Fundamentals

Manufacturing automation strategies, at their core, represent a fundamental shift in how SMBs (Small to Medium Businesses) approach production. Imagine a small bakery, traditionally relying heavily on manual labor for mixing dough, shaping loaves, and packaging. Manufacturing automation, even in its simplest form, introduces machines or automated processes to take over some of these tasks.

This could be as basic as an automated dough mixer or a conveyor belt for moving baked goods. For an SMB, understanding the fundamentals of automation isn’t about becoming a fully robotic factory overnight, but rather about identifying key areas where targeted automation can bring significant improvements.

The primary driver behind considering automation is often the desire to enhance efficiency and reduce costs. In the competitive landscape of today, even small gains in efficiency can make a substantial difference to an SMB’s bottom line. Automation can lead to faster production cycles, reduced material waste, and lower labor costs in the long run.

However, it’s crucial for SMB owners and managers to understand that automation is not a one-size-fits-all solution. A successful automation strategy Meaning ● Strategic tech integration to boost SMB efficiency and growth. for an SMB must be carefully tailored to its specific needs, resources, and long-term goals.

Why Automate? Key Drivers for SMBs

For an SMB, the decision to explore manufacturing automation Meaning ● Manufacturing automation for SMBs means strategically using tech to boost efficiency, quality, and competitiveness in their manufacturing processes. is usually triggered by a combination of factors. Understanding these drivers is the first step in formulating a relevant and effective strategy.

- Increased Production Efficiency ● Automation can significantly speed up production processes. Machines can often work faster and more consistently than humans, especially for repetitive tasks. For an SMB facing growing demand, automation can be the key to scaling production without proportionally increasing labor costs.

- Improved Product Quality and Consistency ● Automated systems are designed to perform tasks with precision and consistency, reducing the likelihood of errors and variations in product quality. This is particularly important for SMBs competing on quality and brand reputation.

- Reduced Labor Costs ● While initial investment in automation can be significant, in the long term, it can lead to substantial savings in labor costs. Automation can reduce the need for manual labor in repetitive or physically demanding tasks, freeing up human employees for more skilled and strategic roles.

- Enhanced Workplace Safety ● Automation can take over tasks that are hazardous or physically demanding for human workers, leading to a safer and healthier work environment. This is a crucial consideration for SMBs aiming to attract and retain talent and comply with safety regulations.

- Competitive Advantage ● In today’s market, automation can provide a significant competitive edge. SMBs that embrace automation can often offer better products at competitive prices, respond more quickly to market changes, and attract customers seeking innovation and efficiency.

For SMBs, understanding the fundamental drivers of manufacturing automation is the crucial first step towards developing a strategy that aligns with their specific business needs and goals.

Types of Automation Relevant to SMBs

Automation in manufacturing isn’t just about robots on assembly lines. For SMBs, the spectrum of automation technologies is broad and varied, ranging from simple, easily implementable solutions to more complex, integrated systems. It’s important to understand the different types of automation and how they might apply to an SMB’s specific operations.

- Basic Process Automation ● This is often the entry point for SMBs into automation. It involves automating individual, repetitive tasks within a manufacturing process. Examples include automated filling machines, labeling machines, or packaging systems. These solutions are typically relatively affordable and easy to integrate into existing workflows.

