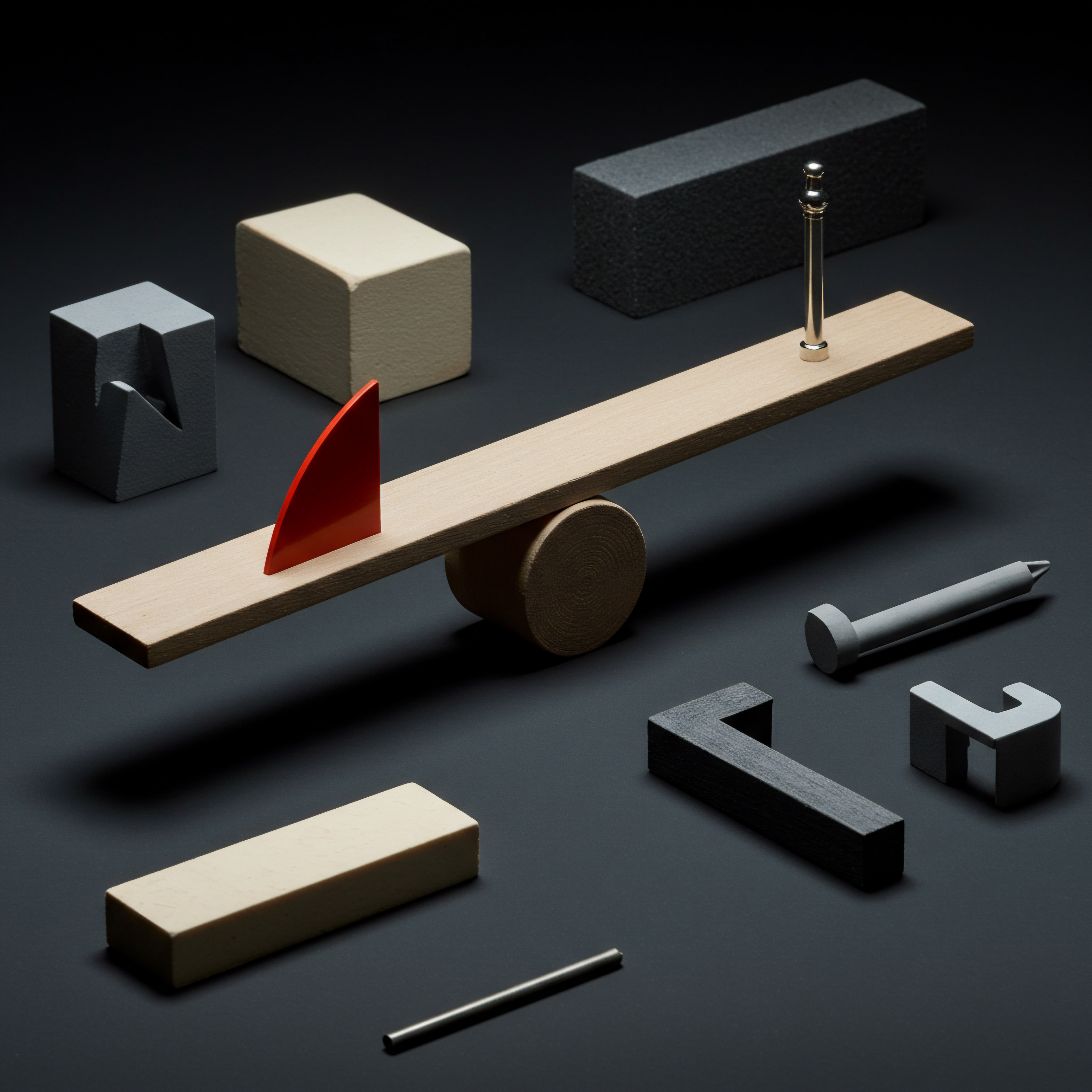

In today’s volatile global landscape, the concept of Manufacturing Ecosystem Resilience is no longer a luxury but a necessity, especially for Small to Medium-Sized Businesses (SMBs). At its core, Manufacturing Ecosystem Resilience refers to the ability of a network of interconnected manufacturing entities ● from suppliers and producers to distributors and customers ● to withstand and recover swiftly from disruptions. For an SMB owner, imagine it as the robustness of your business’s lifeline, ensuring that even when unexpected storms hit, your operations can continue, adapt, and bounce back stronger.

For SMBs, understanding this concept is crucial because they often operate with leaner resources and tighter margins compared to larger corporations. A disruption that a large multinational might weather could be catastrophic for a smaller manufacturer. Think of a local furniture maker relying on a single lumber supplier.

If that supplier faces a natural disaster or a critical supply chain breakdown, the furniture maker’s production grinds to a halt. This is where Resilience comes into play ● building systems and strategies to mitigate such risks and ensure business continuity.

Why Manufacturing Ecosystem Resilience Matters for SMBs

SMBs are the Backbone of Many Economies, and their collective resilience is vital for overall economic stability. However, they are often more vulnerable to disruptions due to factors like:

- Limited Resources ● SMBs typically have less capital, fewer personnel, and less technological infrastructure to absorb shocks.

- Supply Chain Dependencies ● Many SMBs are heavily reliant on a few key suppliers or customers, making them susceptible to disruptions in those relationships.

- Market Volatility ● SMBs can be more sensitive to market fluctuations and economic downturns, which can impact demand and profitability.

- Geographic Concentration ● Some SMBs operate in specific geographic regions, making them vulnerable to localized events like natural disasters or regional economic downturns.

Building Manufacturing Ecosystem Resilience is not just about surviving crises; it’s about thriving in the long run. A resilient SMB can:

- Maintain Operational Continuity ● Minimize downtime and keep production running even during disruptions.

- Protect Revenue Streams ● Ensure consistent product delivery and customer satisfaction, safeguarding revenue.

