Fundamentals

In the realm of modern business, particularly for Small to Medium-Sized Businesses (SMBs), the concept of Manufacturing Automation Strategy is no longer a futuristic aspiration but a present-day necessity. To understand its fundamental meaning, we must first break down the core components. At its heart, Manufacturing refers to the process of converting raw materials or components into finished goods on a large scale. Automation, in this context, signifies the use of technology ● machinery, control systems, and information technologies ● to reduce the need for human intervention in these manufacturing processes.

Finally, Strategy implies a carefully designed plan of action to achieve a long-term or overall aim. Therefore, in its simplest Definition, a Manufacturing Automation Strategy for an SMB is a planned approach to integrate automated technologies into their manufacturing operations to achieve specific business objectives.

For an SMB just beginning to consider automation, the initial understanding often revolves around replacing manual tasks with machines. This is a valid starting point, but the true Significance of a Manufacturing Automation Strategy extends far beyond mere task replacement. It’s about strategically enhancing efficiency, improving product quality, reducing operational costs, and ultimately, fostering sustainable growth. The Explanation of this strategy for an SMB beginner should emphasize its role as a roadmap.

It’s not about overnight transformation but a phased approach, tailored to the specific needs, resources, and goals of the business. Think of it as a journey, where each step of automation is carefully considered and implemented to build a more robust and competitive manufacturing operation.

The Description of a fundamental Manufacturing Automation Strategy for SMBs often starts with identifying pain points. What are the bottlenecks in the current manufacturing process? Are there issues with consistency in product quality? Are labor costs becoming unsustainable?

These questions help define the areas where automation can provide the most immediate and impactful benefits. For instance, an SMB producing baked goods might identify that the manual packaging process is slow and prone to errors. A fundamental automation strategy Meaning ● Strategic tech integration to boost SMB efficiency and growth. could then focus on implementing automated packaging machinery to address this specific issue. This targeted approach is crucial for SMBs with limited capital and resources.

For SMBs, a fundamental Manufacturing Automation Meaning ● Manufacturing automation for SMBs means strategically using tech to boost efficiency, quality, and competitiveness in their manufacturing processes. Strategy is a phased, targeted approach to integrating technology, starting with addressing key pain points in their manufacturing processes to improve efficiency and quality.

Understanding the Interpretation of automation within an SMB context is also vital. Automation isn’t about eliminating jobs; it’s about evolving them. For SMBs, it often means upskilling the existing workforce to manage and maintain automated systems, rather than mass layoffs. The Clarification here is that automation can create new, higher-skilled roles within the company, leading to a more engaged and productive workforce in the long run.

Consider the example of a small metal fabrication shop. Introducing a CNC (Computer Numerical Control) machine might initially seem like it replaces a manual machinist. However, it also creates the need for CNC programmers and operators, roles that require a different, but equally valuable, skillset.

