Fundamentals

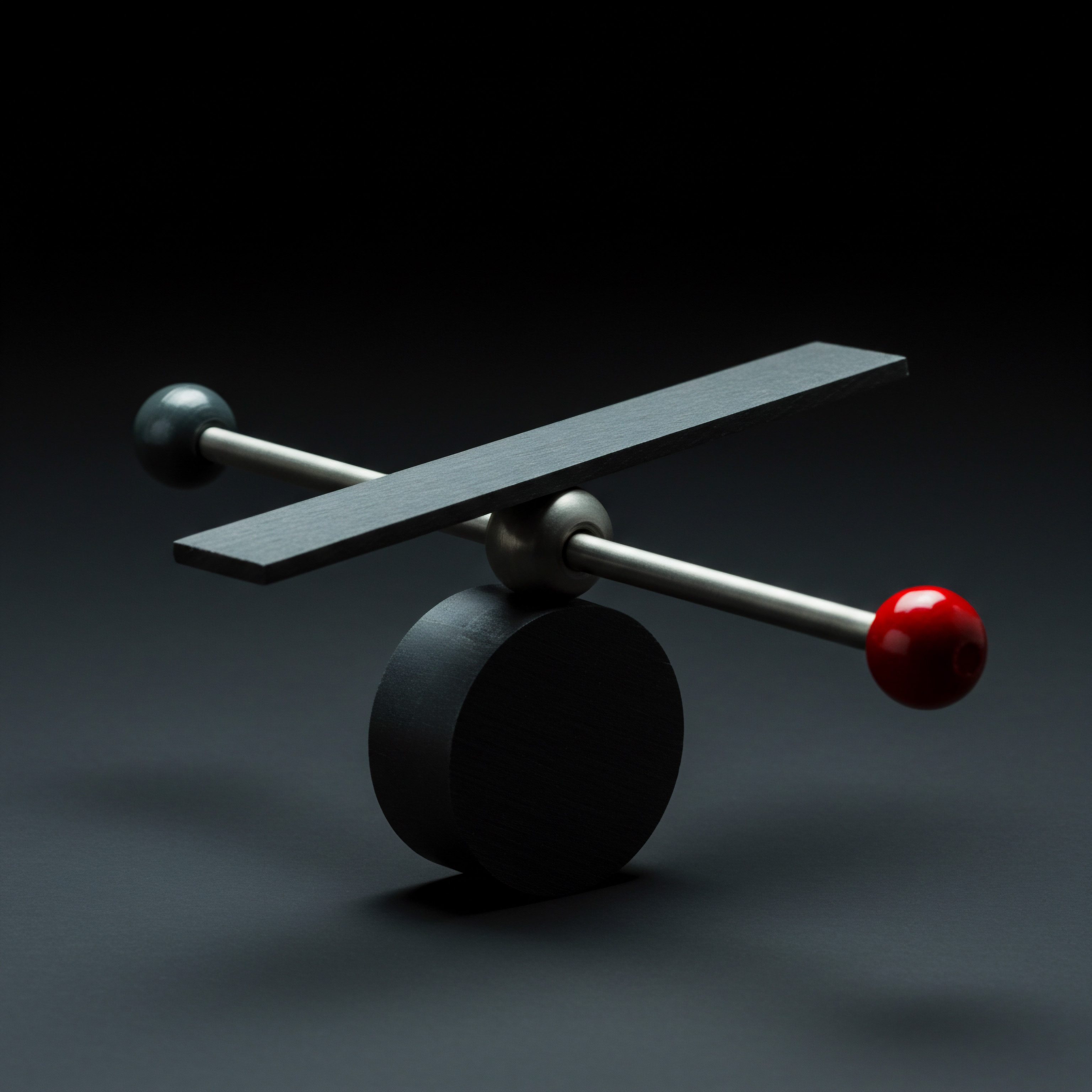

For Small to Medium-sized Businesses (SMBs), the concept of a Lean Ecosystem Implementation might initially seem like a complex undertaking reserved for large corporations. However, at its core, it’s a surprisingly straightforward and highly beneficial approach, especially for businesses aiming for sustainable growth Meaning ● Sustainable SMB growth is balanced expansion, mitigating risks, valuing stakeholders, and leveraging automation for long-term resilience and positive impact. and operational efficiency. Imagine a garden where every plant, every insect, every drop of water, and every ray of sunlight works in harmony to create a thriving environment.