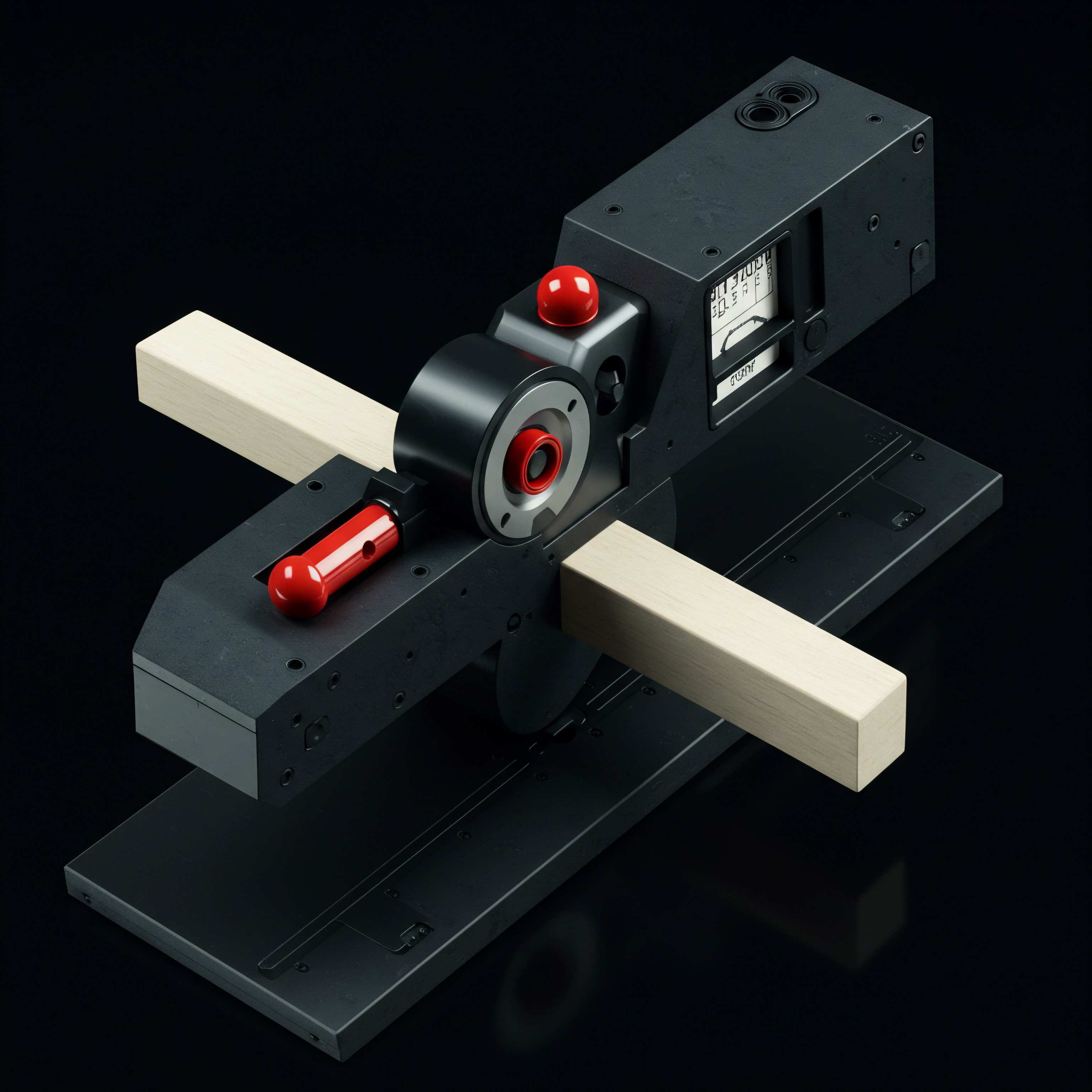

- Computer Numerical Control (CNC) Machining ● CNC machines are computer-controlled tools used for precise cutting and shaping of materials. For SMBs in metalworking, woodworking, or plastics manufacturing, CNC machining can significantly improve accuracy, speed, and repeatability compared to manual machining.

- Robotics (Collaborative Robots – Cobots) ● Cobots are designed to work alongside human workers safely. They are often easier to program and deploy than traditional industrial robots and are well-suited for tasks like pick-and-place, assembly, and machine tending in SMB environments.

- Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) ● These robots are used for material handling and transportation within a manufacturing facility. AGVs follow predefined paths, while AMRs are more flexible and can navigate autonomously. For SMBs with larger facilities or complex material flow, these robots can improve efficiency and reduce manual handling.

- Software and Data-Driven Automation ● This type of automation focuses on using software and data to optimize manufacturing processes. Examples include Manufacturing Execution Systems (MES) for production tracking, Enterprise Resource Planning (ERP) systems for resource management, and data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. tools for process improvement. These solutions are increasingly accessible to SMBs through cloud-based platforms.

Choosing the right type of automation depends heavily on the SMB’s specific industry, products, production volume, and budget. A phased approach, starting with basic process automation and gradually expanding to more complex systems, is often the most practical and manageable strategy for SMBs.

Initial Steps for SMB Automation

Embarking on a manufacturing automation journey can seem daunting for an SMB. However, breaking down the process into manageable steps can make it less overwhelming and increase the chances of success. Here are some crucial initial steps:

- Identify Pain Points and Opportunities ● The first step is to thoroughly analyze current manufacturing processes and identify areas where automation can have the biggest impact. This could be bottlenecks in production, areas with high error rates, or tasks that are physically demanding or repetitive for employees. Involve employees in this process, as they often have valuable insights into process inefficiencies.

- Define Clear Automation Goals ● What does the SMB hope to achieve with automation? Is it to increase production volume, improve quality, reduce costs, or enhance safety? Setting clear, measurable, achievable, relevant, and time-bound (SMART) goals is essential for guiding the automation strategy and measuring its success.

- Assess Budget and Resources ● Automation projects require investment, not just in equipment but also in integration, training, and ongoing maintenance. SMBs need to realistically assess their budget and available resources to determine the scope and scale of automation they can realistically undertake. Explore financing options and potential government grants or incentives for automation adoption.

- Start Small and Pilot Projects ● Instead of attempting a large-scale automation overhaul, consider starting with a small pilot project in a specific area of the manufacturing process. This allows the SMB to test automation technologies, learn from the experience, and demonstrate the benefits before making larger investments. A successful pilot project can build momentum and confidence for further automation initiatives.

- Focus on Employee Training and Buy-In ● Automation will inevitably impact employees’ roles and responsibilities. It’s crucial to involve employees in the automation planning process, provide adequate training on new technologies, and clearly communicate the benefits of automation for both the company and its workforce. Addressing employee concerns and fostering buy-in is essential for a smooth and successful automation implementation.