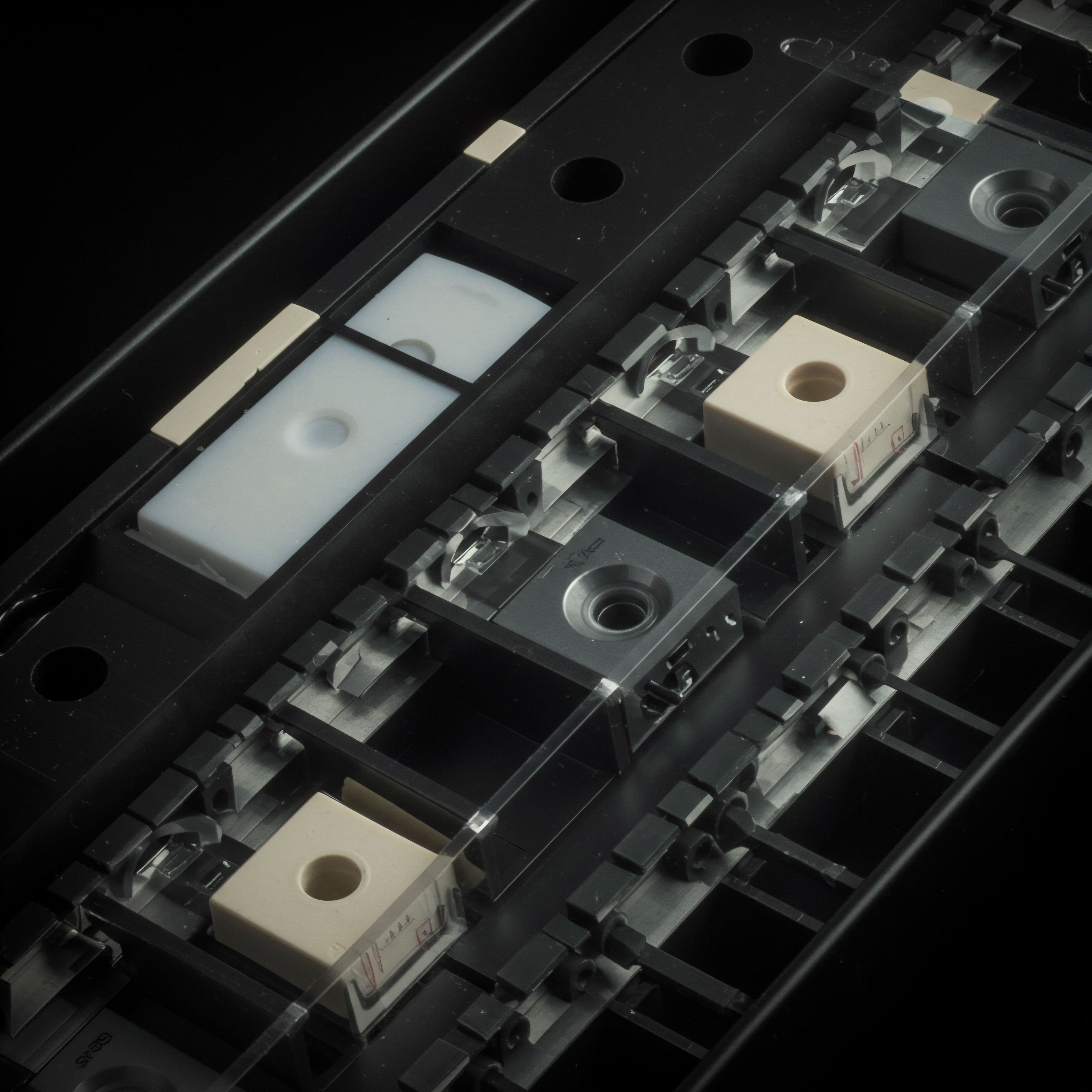

The Elucidation of a fundamental strategy also involves understanding the different types of automation relevant to SMBs. These can range from basic process automation, like automated conveyors and sorting systems, to more advanced technologies like collaborative robots (cobots) that work alongside human workers. The Delineation between these options is crucial for SMBs to make informed decisions.

A small furniture manufacturer, for example, might start with automating material handling using conveyors before considering more complex robotic assembly systems. This phased approach allows for gradual investment and learning.

A clear Specification of the objectives is a cornerstone of any fundamental Manufacturing Automation Strategy. These objectives should be SMART ● Specific, Measurable, Achievable, Relevant, and Time-bound. For an SMB, a specific objective might be to reduce packaging errors by 50% within six months.

This is measurable, achievable with the right automation, relevant to improving product quality and customer satisfaction, and time-bound. The Explication of these objectives ensures that the automation efforts are focused and aligned with the overall business goals.

The Statement of a fundamental strategy should also address the resources required. For SMBs, this is often a critical constraint. The strategy needs to consider not just the initial investment in automation technology but also the ongoing costs of maintenance, training, and potential system upgrades.

A realistic Designation of resources ensures that the automation strategy is financially sustainable for the SMB. This might involve exploring financing options, leasing equipment, or starting with smaller, more manageable automation projects.

The Meaning of success for a fundamental Manufacturing Automation Strategy in an SMB context is multifaceted. It’s not solely about return on investment Meaning ● Return on Investment (ROI) gauges the profitability of an investment, crucial for SMBs evaluating growth initiatives. (ROI), although that is important. It also encompasses improvements in operational efficiency, enhanced product quality, increased employee satisfaction (through reduced repetitive tasks and upskilling opportunities), and a stronger competitive position in the market. The Significance of these broader impacts should not be underestimated, especially for SMBs striving for long-term sustainability Meaning ● Long-Term Sustainability, in the realm of SMB growth, automation, and implementation, signifies the ability of a business to maintain its operations, profitability, and positive impact over an extended period. and growth.