A Lean Ecosystem in business operates on a similar principle, focusing on creating a synergistic and efficient system where all parts ● processes, people, technology, and resources ● work together to maximize value and minimize waste. For an SMB, this translates to doing more with less, becoming more agile, and ultimately, more competitive in the marketplace.

Let’s break down the fundamental components of Lean Ecosystem Implementation in a way that’s easily digestible for any SMB owner or manager, regardless of their prior experience with lean methodologies. Think of it as building blocks, each essential for constructing a robust and efficient business operation. We’ll start with the very basic principles and gradually build up to a more comprehensive understanding. The goal here is to demystify the concept and show how even the smallest SMB can start benefiting from lean principles without needing to overhaul their entire operation overnight.

Understanding the Core Principles

The foundation of any Lean Ecosystem rests on a few key principles. These aren’t just abstract ideas; they are practical guidelines that, when applied consistently, can transform how an SMB operates. For an SMB, these principles are particularly powerful because they directly address common challenges like limited resources, tight budgets, and the need to be nimble and responsive to market changes.

- Value ● At the heart of Lean is a relentless focus on Value from the customer’s perspective. For an SMB, this means truly understanding what your customers want and are willing to pay for. It’s not just about what you think is valuable, but what your customers perceive as valuable. This could be product features, service quality, speed of delivery, or even the overall customer experience. Identifying and defining value is the first step in eliminating waste and focusing efforts where they truly matter.

- Waste Elimination ● Lean methodologies are famous for their emphasis on eliminating Waste. In an SMB context, waste can manifest in many forms ● excess inventory tying up capital, inefficient processes leading to delays, defects requiring rework, underutilized employee skills, unnecessary transportation of materials, waiting time, and overproduction. By systematically identifying and eliminating these wastes, SMBs can free up resources, reduce costs, and improve efficiency significantly.

- Flow ● Creating a smooth and continuous Flow of processes is crucial. Imagine a river flowing smoothly without any blockages. In a Lean Ecosystem, this means streamlining workflows, removing bottlenecks, and ensuring that processes move seamlessly from one step to the next. For an SMB, this could mean optimizing the order fulfillment Meaning ● Order fulfillment, within the realm of SMB growth, automation, and implementation, signifies the complete process from when a customer places an order to when they receive it, encompassing warehousing, picking, packing, shipping, and delivery. process, improving communication between departments, or simplifying internal approval procedures. A smooth flow reduces lead times, improves responsiveness, and enhances customer satisfaction.

- Pull ● A Pull system means producing goods or services only when there is actual demand. This is in contrast to a push system where production is based on forecasts, often leading to excess inventory. For an SMB, adopting a pull system can significantly reduce inventory costs and minimize the risk of obsolescence. Think of a restaurant that prepares dishes only when orders are placed, rather than cooking large batches in advance. This just-in-time approach ensures freshness, reduces waste, and aligns production with actual customer demand.

- Continuous Improvement (Kaizen) ● Lean is not a one-time project; it’s a journey of Continuous Improvement, often referred to as Kaizen. This principle emphasizes the importance of ongoing efforts to identify and implement incremental improvements across all aspects of the business. For an SMB, this means fostering a culture of problem-solving, encouraging employee feedback, and regularly reviewing processes to identify areas for optimization. Small, consistent improvements over time can lead to significant cumulative gains in efficiency and effectiveness.

These five principles ● Value, Waste Elimination, Flow, Pull, and Continuous Improvement Meaning ● Ongoing, incremental improvements focused on agility and value for SMB success. ● are the cornerstones of a Lean Ecosystem. For an SMB just starting out, understanding and embracing these principles is more important than immediately implementing complex tools or technologies. It’s about shifting the mindset and adopting a lean way of thinking across the organization.

Practical Steps for SMBs to Begin Lean Implementation

Implementing a Lean Ecosystem doesn’t require a massive overhaul or a huge budget. For SMBs, the most effective approach is often to start small, focus on quick wins, and gradually expand the lean principles across the business. Here are some practical first steps that any SMB can take:

- Identify a Problem Area ● Don’t try to fix everything at once. Start by identifying a specific area of your business that is causing pain points or inefficiencies. This could be a process that is slow, costly, or prone to errors. For example, an e-commerce SMB might focus on improving their order fulfillment process, or a service-based SMB might target streamlining their client onboarding process. Choosing a focused area allows for a manageable project and a higher chance of early success.