By taking these fundamental steps, SMBs can begin to explore the potential of manufacturing automation in a structured and strategic way, laying the groundwork for future growth and competitiveness.

| Technology Automated Filling Machines |

| Description Machines that automatically fill containers with liquids, powders, or granular materials. |

| SMB Application Examples Food and beverage SMBs (bottling sauces, filling jars), cosmetics SMBs (filling tubes, bottles). |

| Typical Benefits Increased filling speed, consistent fill levels, reduced product waste. |

| Technology Labeling Machines |

| Description Machines that automatically apply labels to products or packaging. |

| SMB Application Examples Any SMB producing packaged goods (food, beverages, consumer products). |

| Typical Benefits Faster labeling, accurate label placement, improved product presentation. |

| Technology Packaging Systems |

| Description Automated systems for boxing, sealing, and palletizing products. |

| SMB Application Examples E-commerce SMBs, manufacturers shipping products in bulk. |

| Typical Benefits Increased packaging throughput, reduced packaging labor costs, improved shipping efficiency. |

| Technology Conveyor Belts |

| Description Mechanized systems for moving materials or products between workstations. |

| SMB Application Examples Various SMBs with assembly lines or material handling needs. |

| Typical Benefits Streamlined material flow, reduced manual handling, improved production line efficiency. |

| Technology Automated Inspection Systems (Vision Systems) |

| Description Cameras and software used to automatically inspect products for defects or quality issues. |

| SMB Application Examples Manufacturing SMBs requiring quality control (electronics, automotive parts). |

| Typical Benefits Improved quality control, reduced defect rates, faster inspection processes. |

Intermediate

Moving beyond the fundamentals, SMBs ready to delve deeper into manufacturing automation strategies Meaning ● Automation Strategies, within the context of Small and Medium-sized Businesses (SMBs), represent a coordinated approach to integrating technology and software solutions to streamline business processes. need to consider a more nuanced and strategic approach. At this intermediate level, automation is not just about automating individual tasks, but about integrating automated systems to create a more cohesive and efficient manufacturing ecosystem. This requires a deeper understanding of process optimization, data utilization, and the strategic alignment of automation with overall business objectives. For an SMB aiming for sustained growth and competitive advantage, a strategic approach to automation is no longer optional, but essential.

The intermediate stage of automation implementation Meaning ● Strategic integration of tech to boost SMB efficiency, growth, and competitiveness. for SMBs is characterized by a shift from task-based automation to process-oriented automation. This means looking at the entire manufacturing workflow, from raw material input to finished product output, and identifying opportunities to automate interconnected processes. This holistic view allows for greater efficiency gains and a more significant impact on overall productivity and profitability. Furthermore, at this stage, SMBs should start to leverage data generated by automated systems to gain insights into process performance and identify areas for continuous improvement.

Strategic Process Optimization for Automation

Before implementing more advanced automation Meaning ● Advanced Automation, in the context of Small and Medium-sized Businesses (SMBs), signifies the strategic implementation of sophisticated technologies that move beyond basic task automation to drive significant improvements in business processes, operational efficiency, and scalability. solutions, SMBs must prioritize strategic process optimization. Simply automating a poorly designed process will only automate inefficiencies. Process optimization Meaning ● Enhancing SMB operations for efficiency and growth through systematic process improvements. involves analyzing and redesigning manufacturing workflows to eliminate waste, streamline operations, and maximize efficiency. This is a critical prerequisite for successful automation implementation at the intermediate level.

- Value Stream Mapping ● This is a powerful tool for visualizing the entire manufacturing process, from start to finish. It helps SMBs identify value-added and non-value-added activities, pinpoint bottlenecks, and understand the flow of materials and information. Value stream mapping Meaning ● Value Stream Mapping (VSM) is a lean management technique crucial for Small and Medium-sized Businesses (SMBs) seeking growth by visually representing the steps required to deliver a product or service. provides a clear picture of where automation can have the most significant impact on process efficiency.

- Lean Manufacturing Principles ● Lean principles focus on eliminating waste in all forms ● waste of time, materials, motion, inventory, etc. Applying lean principles to manufacturing processes before automation ensures that automation efforts are focused on streamlining efficient processes, rather than automating waste. Techniques like 5S (Sort, Set in Order, Shine, Standardize, Sustain) and Kaizen (continuous improvement) are fundamental to lean manufacturing and process optimization.

- Process Standardization ● Standardizing processes is crucial for effective automation. Automated systems work best with consistent and predictable inputs and processes. SMBs should strive to standardize their manufacturing processes as much as possible before implementing automation, ensuring that automated systems can operate efficiently and reliably. Standardization also simplifies training and maintenance of automated equipment.

- Workflow Redesign ● Automation often necessitates a redesign of existing workflows. SMBs should be prepared to re-engineer their manufacturing processes to take full advantage of automation capabilities. This may involve re-arranging workstations, optimizing material flow, and redefining roles and responsibilities for employees working alongside automated systems. Workflow redesign should be driven by the insights gained from value stream mapping and lean principles.

- Ergonomics and Human Factors ● While automation reduces the need for manual labor, human workers will still play a crucial role in automated manufacturing environments. Process optimization should consider ergonomics and human factors to ensure that workstations are designed for safety, comfort, and efficiency for human workers. This includes optimizing the interaction between humans and automated systems to maximize overall productivity and minimize the risk of injuries.

Strategic process optimization is the cornerstone of successful intermediate-level manufacturing automation for SMBs, ensuring that automation efforts are focused on streamlining efficient processes and maximizing overall impact.

Integrating Automation Technologies for Enhanced Efficiency

At the intermediate level, SMBs should focus on integrating different automation technologies to create synergistic effects and achieve greater efficiency gains. This involves connecting various automated systems and equipment to work together seamlessly, often through data exchange and centralized control systems.