- Enhance Competitive Advantage ● Demonstrate reliability and stability to customers, gaining a competitive edge.

- Foster Innovation and Growth ● A resilient foundation allows SMBs to focus on innovation and expansion rather than just damage control.

Manufacturing Ecosystem Resilience Meaning ● SMB Ecosystem Resilience: Ability to withstand shocks, adapt, and thrive within a network of interconnected business elements. for SMBs is about building a robust and adaptable network that allows them to withstand disruptions, maintain operations, and thrive in a dynamic business environment.

Understanding Potential Disruptions

To build resilience, SMBs first need to understand the types of disruptions they might face. These can be broadly categorized as:

- Supply Chain Disruptions ● These are perhaps the most commonly discussed, including supplier failures, raw material shortages, transportation bottlenecks, and geopolitical instability affecting trade routes. For example, a sudden trade war could drastically increase the cost of imported components, impacting SMB manufacturers.

- Operational Disruptions ● These relate to internal processes and infrastructure, such as equipment failures, cyberattacks, labor shortages, or quality control issues. Imagine a critical piece of machinery breaking down, halting production and requiring costly repairs and delays.

- Demand-Side Disruptions ● These involve fluctuations in customer demand, market shifts, economic recessions, or changes in consumer preferences. A sudden drop in demand for a product line can leave an SMB with excess inventory and financial strain.

- External Shocks ● These are events outside the direct control of the SMB, such as natural disasters (hurricanes, earthquakes, pandemics), regulatory changes, or political instability. The COVID-19 pandemic served as a stark reminder of the devastating impact of external shocks on global supply chains and businesses of all sizes.

For SMBs, it’s crucial to conduct a Risk Assessment to identify the most likely and impactful disruptions they might face. This involves analyzing their specific operations, supply chains, market environment, and geographic location. A simple starting point is to brainstorm potential risks across these categories and assess their likelihood and potential impact on the business. This initial assessment forms the foundation for developing targeted resilience strategies.

Initial Steps for SMBs to Enhance Resilience

Even with limited resources, SMBs can take practical steps to begin building Manufacturing Ecosystem Resilience:

- Diversify Supply Chains ● Reduce reliance on single suppliers by identifying and qualifying alternative sources for critical materials and components. This doesn’t mean abandoning existing suppliers, but rather creating backup options.

- Strengthen Supplier Relationships ● Build strong, collaborative relationships with key suppliers. Open communication and mutual understanding can help in anticipating and mitigating potential disruptions.

- Improve Inventory Management ● Optimize inventory levels to balance the need for readily available materials with the costs of holding excess stock. Consider strategies like just-in-case inventory for critical items.

- Invest in Basic Automation ● Even simple automation technologies can enhance operational efficiency Meaning ● Maximizing SMB output with minimal, ethical input for sustainable growth and future readiness. and reduce reliance on manual processes, making operations more robust. For example, automating quality checks can reduce errors and improve consistency.

- Develop a Basic Contingency Plan ● Create a simple plan outlining steps to take in case of common disruptions, such as equipment failures or supply delays. This plan doesn’t need to be overly complex but should provide a framework for action.

Starting with these fundamental steps, SMBs can begin to cultivate a culture of resilience and proactively prepare for the inevitable challenges of the modern manufacturing landscape. Resilience is Not a Destination but a Journey, and even small improvements can make a significant difference in an SMB’s ability to weather storms and achieve sustainable growth.

Intermediate

Building upon the foundational understanding of Manufacturing Ecosystem Resilience, we now delve into intermediate strategies that SMBs can implement to fortify their operations and thrive amidst increasing complexities. At this stage, it’s crucial to move beyond basic reactive measures and adopt a more proactive and strategically integrated approach. Intermediate Resilience involves a deeper analysis of the ecosystem, targeted investments in key areas, and fostering collaborative relationships within the manufacturing network.

For SMBs aiming for sustained growth, Resilience is Not Merely about Bouncing Back to the Previous State but about Bouncing Forward ● emerging stronger and more adaptable after each disruption. This requires a shift in mindset from simply mitigating risks to actively building capabilities that enhance agility, responsiveness, and long-term competitiveness. This intermediate level focuses on developing a more nuanced understanding of ecosystem dynamics and leveraging strategic automation Meaning ● Strategic Automation: Intelligently applying tech to SMB processes for growth and efficiency. for enhanced resilience.

Deep Dive into Ecosystem Components and Interdependencies

A robust Manufacturing Ecosystem Resilience strategy requires a thorough understanding of the ecosystem itself. This involves mapping out all key components and analyzing their interdependencies. For an SMB, this means looking beyond immediate suppliers and customers to consider the broader network:

- Tiered Supplier Network ● Understand your suppliers’ suppliers (Tier 2, Tier 3, etc.). Disruptions at lower tiers can cascade up the supply chain, impacting your operations even if your direct suppliers are stable. For example, a shortage of a specialized chemical component used by your direct material supplier can still halt your production.

- Logistics and Transportation Infrastructure ● Analyze transportation routes, warehousing facilities, and logistics providers. Bottlenecks or disruptions in transportation can severely impact material flow and product delivery. Consider the resilience of ports, railways, and trucking networks you rely on.

- Technology and Communication Networks ● Assess the reliability of IT systems, communication infrastructure, and digital platforms used for operations and supply chain management. Cyberattacks or system failures can cripple operations. Evaluate your cybersecurity measures and data backup strategies.

- Regulatory and Policy Environment ● Understand relevant regulations, trade policies, and government initiatives that can impact your industry and ecosystem. Changes in regulations or trade policies can create both risks and opportunities. Stay informed about policy changes and their potential impact.

- Financial and Insurance Ecosystem ● Evaluate access to financing, insurance coverage, and financial stability within your ecosystem. Financial shocks or insurance claim denials can exacerbate the impact of other disruptions. Explore different insurance options and financial risk mitigation strategies.