The Sense of urgency for automation in SMBs Meaning ● Automation in SMBs is strategically using tech to streamline tasks, innovate, and grow sustainably, not just for efficiency, but for long-term competitive advantage. is growing. Increased global competition, rising labor costs, and evolving customer expectations are all driving the need for greater efficiency and agility in manufacturing. The Intention behind a fundamental automation strategy is to equip SMBs with the tools and processes to not just survive but thrive in this evolving landscape. It’s about proactively adapting to change and building a more resilient and future-proof business.

The Connotation of automation, particularly in the past, might have been associated with large corporations and massive factories. However, for SMBs, the Implication is different. It’s about democratizing advanced manufacturing technologies, making them accessible and affordable for smaller businesses.

This shift is driven by the increasing availability of cost-effective automation solutions and the growing recognition of the benefits of automation across businesses of all sizes. The Import of this democratization is significant, leveling the playing field and allowing SMBs to compete more effectively with larger enterprises.

The Purport of a well-defined fundamental Manufacturing Automation Strategy is to empower SMBs to take control of their manufacturing processes. It’s about moving from reactive problem-solving to proactive process optimization. The Denotation of this control is increased predictability, reduced variability, and greater responsiveness to market demands. For an SMB, this translates to improved customer satisfaction, stronger brand reputation, and ultimately, increased profitability.

The Substance of a fundamental strategy lies in its practicality and adaptability. It’s not a rigid, one-size-fits-all approach but a flexible framework that can be tailored to the unique circumstances of each SMB. The Essence of this adaptability is crucial for SMBs, which often operate with limited resources and need to be agile in responding to changing market conditions. A successful fundamental strategy is one that evolves with the business, scaling automation efforts as the SMB grows and its needs change.

In summary, for SMBs, a fundamental Manufacturing Automation Strategy is about taking the first, crucial steps towards integrating technology into their operations. It’s about understanding the basic Definition and Meaning of automation, identifying key areas for improvement, setting realistic objectives, and starting with manageable, impactful projects. It’s a journey of continuous improvement, designed to build a more efficient, competitive, and sustainable manufacturing business.

Intermediate

Building upon the foundational understanding of Manufacturing Automation Strategy for SMBs, the intermediate level delves into more nuanced aspects of planning and implementation. At this stage, the Definition of the strategy expands beyond simple task replacement to encompass process optimization Meaning ● Enhancing SMB operations for efficiency and growth through systematic process improvements. and system integration. The Explanation now considers automation not just as individual machines but as interconnected systems working in harmony to achieve broader operational goals. For an SMB at this intermediate level, the focus shifts from addressing immediate pain points to proactively building a more efficient and resilient manufacturing infrastructure.

The Description of an intermediate Manufacturing Automation Strategy involves a more comprehensive analysis of the entire value stream. This includes mapping out all processes from raw material input to finished product output, identifying areas for automation that can yield the greatest overall impact. This holistic approach contrasts with the more targeted approach of the fundamental level.

For example, an SMB producing furniture might have initially automated just the sanding process. At the intermediate level, they would analyze the entire furniture-making process, from lumber cutting to assembly and finishing, to identify further automation opportunities that could streamline the entire production flow.

The Interpretation of automation at this stage becomes more strategic. It’s no longer just about reducing labor costs or increasing throughput in a single process. It’s about leveraging automation to gain a competitive advantage. The Clarification here is that automation can enable SMBs to offer higher quality products, faster lead times, and greater customization options, differentiating them in the market.

Consider an SMB producing custom metal parts. Intermediate-level automation, such as integrated CAD/CAM systems and flexible manufacturing cells, can enable them to efficiently handle smaller batch sizes and complex designs, catering to niche markets and demanding customers.

At the intermediate level, a Manufacturing Automation Strategy for SMBs Meaning ● Strategic use of tech to streamline tasks, boost growth, and gain a competitive edge for SMBs. becomes a holistic, value-stream focused approach, aiming for process optimization and system integration to gain a competitive edge through enhanced quality, speed, and customization.

The Elucidation of an intermediate strategy involves a deeper understanding of different automation technologies and their potential applications. This includes exploring advanced robotics, machine vision systems, industrial IoT (Internet of Things), and data analytics. The Delineation between these technologies and their suitability for different SMB needs becomes crucial. A food processing SMB, for instance, might explore machine vision for quality control and sorting, while a plastics manufacturer might investigate industrial IoT for real-time monitoring of machine performance and predictive maintenance.

The Specification of objectives at the intermediate level becomes more sophisticated. Beyond simple efficiency metrics, objectives now include measures of quality, flexibility, and responsiveness. For example, an SMB might aim to reduce product defects by 75%, decrease lead times by 40%, and increase production flexibility to handle a 30% variation in product demand. The Explication of these multi-faceted objectives reflects the broader strategic goals of the automation initiative.