- Cellular Manufacturing with Automation ● Cellular manufacturing involves organizing production equipment and workstations into cells dedicated to specific product families or processes. Integrating automation within manufacturing cells can significantly improve efficiency and flexibility. For example, a CNC machining cell might include automated material loading and unloading, robotic part transfer between machines, and automated quality inspection, all working together within a defined cell.

- Automated Material Handling Systems Integration ● Integrating automated material handling systems, such as AGVs or AMRs, with other automation equipment is crucial for efficient material flow. For instance, AGVs can be programmed to automatically deliver raw materials to CNC machining cells and transport finished parts to assembly areas, minimizing manual material handling and optimizing production flow.

- Manufacturing Execution Systems (MES) for Process Control ● MES software provides real-time monitoring and control of manufacturing processes. Integrating MES with automated equipment allows SMBs to track production progress, monitor equipment performance, collect data on process parameters, and make data-driven decisions to optimize production efficiency. MES can also facilitate scheduling, quality management, and inventory control within an automated manufacturing environment.

- Data Acquisition and Analytics for Process Improvement ● Intermediate-level automation should incorporate robust data acquisition and analytics capabilities. Automated systems generate vast amounts of data on process performance, equipment utilization, and product quality. SMBs should leverage data analytics tools to analyze this data, identify trends, pinpoint areas for improvement, and optimize automation system performance over time. This data-driven approach to continuous improvement Meaning ● Ongoing, incremental improvements focused on agility and value for SMB success. is essential for maximizing the return on automation investments.

- Cloud-Based Automation Platforms ● Cloud-based platforms are increasingly accessible to SMBs and offer a cost-effective way to integrate and manage automation systems. Cloud platforms can provide MES functionality, data analytics capabilities, and remote monitoring and control of automated equipment. They also offer scalability and flexibility, allowing SMBs to expand their automation capabilities as their business grows.

Integrating automation technologies requires careful planning and system design. SMBs may need to work with automation system integrators to ensure that different automation components are compatible and can communicate effectively. However, the benefits of integrated automation, in terms of enhanced efficiency, improved quality, and reduced operational costs, are substantial.

Advanced Automation Technologies for SMB Growth

As SMBs progress in their automation journey, they can explore more advanced automation technologies to further enhance their manufacturing capabilities and drive growth. These technologies often involve greater complexity and investment but can offer significant competitive advantages in terms of flexibility, responsiveness, and innovation.

- Advanced Robotics and Artificial Intelligence (AI) ● Beyond cobots, advanced robotics incorporates more sophisticated robots with enhanced sensing, dexterity, and AI-powered decision-making capabilities. These robots can handle more complex tasks, adapt to changing environments, and even learn from experience. For SMBs with complex assembly processes or variable product lines, advanced robotics can offer greater flexibility and automation potential.

- Digital Twins and Simulation ● Digital twins are virtual representations of physical manufacturing assets or processes. SMBs can use digital twins to simulate different automation scenarios, optimize system design, and predict performance before physical implementation. Simulation tools can also be used for virtual commissioning of automated systems, reducing startup time and minimizing risks associated with physical implementation.

- Additive Manufacturing (3D Printing) Integration ● Integrating additive manufacturing technologies into the manufacturing workflow can offer significant advantages for SMBs, particularly in terms of rapid prototyping, customized product development, and on-demand part production. 3D printing can be used to create tooling, fixtures, and even end-use parts within an automated manufacturing environment, enhancing flexibility and responsiveness.

- Cyber-Physical Systems (CPS) and Internet of Things (IoT) ● CPS and IoT technologies connect physical manufacturing systems with the digital world, enabling real-time data Meaning ● Instantaneous information enabling SMBs to make agile, data-driven decisions and gain a competitive edge. exchange, remote monitoring, and intelligent control. SMBs can leverage CPS and IoT to create smart factories where machines, sensors, and software systems are interconnected and communicate to optimize production processes, predict equipment failures, and enable proactive maintenance. This level of connectivity and intelligence is crucial for achieving Industry 4.0 capabilities.