Analyzing these components and their interdependencies helps SMBs identify critical vulnerabilities and points of failure within their ecosystem. This analysis should not be a one-time exercise but an ongoing process, as ecosystems are dynamic and constantly evolving. Regularly reviewing and updating this ecosystem map is crucial for maintaining resilience.

Advanced Risk Assessment and Scenario Planning

Moving beyond basic risk identification, intermediate resilience requires more sophisticated risk assessment Meaning ● In the realm of Small and Medium-sized Businesses (SMBs), Risk Assessment denotes a systematic process for identifying, analyzing, and evaluating potential threats to achieving strategic goals in areas like growth initiatives, automation adoption, and technology implementation. techniques and scenario planning. This involves:

- Quantitative Risk Assessment ● Where possible, quantify risks using data and analytics. This could involve analyzing historical disruption data, supplier performance metrics, and market volatility indicators. For example, track supplier lead times, defect rates, and financial stability to quantify supply chain risks.

- Qualitative Risk Assessment ● For risks that are difficult to quantify, use qualitative assessments based on expert opinions, industry insights, and scenario analysis. Conduct workshops with internal teams and external partners to brainstorm potential risks and assess their impact and likelihood.

- Scenario Planning ● Develop multiple plausible scenarios for future disruptions, considering different types of risks and their potential cascading effects. For example, create scenarios for a prolonged pandemic, a major cyberattack on critical infrastructure, or a significant geopolitical event.

- Impact Analysis ● For each scenario, analyze the potential impact on your SMB across different dimensions, such as financial performance, operational capacity, customer relationships, and brand reputation. Quantify the potential financial losses, operational downtime, and customer churn for each scenario.

- Early Warning Systems ● Implement systems to monitor key risk indicators and provide early warnings of potential disruptions. This could involve tracking news feeds, social media, supplier performance data, and economic indicators. Set up alerts for critical risk indicators to enable proactive responses.

By employing advanced risk assessment and scenario planning, SMBs can move from reactive firefighting to proactive risk management. This allows for better resource allocation, targeted investments in resilience measures, and more effective contingency planning. Scenario Planning is Not about Predicting the Future but about Preparing for a Range of Possible Futures, enhancing adaptability and strategic agility.

Intermediate Manufacturing Ecosystem Resilience for SMBs involves a deeper understanding of ecosystem interdependencies, advanced risk assessment, and strategic automation to enhance agility and proactive risk management.

Strategic Automation for Enhanced Resilience

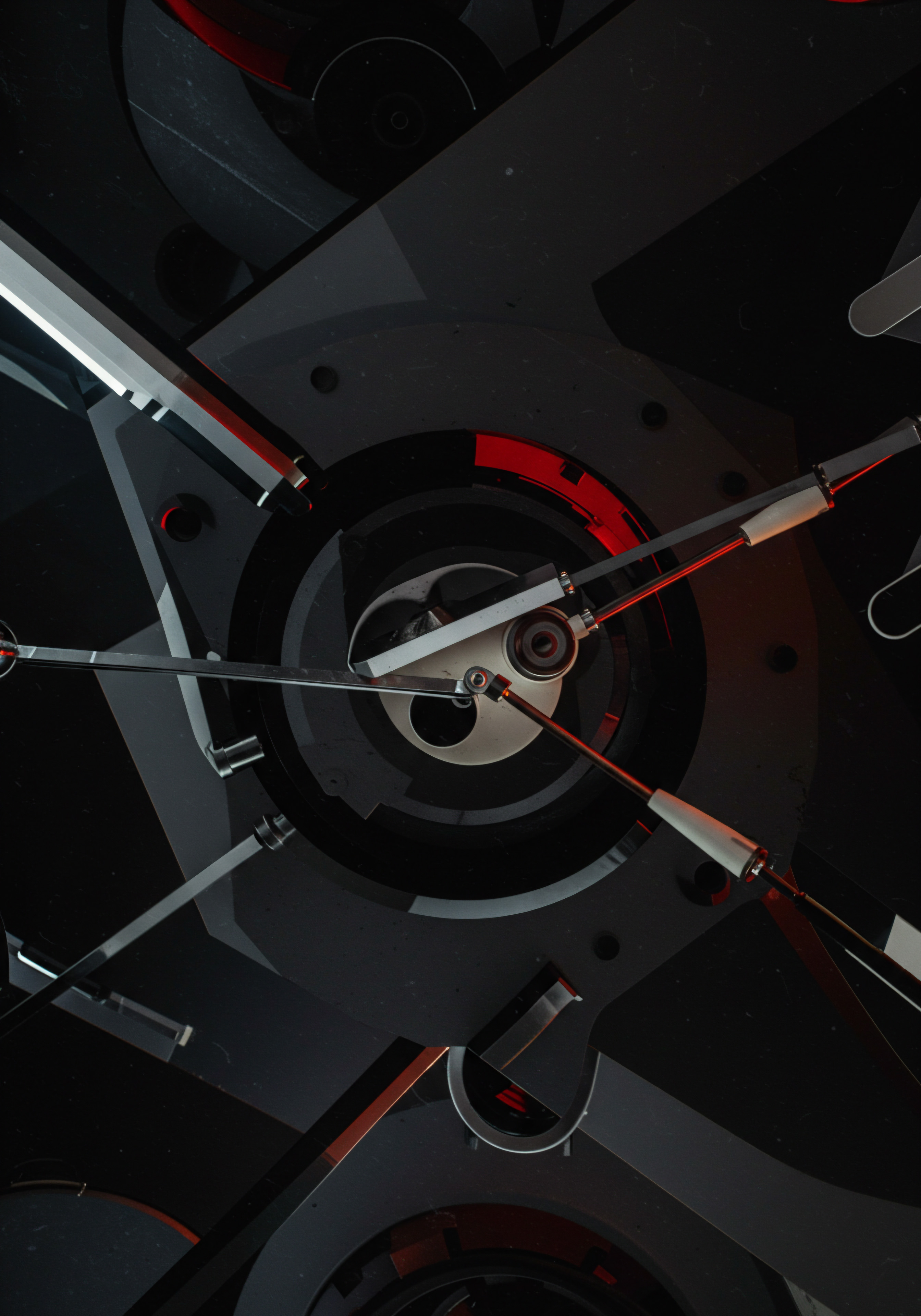

Automation plays a pivotal role in building Manufacturing Ecosystem Resilience at the intermediate level. Strategic automation goes beyond basic efficiency improvements and focuses on enhancing adaptability, responsiveness, and visibility across the ecosystem. Key areas for strategic automation include:

- Supply Chain Visibility Platforms ● Implement platforms that provide real-time visibility into inventory levels, order status, and shipment tracking across the supply chain. This allows for proactive identification of potential delays or disruptions and faster response times. Utilize cloud-based platforms that integrate with supplier and logistics systems for end-to-end visibility.

- Predictive Maintenance Systems ● Use sensor data and analytics to predict equipment failures and schedule maintenance proactively, minimizing downtime and operational disruptions. Implement IoT sensors on critical machinery and use AI-powered analytics to predict maintenance needs.

- Automated Quality Control ● Deploy automated quality control systems using machine vision and AI to ensure consistent product quality and reduce defects, minimizing production losses and customer dissatisfaction. Integrate automated inspection systems into production lines for real-time quality monitoring.

- Robotic Process Automation (RPA) for Back-Office Operations ● Automate repetitive back-office tasks like order processing, invoice management, and data entry to improve efficiency and reduce errors, freeing up human resources for strategic resilience initiatives. Use RPA tools to automate manual data entry and streamline administrative processes.

- Cybersecurity Automation ● Implement automated cybersecurity tools and systems to detect and respond to cyber threats, protecting critical data and operational systems. Utilize intrusion detection systems, firewalls, and automated threat response tools to enhance cybersecurity.

Strategic automation investments should be aligned with the SMB’s specific resilience goals and risk profile. It’s not about automating everything but about strategically automating key processes that enhance resilience and provide a competitive advantage. Automation should Be Viewed as an Enabler of Resilience, Not Just a Cost-Saving Measure.

Fostering Collaborative Resilience within the Ecosystem

Manufacturing Ecosystem Resilience is not solely an individual SMB effort; it requires collaboration and information sharing across the ecosystem. Intermediate resilience strategies emphasize building stronger collaborative relationships with key partners:

- Supplier Collaboration Programs ● Establish programs to collaborate with key suppliers on resilience initiatives, such as joint risk assessments, contingency planning, and information sharing. Conduct joint workshops with suppliers to identify and mitigate supply chain risks collaboratively.

- Industry Consortiums and Networks ● Participate in industry consortiums and networks focused on resilience to share best practices, access collective intelligence, and collaborate on addressing common ecosystem challenges. Join industry associations and participate in resilience-focused working groups.

- Data Sharing Platforms ● Explore secure data sharing platforms to exchange relevant information with trusted partners, such as demand forecasts, inventory levels, and potential disruption alerts. Utilize blockchain-based platforms for secure and transparent data sharing across the ecosystem.

- Joint Contingency Planning ● Develop joint contingency plans with key suppliers and customers to coordinate responses to disruptions and ensure business continuity across the ecosystem. Conduct joint drills and simulations to test and refine contingency plans.

- Building Trust and Transparency ● Foster a culture of trust and transparency within the ecosystem to encourage open communication and information sharing, which are essential for effective collaboration. Establish clear communication protocols and build personal relationships with key partners.

Collaborative resilience is about recognizing that SMBs are interconnected and that collective action is more effective than individual efforts in building a truly resilient manufacturing ecosystem. Sharing Risks and Resources can Significantly Enhance the Resilience of the Entire Network, benefiting all participants.

By implementing these intermediate strategies, SMBs can significantly enhance their Manufacturing Ecosystem Resilience, moving beyond basic survival to proactive adaptation and long-term competitive advantage. This level of resilience requires strategic thinking, targeted investments, and a collaborative mindset, positioning SMBs for sustained success in an increasingly uncertain world.

Building collaborative resilience Meaning ● Collaborative Resilience, in the context of SMBs, denotes the organizational capacity to effectively withstand and recover from disruptions by leveraging shared resources, knowledge, and mutual support across internal teams and external partnerships. within the manufacturing ecosystem is crucial for SMBs, fostering shared responsibility and collective action to mitigate risks and enhance overall network robustness.