The Statement of resource requirements at this level also becomes more complex. It’s not just about the capital expenditure for automation equipment but also the investment in IT infrastructure, software integration, cybersecurity, and skilled personnel capable of managing and optimizing these advanced systems. A comprehensive Designation of resources is essential for successful implementation. This might involve developing a detailed budget, securing funding through loans or grants, and investing in employee training and development programs.

The Meaning of success for an intermediate Manufacturing Automation Strategy is measured by its impact on key business performance indicators (KPIs). These KPIs extend beyond operational metrics to include financial performance, customer satisfaction, and market share. The Significance of this broader impact is that automation is now seen as a strategic enabler of overall business success. For example, an SMB might track KPIs such as overall equipment effectiveness (OEE), customer order fulfillment rate, customer retention rate, and revenue growth to assess the effectiveness of their automation strategy.

The Sense of urgency at the intermediate level is driven by the need to maintain and enhance competitiveness in an increasingly dynamic and demanding market. The Intention behind a more advanced automation strategy is to build a sustainable competitive advantage. This involves not just automating existing processes but also innovating and developing new products and services enabled by automation. For instance, an SMB might use automation to offer personalized products or develop new data-driven services for their customers.

The Connotation of automation at this stage shifts from cost reduction Meaning ● Cost Reduction, in the context of Small and Medium-sized Businesses, signifies a proactive and sustained business strategy focused on minimizing expenditures while maintaining or improving operational efficiency and profitability. to value creation. The Implication is that automation is not just about doing things cheaper but also doing things better and creating new value for customers and the business. The Import of this value creation perspective is that automation becomes a driver of innovation and growth, rather than just a cost-saving measure. This might involve using automation to improve product features, enhance customer service, or develop new business models.

The Purport of an intermediate Manufacturing Automation Strategy is to transform the SMB into a more agile, data-driven, and customer-centric organization. The Denotation of this transformation is a shift from reactive, process-oriented operations to proactive, customer-focused, and data-informed decision-making. For an SMB, this translates to greater adaptability to market changes, improved responsiveness to customer needs, and a stronger foundation for future growth.

The Substance of an intermediate strategy lies in its integration and scalability. It’s about building interconnected systems that can seamlessly share data and optimize processes across the entire manufacturing operation. The Essence of this integration is crucial for achieving significant gains in efficiency and responsiveness.

Furthermore, the strategy should be scalable, allowing the SMB to expand its automation efforts as the business grows and its needs evolve. This might involve adopting modular automation solutions, cloud-based platforms, and open architecture systems that can be easily expanded and adapted over time.

In summary, at the intermediate level, a Manufacturing Automation Strategy for SMBs becomes a more strategic and comprehensive undertaking. It’s about moving beyond basic automation to embrace system integration, data-driven decision-making, and value creation. The Definition and Meaning of automation evolve to encompass not just efficiency gains but also competitive advantage, innovation, and long-term business sustainability. This stage requires a deeper understanding of automation technologies, a more holistic approach to process optimization, and a greater commitment to resource investment and organizational change.

Advanced

The advanced exploration of Manufacturing Automation Strategy for SMBs necessitates a rigorous and multifaceted approach, moving beyond practical implementation to examine the theoretical underpinnings, diverse perspectives, and long-term implications of automation within this critical business segment. The Definition, from an advanced standpoint, transcends a mere operational plan; it becomes a strategic paradigm shift, fundamentally altering the nature of SMB manufacturing and its role in the global economy. The Explanation at this level requires a critical analysis of automation’s impact on SMB competitiveness, innovation, workforce dynamics, and societal implications, drawing upon established business theories, empirical research, and cross-disciplinary insights.

The precise Meaning of Manufacturing Automation Strategy, derived from rigorous advanced analysis, is multifaceted and context-dependent. It is not a monolithic concept but rather a spectrum of approaches, each with distinct Significance for SMBs depending on their industry, size, resources, and strategic objectives. After a comprehensive review of scholarly literature and empirical data, we arrive at the following advanced Definition ● Manufacturing Automation Strategy for SMBs is a Dynamic, Knowledge-Driven, and Ethically Informed Organizational Framework That Leverages Advanced Technologies to Enhance Manufacturing Capabilities, Foster Sustainable Competitive Advantage, and Contribute to Societal Value Creation, While Proactively Mitigating Potential Negative Consequences on Workforce and Community. This Definition emphasizes the strategic, knowledge-based, ethical, and societal dimensions of automation, moving beyond a purely technical or operational interpretation.