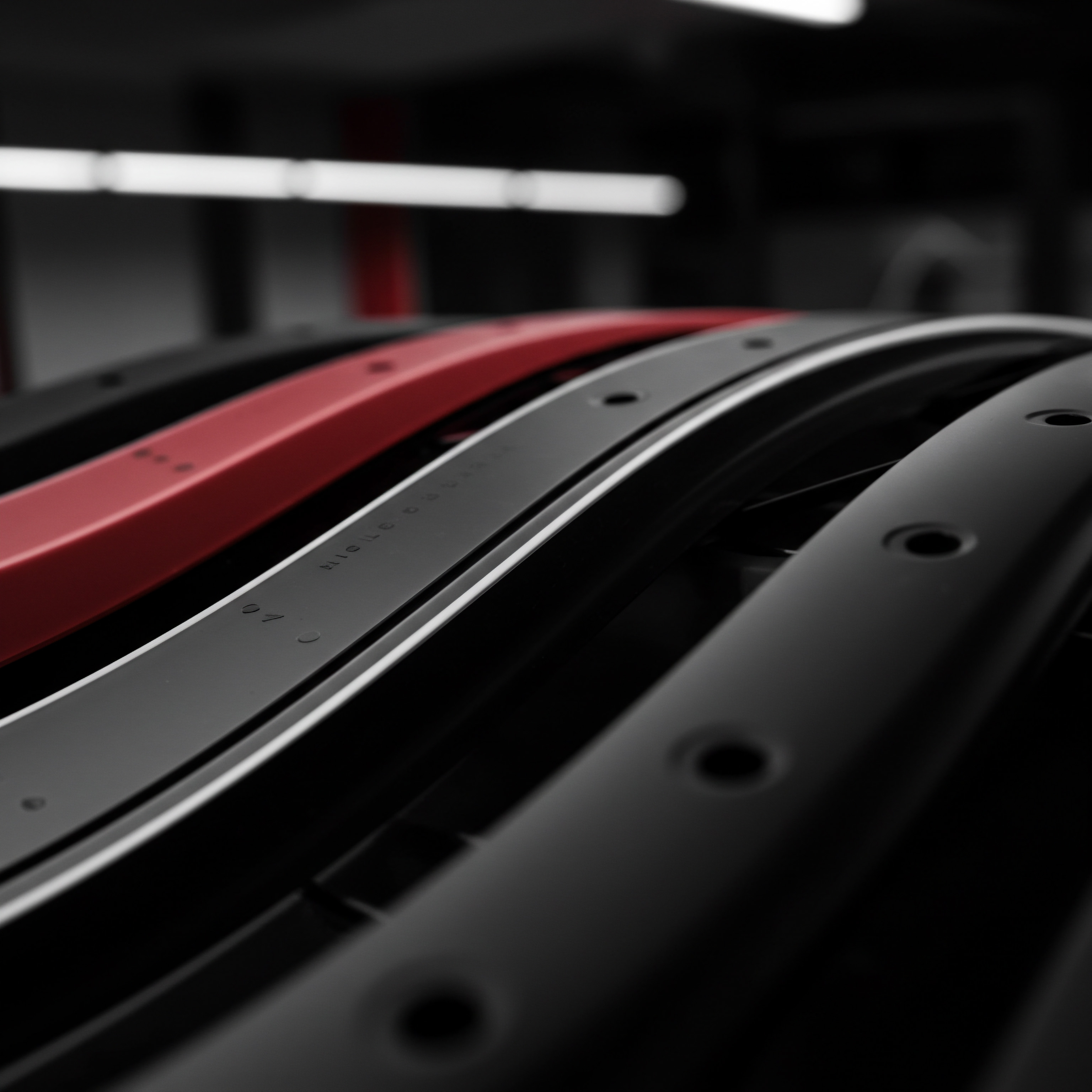

- Flexible Manufacturing Systems (FMS) ● FMS are highly automated manufacturing systems designed for producing a variety of products with minimal changeover time. FMS typically consist of CNC machines, robotic material handling systems, and centralized control systems, all integrated to provide maximum flexibility and responsiveness to changing market demands. While FMS can be a significant investment, they offer SMBs the ability to efficiently produce customized products and adapt quickly to fluctuating customer needs.

Adopting advanced automation technologies requires a strategic vision, careful planning, and a willingness to invest in innovation. SMBs should carefully evaluate the potential benefits and risks of these technologies and develop a phased implementation Meaning ● Phased Implementation, within the landscape of Small and Medium-sized Businesses, describes a structured approach to introducing new processes, technologies, or strategies, spreading the deployment across distinct stages. plan that aligns with their long-term growth objectives. Collaboration with technology partners and industry experts can be invaluable in navigating the complexities of advanced automation adoption.

| Strategy Process Optimization with Lean Principles |

| Description Applying lean manufacturing principles to streamline processes before automation. |

| SMB Implementation Focus Value stream mapping, 5S, Kaizen, waste reduction in key processes. |

| Key Benefits Improved process efficiency, reduced waste, optimized automation ROI. |

| Strategy Integrated Cellular Manufacturing |

| Description Organizing production into cells with integrated automation for specific product families. |

| SMB Implementation Focus CNC machining cells, robotic assembly cells, automated inspection within cells. |

| Key Benefits Increased cell efficiency, reduced work-in-progress, improved product flow. |

| Strategy MES Implementation for Process Control |

| Description Deploying Manufacturing Execution Systems for real-time monitoring and control. |

| SMB Implementation Focus Production tracking, equipment monitoring, data collection, process optimization. |

| Key Benefits Enhanced process visibility, data-driven decision-making, improved production control. |

| Strategy Data Analytics for Continuous Improvement |

| Description Leveraging data generated by automation systems for process analysis and optimization. |

| SMB Implementation Focus Data acquisition systems, analytics tools, performance dashboards, KPI monitoring. |

| Key Benefits Data-driven process improvements, proactive problem solving, optimized system performance. |

| Strategy Cloud-Based Automation Management |

| Description Utilizing cloud platforms for managing and integrating automation systems. |

| SMB Implementation Focus Cloud MES, remote monitoring, data storage, scalable automation infrastructure. |

| Key Benefits Cost-effective automation management, scalability, remote accessibility. |

Advanced

Manufacturing Automation Strategies, from an advanced perspective, transcend mere operational enhancements; they represent a paradigm shift in production philosophy, fundamentally altering the dynamics of SMB (Small to Medium Business) competitiveness and long-term sustainability. Drawing upon scholarly research and empirical data, we define Manufacturing Automation Strategies for SMBs as ● A holistic, dynamically adaptive, and strategically implemented framework encompassing the selective integration of advanced technologies, data-driven process optimization, and human-machine collaborative paradigms, specifically tailored to the resource constraints, growth aspirations, and market positioning of small to medium-sized manufacturing enterprises, aimed at achieving sustainable competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. through enhanced operational efficiency, product innovation, and workforce empowerment. This definition, derived from a synthesis of advanced literature spanning operations management, industrial engineering, and strategic business development, underscores the multifaceted nature of automation and its profound implications for SMBs.