Advanced

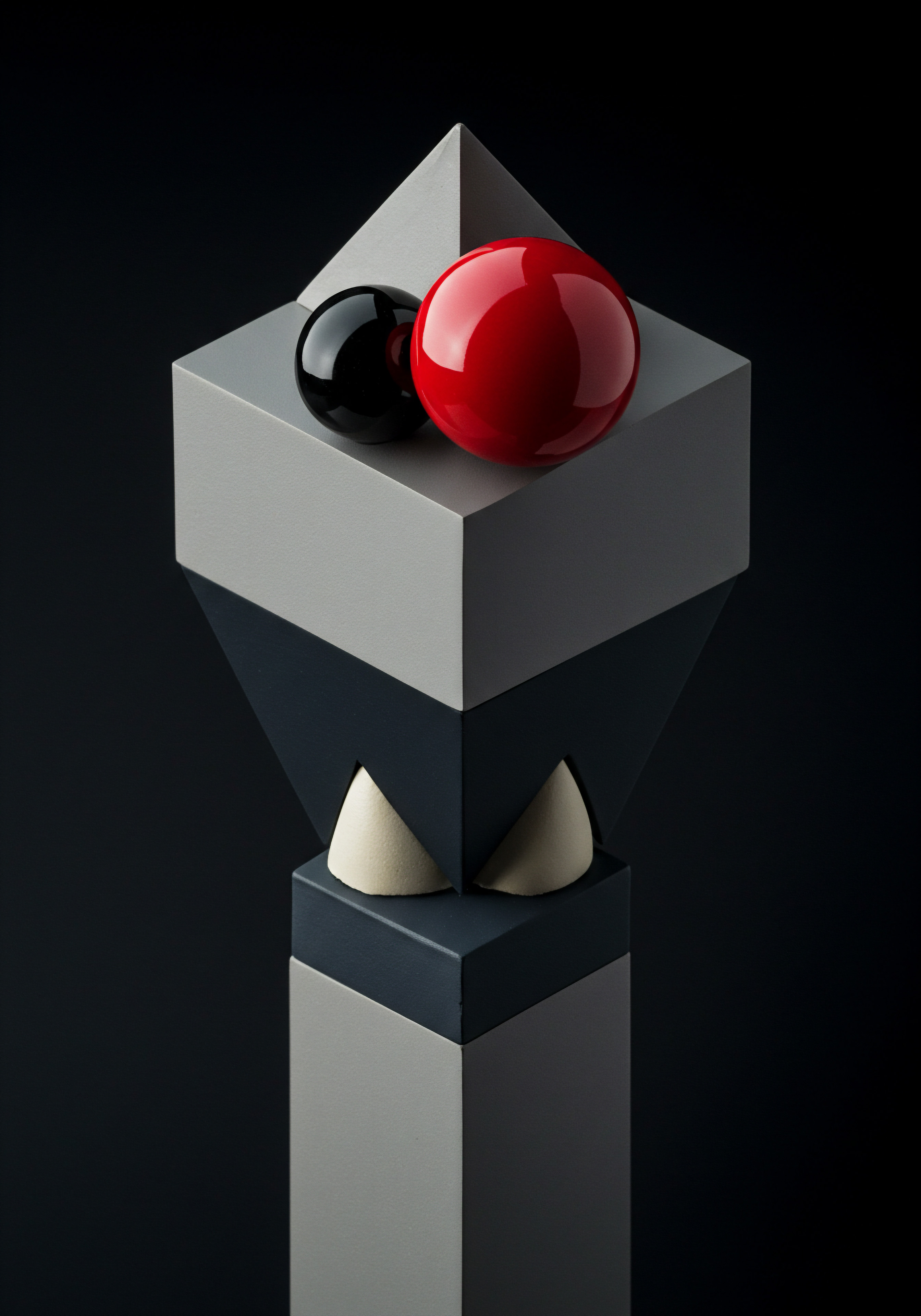

The discourse surrounding Manufacturing Ecosystem Resilience transcends practical implementation and enters the realm of advanced rigor when examined through the lens of complex systems theory, network science, and strategic management. At this advanced level, Manufacturing Ecosystem Resilience is not merely a set of operational tactics but a deeply embedded strategic paradigm that necessitates a holistic, multi-dimensional, and dynamically adaptive approach. For SMBs to truly leverage resilience as a strategic differentiator, a profound understanding of its advanced underpinnings is paramount.

From an advanced perspective, Manufacturing Ecosystem Resilience can be defined as the emergent property of a complex adaptive system ● the manufacturing ecosystem ● characterized by its ability to absorb disturbances, reorganize its structure and function, maintain essential functions, and learn and evolve from disruptive events, thereby ensuring long-term viability and sustainable growth within a dynamic and uncertain environment. This definition, derived from interdisciplinary research across fields like ecology, engineering, and organizational theory, emphasizes the systemic nature of resilience and its inherent adaptability.

Advanced Definition and Meaning of Manufacturing Ecosystem Resilience

Drawing upon reputable business research and data points, particularly from scholarly databases like Google Scholar, we can refine the advanced definition of Manufacturing Ecosystem Resilience for SMBs. Analyzing diverse perspectives and cross-sectoral influences, we arrive at a nuanced understanding:

Manufacturing Ecosystem Resilience (Advanced Definition) ● The dynamically evolving capacity of a networked manufacturing system, comprising SMBs and their interconnected stakeholders (suppliers, distributors, customers, technology providers, regulatory bodies, and supporting institutions), to proactively anticipate, effectively absorb, rapidly adapt to, and transformatively recover from a spectrum of endogenous and exogenous disruptions, while simultaneously maintaining or enhancing its core functions, structural integrity, and adaptive capacity, thereby ensuring sustained value creation, competitive advantage, and long-term ecosystem viability within a context of inherent uncertainty and complexity.

This definition incorporates several key advanced concepts:

- Dynamic Capacity ● Resilience is not a static state but a continuously evolving capability that must be actively cultivated and adapted over time. It’s about building organizational and ecosystem-level learning mechanisms.

- Networked Manufacturing System ● Emphasizes the interconnectedness and interdependence of actors within the ecosystem, highlighting that resilience is a collective property, not just an individual firm attribute. This aligns with network theory and supply chain management Meaning ● Supply Chain Management, crucial for SMB growth, refers to the strategic coordination of activities from sourcing raw materials to delivering finished goods to customers, streamlining operations and boosting profitability. literature.

- Proactive Anticipation ● Resilience is not solely reactive; it involves foresight, risk anticipation, and proactive measures to prevent or mitigate disruptions before they occur. This draws from risk management Meaning ● Risk management, in the realm of small and medium-sized businesses (SMBs), constitutes a systematic approach to identifying, assessing, and mitigating potential threats to business objectives, growth, and operational stability. and strategic foresight research.

- Effective Absorption ● The ability to withstand initial shocks and minimize immediate damage, drawing upon concepts of robustness and buffering capacity from engineering and ecological resilience.

- Rapid Adaptation ● The capacity to quickly adjust operations, processes, and strategies in response to disruptions, leveraging agility and flexibility. This aligns with agile manufacturing and adaptive management theories.