This Definition is further enriched by considering diverse perspectives. From a technological perspective, Manufacturing Automation Strategy involves the selection, integration, and optimization of various automation technologies, including robotics, AI, IoT, and advanced manufacturing systems. From an economic perspective, it’s about maximizing efficiency, productivity, and profitability, while navigating the complexities of investment, ROI, and market dynamics. From a sociological perspective, it’s about understanding the impact of automation on the workforce, skills development, job displacement, and the changing nature of work in SMB manufacturing.

From an ethical perspective, it necessitates a responsible and human-centered approach to automation, considering fairness, equity, and the well-being of employees and communities. Analyzing these diverse perspectives Meaning ● Diverse Perspectives, in the context of SMB growth, automation, and implementation, signifies the inclusion of varied viewpoints, backgrounds, and experiences within the team to improve problem-solving and innovation. provides a more complete and nuanced understanding of the Meaning of Manufacturing Automation Strategy for SMBs.

Cross-sectorial business influences significantly shape the Meaning and implementation of Manufacturing Automation Strategy in SMBs. For instance, the automotive industry’s push for precision and efficiency drives automation adoption in its SMB suppliers. The consumer electronics sector’s demand for rapid product cycles and customization necessitates flexible automation solutions for SMBs in its supply chain. The pharmaceutical industry’s stringent quality control requirements mandate advanced automation and data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. in SMBs producing medical devices or components.

Analyzing these cross-sectorial influences reveals that the optimal Manufacturing Automation Strategy is not industry-agnostic but must be tailored to the specific demands and dynamics of the SMB’s target market and industry ecosystem. Therefore, focusing on one specific cross-sectorial influence ● the increasing demand for sustainable manufacturing across all sectors ● provides a particularly insightful lens for in-depth business analysis.

From an advanced perspective, Manufacturing Automation Strategy for SMBs is a dynamic, knowledge-driven, and ethically informed framework that leverages technology for competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. and societal value, while mitigating negative workforce impacts.

The rising global imperative for sustainable manufacturing profoundly impacts the Meaning of Manufacturing Automation Strategy for SMBs. Sustainable Manufacturing, in its Definition, encompasses the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. For SMBs, this translates to adopting automation technologies not just for efficiency and profitability, but also for environmental responsibility and social impact. The Explanation of this shift is rooted in growing consumer awareness, stricter environmental regulations, and the increasing business case for sustainability.

Consumers are increasingly demanding eco-friendly products, governments are implementing stricter environmental standards, and investors are prioritizing companies with strong ESG (Environmental, Social, and Governance) performance. For SMBs, integrating sustainability into their Manufacturing Automation Strategy is no longer optional but essential for long-term viability and competitiveness.

The Description of a sustainable Manufacturing Automation Strategy for SMBs involves several key elements. Firstly, it includes adopting energy-efficient automation technologies. This could involve switching to electric-powered machinery, optimizing machine utilization to reduce energy consumption, and implementing smart energy management systems. Secondly, it involves minimizing waste generation through automation.

This could include using precision manufacturing techniques to reduce material waste, implementing automated recycling systems, and adopting closed-loop manufacturing processes. Thirdly, it involves optimizing resource utilization through automation. This could include using automated inventory management systems to reduce material holding costs and waste, implementing water-efficient manufacturing processes, and adopting circular economy Meaning ● A regenerative economic model for SMBs, maximizing resource use and minimizing waste for sustainable growth. principles. Fourthly, it involves enhancing product lifecycle management through automation.

This could include using digital twins to optimize product design for sustainability, implementing automated tracking systems for product end-of-life management, and adopting design for disassembly principles. These elements collectively contribute to a more sustainable and environmentally responsible manufacturing operation.

The Interpretation of sustainability within the context of Manufacturing Automation Strategy for SMBs requires a shift in mindset. It’s not just about complying with regulations or responding to consumer pressure; it’s about recognizing sustainability as a source of competitive advantage and innovation. The Clarification here is that sustainable automation Meaning ● Sustainable Automation: Long-term tech integration for SMB resilience, ethics, and equitable growth. can lead to cost savings through reduced energy consumption and waste, enhanced brand reputation through demonstrated environmental responsibility, and new market opportunities through the development of eco-friendly products and services.