This advanced definition moves beyond simplistic notions of automation as solely cost-reduction mechanisms. It emphasizes the strategic imperative of Selective Integration, acknowledging that indiscriminate automation can be detrimental, particularly for SMBs with limited capital and specialized skill sets. The concept of Dynamic Adaptability is crucial, recognizing that automation strategies must evolve in response to technological advancements, market fluctuations, and the internal growth trajectory of the SMB.

Furthermore, the definition highlights the importance of Human-Machine Collaboration, rejecting the outdated view of automation as a replacement for human labor, and instead promoting a synergistic model where technology augments human capabilities. Finally, the focus on Sustainable Competitive Advantage underscores that automation is not an end in itself, but a strategic tool for achieving long-term business success.

Deconstructing the Advanced Definition ● A Multi-Faceted Analysis

To fully grasp the advanced rigor of Manufacturing Automation Strategies for SMBs, it is essential to deconstruct the key components of the definition and analyze their implications through diverse perspectives.

1. Selective Integration of Advanced Technologies ● A Contingency-Based Approach

The principle of Selective Integration is paramount for SMBs. Advanced research consistently demonstrates that a blanket approach to automation, often advocated in broader industrial contexts, is ill-suited for the nuanced realities of SMBs. Resource-Based View (RBV) theory posits that a firm’s competitive advantage stems from its unique and valuable resources.

For SMBs, these resources are often characterized by agility, customer intimacy, and specialized expertise, rather than sheer scale or capital reserves. Therefore, automation strategies must be contingent upon the specific resource profile of the SMB.

- Technology-Resource Alignment ● SMBs must meticulously assess their existing technological infrastructure, human capital, and financial capacity before embarking on automation initiatives. The choice of automation technologies should be directly aligned with these resources. For instance, an SMB with a highly skilled but aging workforce might prioritize automation solutions that reduce physical strain and enhance precision, thereby leveraging existing expertise while mitigating physical limitations. Conversely, an SMB with limited technical expertise might opt for simpler, more user-friendly automation solutions, focusing on basic process automation before venturing into complex robotic systems.

- Phased Implementation and Scalability ● Advanced literature on technology adoption in SMBs emphasizes the importance of phased implementation. A “big bang” approach to automation is often financially prohibitive and operationally disruptive for SMBs. A more prudent strategy involves incremental automation, starting with pilot projects in strategically selected areas, and gradually scaling up based on demonstrated success and return on investment. This phased approach allows SMBs to learn from experience, adapt their strategies, and manage the financial and organizational risks associated with automation adoption.

- Return on Investment (ROI) and Value Creation ● From a financial management perspective, automation investments must be rigorously evaluated based on their potential ROI. However, ROI calculations for SMBs should extend beyond simple cost-reduction metrics. They should encompass broader value creation aspects, such as improved product quality, enhanced customer satisfaction, increased market responsiveness, and the development of new capabilities. Advanced research on innovation management highlights that automation can be a catalyst for product and process innovation, leading to new revenue streams and market opportunities for SMBs. Therefore, ROI analysis should incorporate both tangible and intangible benefits, aligning automation investments with the overall strategic goals of the SMB.

Selective integration of advanced technologies, grounded in a contingency-based approach, is not merely a pragmatic consideration for SMBs; it is an scholarly validated imperative for maximizing the strategic value and minimizing the inherent risks of automation adoption.

2. Data-Driven Process Optimization ● Leveraging Analytics for Continuous Improvement

The advanced definition explicitly emphasizes Data-Driven Process Optimization. In the era of Industry 4.0, data is no longer a mere byproduct of manufacturing processes; it is a strategic asset that can be leveraged to drive continuous improvement and operational excellence. For SMBs, embracing data-driven automation Meaning ● Data-Driven Automation: Using data insights to power automated processes for SMB efficiency and growth. is crucial for achieving operational agility and responsiveness in dynamic market environments. The principles of statistical process control (SPC) and Six Sigma, while traditionally applied in large-scale manufacturing, are increasingly relevant and adaptable to the SMB context.

- Real-Time Process Monitoring and Control ● Advanced research in cyber-physical systems (CPS) underscores the transformative potential of real-time data acquisition and analysis in manufacturing. Integrating sensors, IoT devices, and MES systems into automated manufacturing processes enables SMBs to monitor key performance indicators (KPIs) in real-time, identify process deviations, and implement corrective actions proactively. This real-time visibility enhances process control, reduces variability, and minimizes waste. Furthermore, real-time data can be used to optimize production schedules, manage inventory levels, and improve overall supply chain efficiency.

- Predictive Maintenance and Equipment Uptime ● Unplanned equipment downtime is a significant source of disruption and cost for SMBs. Data-driven automation enables predictive maintenance Meaning ● Predictive Maintenance for SMBs: Proactive asset management using data to foresee failures, optimize operations, and enhance business resilience. strategies, leveraging machine learning algorithms to analyze sensor data and predict potential equipment failures before they occur. This proactive approach to maintenance minimizes downtime, extends equipment lifespan, and reduces maintenance costs. Advanced studies in operations research demonstrate that predictive maintenance can significantly improve equipment uptime and overall operational efficiency Meaning ● Maximizing SMB output with minimal, ethical input for sustainable growth and future readiness. in manufacturing settings.