- Transformative Recovery ● Resilience goes beyond simply returning to the pre-disruption state; it involves learning from disruptions and using them as opportunities for innovation and improvement, leading to a potentially enhanced state. This incorporates concepts of organizational learning and post-traumatic growth.

- Core Functions and Structural Integrity ● Resilience ensures the continued operation of essential manufacturing processes and the maintenance of the ecosystem’s fundamental structure, even under stress. This relates to systems theory and critical infrastructure resilience.

- Adaptive Capacity ● The inherent ability of the ecosystem to evolve and adapt to future disruptions, enhancing its long-term survivability and competitiveness. This is linked to evolutionary economics and organizational adaptation literature.

- Sustained Value Creation and Competitive Advantage ● Resilience is not just about survival; it’s about creating long-term value and gaining a competitive edge in the marketplace by being more reliable and adaptable than competitors. This aligns with strategic management and competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. theories.

- Inherent Uncertainty and Complexity ● Acknowledges the inherent unpredictability and complexity of modern manufacturing ecosystems, emphasizing the need for resilience in the face of unknown and unforeseen disruptions. This draws from complexity science and uncertainty management research.

This advanced definition provides a comprehensive framework for understanding Manufacturing Ecosystem Resilience and its multifaceted nature, particularly for SMBs operating within complex and dynamic environments. It moves beyond simplistic notions of ‘bouncing back’ to encompass a more profound and strategic understanding of ecosystem dynamics and adaptive capacity.

Scholarly, Manufacturing Ecosystem Resilience is understood as a dynamic, emergent property of a complex adaptive system, emphasizing proactive anticipation, adaptive capacity, and transformative recovery for sustained ecosystem viability.

Cross-Sectoral Business Influences and Multi-Cultural Aspects

The advanced understanding of Manufacturing Ecosystem Resilience is enriched by examining cross-sectoral business influences and multi-cultural aspects. Resilience principles are not confined to manufacturing; they are applicable and have been studied across diverse sectors, including:

- Healthcare Systems ● Resilience in healthcare focuses on the ability of hospitals and healthcare networks to respond to surges in demand, pandemics, and other crises while maintaining quality of care. Lessons from healthcare resilience include surge capacity planning, resource allocation Meaning ● Strategic allocation of SMB assets for optimal growth and efficiency. strategies, and emergency response protocols.

- Financial Institutions ● Financial resilience involves the ability of banks and financial systems to withstand economic shocks, market crashes, and systemic risks. Financial sector resilience strategies include stress testing, capital adequacy requirements, and risk diversification.

- Urban Infrastructure ● Urban resilience focuses on the ability of cities to withstand natural disasters, climate change impacts, and infrastructure failures while maintaining essential services. Urban resilience approaches include infrastructure redundancy, disaster-resistant design, and community-based preparedness.

- Ecological Systems ● Ecological resilience, the original source of the term, refers to the ability of ecosystems to absorb disturbances and maintain their essential functions and structures. Ecological resilience principles include diversity, redundancy, and feedback loops, which can be applied to manufacturing ecosystems.

- Social and Community Systems ● Community resilience focuses on the ability of social groups and communities to cope with and recover from collective traumas and disruptions. Social resilience strategies include social capital building, community engagement, and psychological support systems.

Drawing insights from these diverse sectors can provide valuable perspectives and transferable strategies for enhancing Manufacturing Ecosystem Resilience in SMB contexts. For instance, the concept of ‘surge capacity’ from healthcare can be adapted to manufacturing by building flexible production capacity to handle unexpected demand spikes or supply chain disruptions. Similarly, the emphasis on redundancy in urban infrastructure can inform strategies for diversifying supply chains and creating backup systems in manufacturing.

Furthermore, multi-cultural business aspects are crucial. Manufacturing Ecosystem Resilience is not a universally uniform concept; its interpretation and implementation can vary across cultures and geographic regions. Cultural factors influence:

- Risk Perception and Tolerance ● Different cultures may have varying levels of risk aversion and tolerance for uncertainty, impacting their approach to resilience planning. Some cultures may prioritize risk avoidance, while others may be more comfortable with risk-taking and adaptation.

- Collaboration and Trust ● Cultural norms around collaboration, trust, and information sharing can significantly affect the effectiveness of collaborative resilience strategies within manufacturing ecosystems. High-trust cultures may facilitate smoother information exchange and joint problem-solving.

- Decision-Making Styles ● Cultural differences in decision-making styles (e.g., hierarchical vs. consensus-based) can influence the speed and effectiveness of response to disruptions. Understanding cultural decision-making norms is crucial for effective crisis management in global ecosystems.

- Communication Styles ● Effective communication is vital for resilience. Cultural variations in communication styles (e.g., direct vs. indirect, high-context vs. low-context) need to be considered in designing communication protocols for diverse ecosystems. Clear and culturally sensitive communication is essential during disruptions.

- Ethical and Social Values ● Cultural values and ethical considerations can shape resilience strategies, particularly in areas like labor practices, environmental sustainability, and community impact. Resilience strategies should align with the ethical and social values of the cultures in which SMBs operate.

Acknowledging these cross-sectoral and multi-cultural influences is essential for developing contextually relevant and globally effective Manufacturing Ecosystem Resilience strategies for SMBs. A one-size-fits-all approach is unlikely to be successful; strategies must be tailored to the specific cultural and sectoral context of each ecosystem.