For example, an SMB in the textile industry might adopt automated dyeing and printing technologies that significantly reduce water and chemical usage, leading to both environmental benefits and cost savings. Another SMB in the packaging industry might automate the production of biodegradable packaging materials, tapping into the growing market for sustainable packaging solutions.

The Elucidation of a sustainable automation strategy Meaning ● Sustainable Automation Strategy: Smart tech integration for SMB longevity, balancing growth, ethics, and resilience. also involves considering the social dimension of sustainability. This includes ensuring fair labor practices in automated manufacturing environments, providing opportunities for workforce upskilling and reskilling to adapt to automation, and contributing to community development through sustainable manufacturing initiatives. The Delineation between purely environmental sustainability and broader social sustainability is crucial. A truly sustainable Manufacturing Automation Strategy must address both environmental and social aspects, creating a positive impact on both the planet and people.

For example, an SMB implementing automation should invest in training programs to help employees transition to new roles and skills required in automated environments. They should also consider the impact of automation on local communities and explore opportunities to contribute to community development through job creation or environmental initiatives.

The Specification of objectives for a sustainable Manufacturing Automation Strategy must incorporate both economic and environmental performance metrics. These objectives should be measurable and aligned with recognized sustainability standards and frameworks, such as the UN Sustainable Development Goals (SDGs) or ISO 14001 environmental management standards. For example, an SMB might set objectives to reduce carbon emissions by 30% within five years, decrease waste generation by 50% within three years, and improve energy efficiency by 20% within two years, while simultaneously maintaining or improving profitability and productivity. The Explication of these dual objectives ● economic and environmental ● ensures that the sustainability strategy is both impactful and financially viable.

The Statement of resource requirements for a sustainable automation strategy may initially appear higher due to investments in green technologies and sustainability initiatives. However, a long-term perspective reveals that these investments can lead to significant cost savings and value creation over time. A comprehensive Designation of resources should consider not only the upfront costs but also the long-term benefits, such as reduced energy and material costs, enhanced brand value, and access to green financing options. This might involve conducting a lifecycle cost analysis to assess the total cost of ownership of sustainable automation technologies, exploring government incentives and grants for green investments, and engaging with stakeholders to build support for sustainability initiatives.

The Meaning of success for a sustainable Manufacturing Automation Strategy is measured by its contribution to both business profitability and environmental and social impact. The Significance of this triple bottom line Meaning ● TBL for SMBs: Balancing profit, people, and planet for sustainable business success and positive impact. approach ● people, planet, and profit ● is that it aligns business success with broader societal goals. For SMBs, this means tracking KPIs not only related to financial performance but also to environmental performance (e.g., carbon footprint, waste reduction, energy consumption) and social performance (e.g., employee well-being, community engagement, ethical sourcing). The Sense of purpose for SMBs adopting sustainable automation extends beyond mere profit maximization to encompass a broader mission of creating a positive impact on the world.

The Intention behind a sustainable Manufacturing Automation Strategy is to build a resilient and future-proof business that thrives in a resource-constrained and environmentally conscious world. The Connotation of sustainability is no longer just a niche market trend but a mainstream business imperative. The Implication is that SMBs that proactively embrace sustainable automation will be better positioned to attract customers, investors, and talent, and to navigate the challenges of climate change and resource scarcity. The Import of this proactive approach is that it transforms sustainability from a cost center to a profit center, driving innovation, efficiency, and long-term value creation.

The Purport of a sustainable Manufacturing Automation Strategy is to contribute to a more circular and regenerative economy. The Denotation of this circular economy approach is a shift from a linear “take-make-dispose” model to a closed-loop system where resources are used more efficiently, waste is minimized, and products are designed for durability, reuse, and recycling. For SMBs, this translates to adopting circular economy principles in their manufacturing processes, product design, and business models, leveraging automation to enable circularity.

The Substance of a sustainable strategy lies in its integration of environmental, social, and economic considerations into every aspect of the business. The Essence of this integration is crucial for creating a truly sustainable and responsible manufacturing operation that benefits both the business and society.

In conclusion, the advanced understanding of Manufacturing Automation Strategy for SMBs, particularly through the lens of sustainable manufacturing, reveals a complex and evolving landscape. The Definition and Meaning of automation extend far beyond simple efficiency gains to encompass strategic competitiveness, ethical responsibility, and societal value creation. For SMBs to thrive in the 21st century, their automation strategies must be not only technologically advanced and economically sound but also environmentally sustainable and socially responsible. This requires a holistic, knowledge-driven, and ethically informed approach, integrating diverse perspectives and embracing the transformative potential of automation to build a more sustainable and prosperous future for both SMBs and the world.