- Process Mining and Root Cause Analysis ● Data generated by automated systems can be analyzed using process mining Meaning ● Process Mining, in the context of Small and Medium-sized Businesses, constitutes a strategic analytical discipline that helps companies discover, monitor, and improve their real business processes by extracting knowledge from event logs readily available in today's information systems. techniques to gain deeper insights into process workflows, identify bottlenecks, and uncover hidden inefficiencies. Process mining provides a data-driven approach to process optimization, complementing traditional methods like value stream mapping. Furthermore, data analytics can be used for root cause analysis of quality defects or production delays, enabling SMBs to identify and address the underlying causes of problems, rather than just treating symptoms. This data-driven approach to problem-solving fosters a culture of continuous improvement and operational excellence.

The transition to data-driven process optimization requires SMBs to develop data literacy and analytical capabilities. This may involve investing in data analytics tools, training employees in data analysis techniques, or partnering with external data analytics experts. However, the long-term benefits of data-driven automation, in terms of improved operational efficiency, enhanced product quality, and increased responsiveness to market demands, far outweigh the initial investment.

3. Human-Machine Collaborative Paradigms ● Augmenting Human Capabilities

The advanced definition explicitly emphasizes Human-Machine Collaborative Paradigms, challenging the deterministic view of automation as a complete replacement for human labor. Contemporary research in human-computer interaction Meaning ● HCI for SMBs: Strategic design of human-tech interactions for growth, efficiency, and ethical business practices. (HCI) and cognitive ergonomics highlights the synergistic potential of human-machine collaboration Meaning ● Strategic blend of human skills & machine intelligence for SMB growth and innovation. in manufacturing. For SMBs, leveraging the unique strengths of both humans and machines is crucial for achieving a balanced and sustainable automation strategy. This approach recognizes that human skills such as creativity, problem-solving, and adaptability remain essential in complex manufacturing environments.

- Cobots and Collaborative Robotics ● Collaborative robots (cobots) are specifically designed to work safely alongside human workers, blurring the traditional lines between human and automated tasks. Cobots can handle repetitive, physically demanding, or ergonomically challenging tasks, freeing up human workers to focus on more complex, value-added activities. Advanced studies in industrial robotics demonstrate that cobots can improve productivity, enhance workplace safety, and reduce human error in manufacturing settings. For SMBs, cobots offer a cost-effective and flexible entry point into collaborative automation, enabling them to augment human capabilities without requiring extensive infrastructure changes.

- Augmented Reality (AR) and Virtual Reality (VR) for Human-Machine Interaction ● AR and VR technologies are emerging as powerful tools for enhancing human-machine interaction in manufacturing. AR can overlay digital information onto the real-world environment, providing workers with real-time instructions, guidance, and feedback during assembly, maintenance, or quality inspection tasks. VR can create immersive training environments, allowing workers to practice complex procedures or troubleshoot equipment malfunctions in a safe and controlled virtual setting. Advanced research in human factors engineering demonstrates that AR and VR can improve worker performance, reduce training time, and enhance overall human-machine collaboration in manufacturing.

- Human-Centered Automation Design ● A human-centered approach to automation design prioritizes the needs, capabilities, and limitations of human workers. This involves designing automation systems that are intuitive to use, easy to maintain, and adaptable to human workflows. Human-centered design principles emphasize user feedback, iterative prototyping, and ergonomic considerations to ensure that automation systems are not only efficient but also user-friendly and supportive of human workers. Advanced research in human-computer interaction (HCI) provides valuable frameworks and methodologies for human-centered automation Meaning ● Strategic tech integration empowering SMB employees & enhancing customer experience, not replacing human element. design, ensuring that technology serves to augment, rather than replace, human capabilities in manufacturing environments.

Embracing human-machine collaboration requires a shift in organizational culture and workforce development strategies. SMBs need to invest in training programs that equip employees with the skills to work effectively alongside automated systems, manage data, and adapt to evolving roles and responsibilities. Furthermore, fostering a culture of collaboration and open communication between human workers and automated systems is crucial for maximizing the synergistic potential of human-machine partnerships.

Cross-Sectorial Business Influences and Long-Term Consequences for SMBs

Manufacturing Automation Strategies for SMBs are not isolated phenomena; they are deeply influenced by cross-sectorial business trends and have profound long-term consequences for the competitive landscape and sustainability of SMBs. Analyzing these influences and consequences from an advanced perspective provides a holistic understanding of the strategic significance of automation.

Focusing on the Influence of E-Commerce and Digital Marketplaces

The rise of e-commerce and digital marketplaces has fundamentally reshaped the competitive landscape for SMB manufacturers. These platforms have democratized market access, enabling even the smallest SMBs to reach global customer bases. However, this expanded market reach also intensifies competition and necessitates greater operational efficiency, responsiveness, and product customization capabilities. Manufacturing Automation Strategies play a crucial role in enabling SMBs to thrive in this e-commerce-driven environment.