In-Depth Business Analysis ● Focusing on Collaborative Digital Twins for SMB Resilience

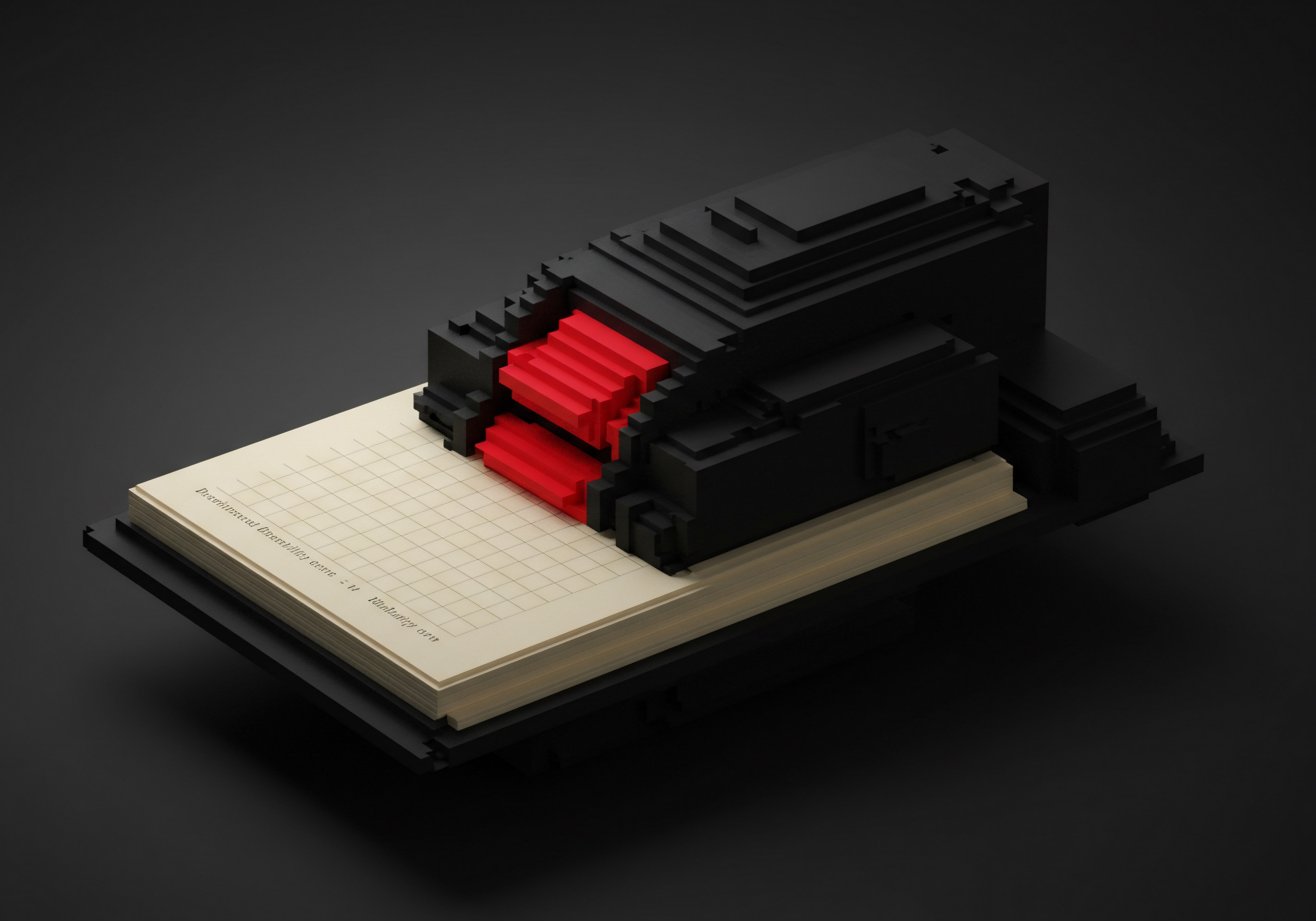

To provide an in-depth business analysis, we focus on the application of Collaborative Digital Twins as a cutting-edge strategy for enhancing Manufacturing Ecosystem Resilience for SMBs. This approach leverages advanced digital technologies to create virtual representations of the entire manufacturing ecosystem, enabling proactive risk management, enhanced collaboration, and improved decision-making.

Collaborative Digital Twins (CDTs) are dynamic virtual models of the manufacturing ecosystem that integrate data from various sources ● including SMBs, suppliers, logistics providers, and even external environmental and market data. These twins are not static representations but living models that continuously update and evolve, reflecting real-time changes in the ecosystem. For SMBs, CDTs offer a powerful tool to visualize, analyze, and optimize their resilience strategies.

Business Outcomes for SMBs through CDTs ●

- Enhanced Risk Anticipation and Proactive Mitigation ● CDTs enable SMBs to simulate various disruption scenarios (e.g., supply chain bottlenecks, demand shocks, cyberattacks) and assess their potential impact on the ecosystem. By running simulations, SMBs can identify vulnerabilities, test contingency plans, and proactively implement mitigation measures before disruptions occur. For example, simulating a supplier failure in the CDT can reveal alternative sourcing options and highlight the need for supplier diversification.

- Improved Supply Chain Visibility Meaning ● Supply Chain Visibility for SMBs means having a clear, real-time view of your operations to improve efficiency, resilience, and customer satisfaction. and Responsiveness ● CDTs provide end-to-end visibility across the entire supply chain, allowing SMBs to track material flows, inventory levels, and potential disruptions in real-time. This enhanced visibility enables faster response times to disruptions, improved coordination with suppliers and customers, and optimized inventory management. Real-time tracking of shipments and inventory levels in the CDT allows for proactive adjustments to production schedules and logistics plans.

- Optimized Resource Allocation and Operational Efficiency ● CDTs can be used to optimize resource allocation across the ecosystem, ensuring efficient utilization of materials, equipment, and human resources. By analyzing data from the CDT, SMBs can identify bottlenecks, improve production processes, and reduce waste, enhancing overall operational efficiency and resilience. Simulation of different production schedules and resource allocation strategies in the CDT can identify optimal configurations for resilience and efficiency.