To further illustrate the practical application of a sustainable Manufacturing Automation Strategy for SMBs, consider the following examples:

- Energy-Efficient Robotics ● SMBs can invest in robotic systems designed for low energy consumption. These robots often utilize advanced servo motors and intelligent control systems to minimize energy usage during operation and idle periods. This reduces operational costs and lowers the carbon footprint of manufacturing processes.

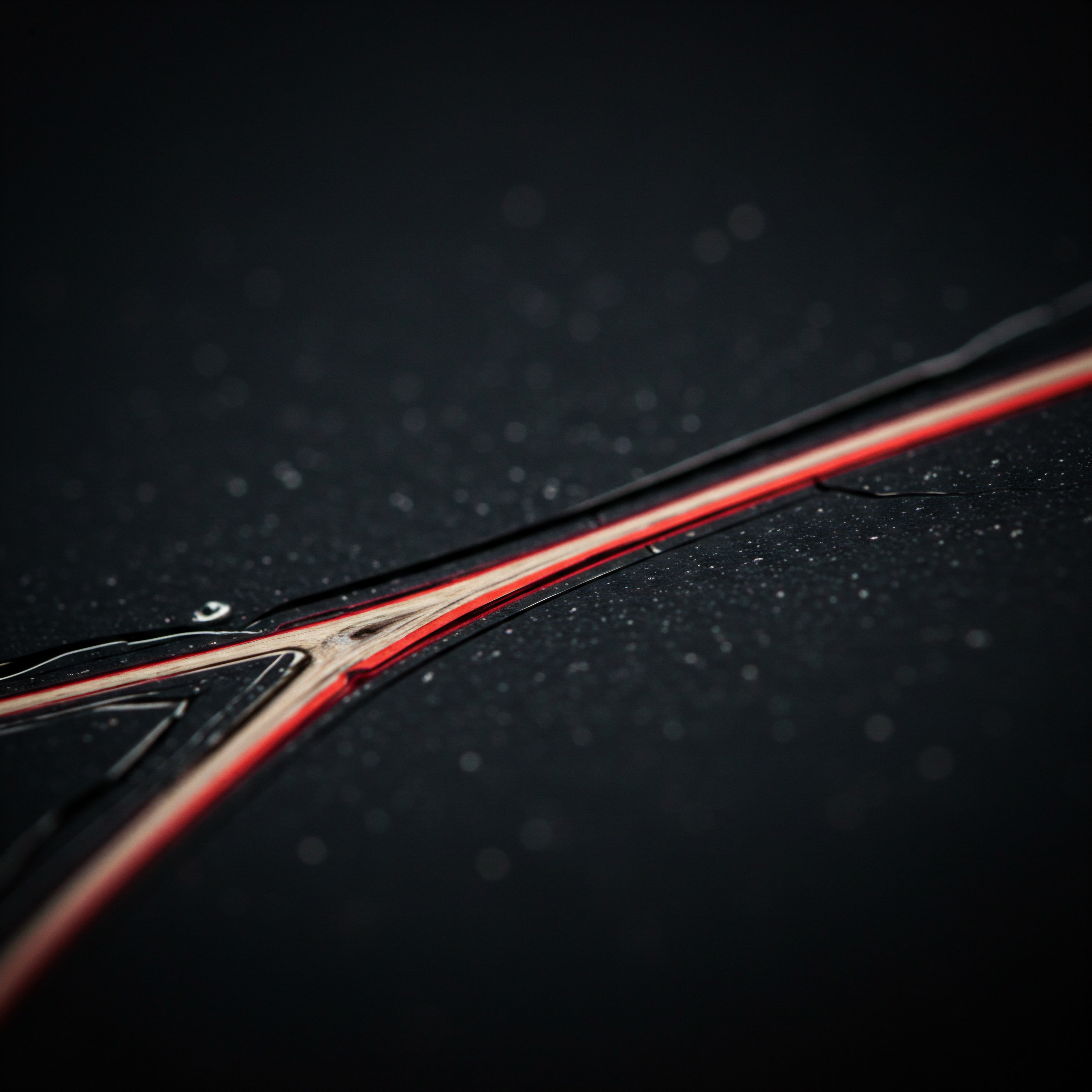

- Waste-Reducing Precision Manufacturing ● Implementing automated precision machining and cutting technologies minimizes material waste in production. For example, laser cutting systems and CNC machines can be programmed to optimize material usage, reducing scrap and the need for raw materials. This directly contributes to resource conservation and cost savings.