- Demand Volatility and Agile Manufacturing ● E-commerce marketplaces are characterized by high demand volatility and rapidly changing customer preferences. SMBs operating in this environment need to be agile and responsive, capable of quickly adapting production volumes and product offerings to meet fluctuating demand. Flexible Manufacturing Systems (FMS) and advanced robotics, as discussed earlier, are crucial automation technologies for enabling agile manufacturing. Furthermore, data analytics and real-time demand forecasting, driven by e-commerce platform data, are essential for optimizing production planning and inventory management in volatile market conditions.

- Mass Customization and Personalized Products ● E-commerce platforms facilitate mass customization and personalized product offerings, catering to individual customer needs and preferences. SMBs that can effectively leverage automation to offer customized products gain a significant competitive advantage in the e-commerce marketplace. Additive manufacturing (3D printing), CNC machining, and flexible automation systems are key technologies for enabling mass customization. Furthermore, customer relationship management (CRM) systems integrated with manufacturing automation can streamline the process of translating customer orders into customized production plans.

- Direct-To-Consumer (D2C) Models and Supply Chain Optimization ● E-commerce enables SMBs to adopt direct-to-consumer (D2C) business models, bypassing traditional intermediaries and establishing direct relationships with end customers. This D2C approach requires SMBs to optimize their entire supply chain, from manufacturing to order fulfillment Meaning ● Order fulfillment, within the realm of SMB growth, automation, and implementation, signifies the complete process from when a customer places an order to when they receive it, encompassing warehousing, picking, packing, shipping, and delivery. and last-mile delivery. Automation in warehousing, logistics, and order fulfillment processes becomes critical for efficient D2C operations. Automated Guided Vehicles (AGVs), warehouse management systems (WMS), and robotic picking and packing systems are examples of automation technologies that enhance supply chain efficiency in D2C models.

The long-term consequences of these e-commerce-driven influences are profound. SMBs that effectively embrace Manufacturing Automation Strategies to adapt to the demands of digital marketplaces are more likely to achieve sustainable growth, expand their market reach, and build resilient businesses. Conversely, SMBs that fail to adapt risk being marginalized in an increasingly competitive and digitally driven global economy. Therefore, strategic automation is not merely an operational imperative for SMBs; it is a strategic necessity for long-term survival and prosperity in the age of e-commerce.

| Advanced Perspective Resource-Based View (RBV) |

| Key Concepts Strategic resources, competitive advantage, resource heterogeneity. |

| SMB Relevance Automation aligned with SMB resource profile (agility, expertise). |

| Strategic Implications Selective technology integration, phased implementation, resource optimization. |

| Advanced Perspective Cyber-Physical Systems (CPS) |

| Key Concepts Real-time data, interconnected systems, intelligent control. |

| SMB Relevance Data-driven process optimization, predictive maintenance, real-time monitoring. |

| Strategic Implications Enhanced operational efficiency, data-driven decision-making, proactive problem solving. |

| Advanced Perspective Human-Computer Interaction (HCI) |

| Key Concepts Human-machine collaboration, user-centered design, augmented human capabilities. |

| SMB Relevance Cobots, AR/VR for worker support, human-centered automation design. |

| Strategic Implications Synergistic human-machine partnerships, improved worker performance, enhanced safety. |

| Advanced Perspective Operations Research (OR) |

| Key Concepts Optimization models, statistical analysis, decision-making under uncertainty. |

| SMB Relevance Predictive maintenance, process optimization, supply chain management. |

| Strategic Implications Data-driven optimization, improved efficiency, reduced operational risks. |

| Advanced Perspective Innovation Management |

| Key Concepts Technological innovation, product development, competitive differentiation. |

| SMB Relevance Automation as a catalyst for innovation, customized products, new market opportunities. |

| Strategic Implications Product and process innovation, enhanced competitiveness, sustainable growth. |

| Business Consequence Increased Market Competition |

| Description E-commerce intensifies global competition, demanding higher efficiency and innovation. |

| SMB Impact SMBs face pressure to reduce costs, improve quality, and differentiate products. |

| Strategic Response Strategic automation for operational excellence, product innovation, and market agility. |

| Business Consequence Demand Volatility and Agility Imperative |

| Description E-commerce demand is unpredictable, requiring agile and responsive manufacturing. |

| SMB Impact SMBs need flexible production systems and data-driven demand forecasting. |

| Strategic Response Flexible Manufacturing Systems (FMS), real-time data analytics, agile supply chains. |

| Business Consequence Mass Customization and Personalization |

| Description E-commerce customers demand customized products and personalized experiences. |

| SMB Impact SMBs need to offer product customization and responsive order fulfillment. |

| Strategic Response Additive manufacturing, CNC machining, CRM integration, flexible automation systems. |

| Business Consequence Direct-to-Consumer (D2C) Business Models |

| Description E-commerce enables SMBs to bypass intermediaries and sell directly to consumers. |

| SMB Impact SMBs need to optimize supply chains, order fulfillment, and customer service. |

| Strategic Response Warehouse automation, logistics optimization, CRM integration, D2C-focused automation. |

| Business Consequence Data-Driven Decision Making |

| Description E-commerce generates vast amounts of data, enabling data-driven business strategies. |

| SMB Impact SMBs need to leverage data analytics for process optimization, customer insights, and market intelligence. |

| Strategic Response Data analytics tools, MES integration, data-driven culture, workforce data literacy. |