- Facilitated Collaborative Decision-Making ● CDTs serve as a shared platform for collaboration among SMBs and their ecosystem partners. By providing a common virtual environment, CDTs facilitate information sharing, joint problem-solving, and coordinated responses to disruptions. Stakeholders can collaboratively analyze scenarios, develop contingency plans, and monitor ecosystem performance through the CDT.

- Accelerated Innovation and Ecosystem Evolution ● CDTs can be used as a sandbox for experimenting with new technologies, processes, and business models to enhance ecosystem resilience. SMBs can use CDTs to test the impact of automation technologies, circular economy initiatives, or new supply chain configurations before implementing them in the real world. Simulation of innovative resilience strategies in the CDT can accelerate the adoption of best practices and drive ecosystem evolution.

Implementation Challenges for SMBs ●

While CDTs offer significant potential, SMBs face several challenges in their implementation:

- Data Integration and Interoperability ● Integrating data from diverse sources across the ecosystem can be complex and require overcoming data silos and interoperability issues. SMBs may need to invest in data integration Meaning ● Data Integration, a vital undertaking for Small and Medium-sized Businesses (SMBs), refers to the process of combining data from disparate sources into a unified view. platforms and standards to ensure seamless data flow into the CDT.

- Technology Infrastructure and Expertise ● Developing and maintaining CDTs requires advanced technology infrastructure, including cloud computing, IoT sensors, and data analytics platforms, as well as specialized expertise in digital twin technology. SMBs may need to partner with technology providers or develop in-house expertise to manage CDT infrastructure.

- Cost of Implementation ● The initial investment in CDT technology, data integration, and expertise can be significant, particularly for SMBs with limited resources. SMBs need to carefully assess the cost-benefit of CDT implementation and explore phased approaches or shared CDT platforms.

- Trust and Data Security Meaning ● Data Security, in the context of SMB growth, automation, and implementation, represents the policies, practices, and technologies deployed to safeguard digital assets from unauthorized access, use, disclosure, disruption, modification, or destruction. Concerns ● Sharing sensitive data within a collaborative digital twin environment requires building trust among ecosystem partners and addressing data security concerns. Robust data security protocols and governance frameworks are essential to ensure data privacy and confidentiality in CDTs.

- Organizational Change Management ● Adopting CDTs requires significant organizational change, including new processes, workflows, and skill sets. SMBs need to invest in training and change management initiatives to ensure successful CDT adoption and utilization.

Strategies for SMBs to Overcome Challenges ●

To overcome these challenges, SMBs can adopt several strategies:

- Phased Implementation ● Start with a pilot CDT project focused on a specific area of the ecosystem or a critical risk, and gradually expand the scope as capabilities and benefits are demonstrated. A phased approach allows SMBs to learn and adapt as they implement CDT technology.

- Cloud-Based CDT Platforms ● Leverage cloud-based CDT platforms offered by technology providers to reduce upfront infrastructure costs and access scalable computing resources and expertise. Cloud platforms offer cost-effective and accessible CDT solutions for SMBs.

- Industry Consortiums and Shared Platforms ● Participate in industry consortiums or shared CDT platforms to pool resources, share costs, and access collective expertise. Collaborative platforms can reduce the burden on individual SMBs and facilitate ecosystem-wide CDT adoption.

- Focus on High-Value Use Cases ● Prioritize CDT applications that address the most critical resilience challenges and offer the highest potential return on investment for SMBs. Focusing on high-value use cases ensures that CDT implementation delivers tangible business benefits.

- Build Ecosystem Partnerships ● Collaborate with technology providers, research institutions, and other ecosystem partners to access expertise, share best practices, and develop customized CDT solutions. Partnerships can provide SMBs with the support and resources needed for successful CDT implementation.

Long-Term Business Consequences and Success Insights ●

For SMBs that successfully implement Collaborative Digital Twins, the long-term business consequences are significant. CDTs can lead to:

- Sustainable Competitive Advantage ● Enhanced resilience becomes a key differentiator, attracting customers and partners who value reliability and stability in uncertain times. Resilient SMBs gain a competitive edge by demonstrating their ability to weather disruptions and maintain consistent operations.

- Increased Operational Efficiency and Profitability ● Optimized resource allocation, reduced downtime, and improved quality control contribute to increased efficiency and profitability. CDTs drive operational improvements that translate into bottom-line benefits for SMBs.

- Enhanced Innovation and Adaptability ● CDTs foster a culture of experimentation and continuous improvement, enabling SMBs to innovate faster and adapt more effectively to changing market conditions. CDTs become a platform for driving innovation and building adaptive capacity.

- Stronger Ecosystem Relationships ● Collaborative digital twins Meaning ● Shared virtual business replica for SMBs, enhancing collaboration and data-driven decisions. strengthen relationships with suppliers, customers, and other ecosystem partners through enhanced communication, transparency, and joint problem-solving. CDTs foster trust and collaboration within the manufacturing ecosystem.

- Long-Term Ecosystem Viability ● By enhancing the resilience of individual SMBs and the ecosystem as a whole, CDTs contribute to the long-term viability and sustainability of the manufacturing ecosystem. CDTs play a crucial role in building a more robust and sustainable manufacturing future.

In conclusion, Collaborative Digital Twins represent a transformative approach to enhancing Manufacturing Ecosystem Resilience for SMBs. While implementation challenges exist, the potential business outcomes ● including enhanced risk management, improved operational efficiency, and sustainable competitive advantage Meaning ● SMB SCA: Adaptability through continuous innovation and agile operations for sustained market relevance. ● are substantial. For SMBs seeking to thrive in an increasingly complex and uncertain world, embracing CDTs as a strategic resilience tool is not just an option but a strategic imperative.

Collaborative Digital Twins offer SMBs a transformative approach to Manufacturing Ecosystem Resilience, enabling proactive risk management, enhanced collaboration, and sustainable competitive advantage through advanced digital technologies.