- Automated Recycling and Material Handling Systems ● SMBs can integrate automated systems for sorting, processing, and recycling manufacturing waste. Robotic arms and vision systems can be used to efficiently separate recyclable materials, while automated conveyors and sorting systems streamline the recycling process. This promotes circular economy principles and reduces landfill waste.

- Data-Driven Energy Management ● Utilizing industrial IoT sensors and data analytics platforms to monitor and optimize energy consumption in manufacturing facilities. Real-time data on machine energy usage, environmental conditions, and production schedules can be analyzed to identify energy-saving opportunities and implement automated energy management strategies. This leads to significant reductions in energy costs and environmental impact.

These examples demonstrate that sustainable Manufacturing Automation Strategy is not just a theoretical concept but a practical and actionable approach for SMBs to enhance their competitiveness, environmental performance, and long-term sustainability. By embracing a holistic and ethically informed approach to automation, SMBs can unlock significant benefits for their businesses, their communities, and the planet.

| Level Fundamentals |

| Focus Task Replacement |

| Objectives Efficiency in specific processes, cost reduction |

| Technology Emphasis Basic process automation, simple robotics |

| Strategic Impact Operational improvements |

| Sustainability Consideration Minimal |

| Level Intermediate |

| Focus Process Optimization & Integration |

| Objectives Value stream efficiency, quality, flexibility, responsiveness |

| Technology Emphasis Advanced robotics, machine vision, industrial IoT |

| Strategic Impact Competitive advantage, market differentiation |

| Sustainability Consideration Moderate, emerging awareness |

| Level Advanced (Sustainable) |

| Focus Strategic Transformation & Societal Value |

| Objectives Triple bottom line (economic, environmental, social), long-term sustainability, circular economy |

| Technology Emphasis AI, advanced analytics, green technologies, circular economy enabling automation |

| Strategic Impact Systemic change, industry leadership, societal impact |

| Sustainability Consideration Central and integral |

| Category Environmental |

| KPI Carbon Footprint Reduction |

| Description Decrease in greenhouse gas emissions from manufacturing operations. |

| Measurement Tons of CO2 equivalent reduced annually. |

| Category Waste Reduction Rate |

| KPI Percentage decrease in manufacturing waste sent to landfill. |

| Description Percentage reduction in waste volume or weight. |

| Category Energy Efficiency Improvement |

| KPI Percentage increase in energy efficiency of manufacturing processes. |

| Description Percentage reduction in energy consumption per unit of output. |

| Category Social |

| KPI Employee Upskilling Rate |

| Description Percentage of employees participating in automation-related training programs. |

| Measurement Percentage of employees trained annually. |

| Category Community Engagement Score |

| KPI Level of SMB involvement in local community sustainability initiatives. |

| Description Qualitative assessment based on participation and impact. |

| Category Economic |

| KPI Sustainable ROI |

| Description Return on investment specifically from sustainable automation initiatives. |

| Measurement Percentage return on sustainable automation investments. |

| Category Green Revenue Growth |

| KPI Revenue generated from eco-friendly products or services enabled by automation. |

| Description Percentage increase in revenue from sustainable offerings. |

| Technology Energy-Efficient Robots |

| Sustainable Application Reduced energy consumption in material handling and assembly. |

| SMB Benefit Lower operational costs, reduced carbon footprint. |

| Technology Precision Machining (CNC, Laser) |

| Sustainable Application Minimized material waste through optimized cutting and shaping. |

| SMB Benefit Reduced material costs, resource conservation. |

| Technology Machine Vision Systems |

| Sustainable Application Improved quality control, reduced defects, minimized rework and waste. |

| SMB Benefit Enhanced product quality, reduced waste, cost savings. |

| Technology Industrial IoT & Data Analytics |

| Sustainable Application Real-time energy monitoring, predictive maintenance, optimized resource utilization. |

| SMB Benefit Energy cost reduction, improved machine uptime, resource efficiency. |

| Technology Automated Recycling Systems |

| Sustainable Application Efficient sorting and processing of manufacturing waste for recycling. |

| SMB Benefit Reduced landfill waste, circular economy contribution, potential revenue from recycled materials. |