- Value Stream Mapping (VSM) – Light Version ● While full-scale VSM can be complex, SMBs can benefit from a simplified version. Value Stream Mapping is a visual tool that helps you understand all the steps involved in a process, from start to finish. For an SMB, this could be as simple as drawing a flowchart of the chosen process and identifying areas where waste occurs. For instance, in an order fulfillment process, you might map out steps like order placement, inventory check, picking, packing, shipping, and delivery. Within each step, look for delays, redundancies, or unnecessary steps.

- 5S Methodology for Workplace Organization ● 5S is a simple yet powerful methodology for organizing and standardizing the workplace. It stands for Sort, Set in Order, Shine, Standardize, and Sustain. For an SMB, implementing 5S can dramatically improve efficiency and reduce wasted time searching for tools or materials. This is particularly relevant in warehouses, workshops, or even office environments. A well-organized workspace not only improves productivity but also creates a more professional and pleasant work environment.

- Implement Visual Management ● Visual Management involves using visual cues to communicate information quickly and effectively. This could be as simple as using color-coded labels, Kanban boards for task management, or visual performance dashboards. For an SMB, visual management can improve communication, reduce errors, and make it easier to track progress. For example, a manufacturing SMB could use visual boards to track production progress, or a customer service Meaning ● Customer service, within the context of SMB growth, involves providing assistance and support to customers before, during, and after a purchase, a vital function for business survival. SMB could use dashboards to monitor key metrics like response times and customer satisfaction.

- Encourage Employee Involvement ● Lean is not just about processes; it’s about people. Employee Involvement is crucial for successful Lean Implementation. Encourage your employees to identify problems, suggest improvements, and participate in problem-solving. They are often the closest to the processes and can provide valuable insights. For an SMB, this could mean holding regular team meetings to discuss process improvements, implementing a suggestion box, or creating cross-functional teams to tackle specific problems. Empowering employees fosters a culture of ownership and continuous improvement.

These initial steps are designed to be practical and achievable for SMBs with limited resources. The key is to start with a small, manageable project, demonstrate early successes, and build momentum. As your SMB becomes more comfortable with lean principles, you can gradually expand the implementation to other areas of the business and explore more advanced lean tools and techniques.

Lean Ecosystem Implementation for SMBs starts with understanding core principles and taking small, practical steps to demonstrate early successes and build momentum.

Benefits of Lean Ecosystem Implementation for SMBs

The benefits of implementing a Lean Ecosystem are numerous and directly address the critical needs of SMBs. It’s not just about cutting costs; it’s about building a more resilient, agile, and customer-centric business. For SMBs operating in competitive markets, these benefits can be the key to sustainable growth and long-term success.

- Reduced Costs ● One of the most immediate and tangible benefits of Lean is Cost Reduction. By eliminating waste, streamlining processes, and optimizing resource utilization, SMBs can significantly lower their operating costs. This could be through reduced inventory holding costs, lower material costs due to less waste, reduced labor costs through improved efficiency, or lower defect rates leading to less rework and scrap. For SMBs with tight budgets, these cost savings can be crucial for reinvestment and growth.

- Improved Efficiency and Productivity ● Lean Methodologies are designed to improve efficiency and productivity. By streamlining workflows, eliminating bottlenecks, and standardizing processes, SMBs can get more done with the same or even fewer resources. This translates to faster turnaround times, increased output, and improved resource utilization. For SMBs, this increased efficiency can be a significant competitive advantage, allowing them to respond faster to customer demands and market changes.

- Enhanced Customer Satisfaction ● A Lean Ecosystem is inherently customer-centric. By focusing on delivering value from the customer’s perspective and continuously improving processes to meet their needs, SMBs can significantly enhance Customer Satisfaction. This could be through faster delivery times, higher product quality, improved service responsiveness, or a better overall customer experience. Satisfied customers are more likely to become repeat customers and advocates for your business, driving long-term growth.

- Increased Agility and Flexibility ● Lean principles foster Agility and Flexibility, which are particularly important for SMBs operating in dynamic and uncertain markets. By adopting a pull system, streamlining processes, and empowering employees, SMBs can become more responsive to changes in customer demand, market trends, or competitive pressures. This agility allows them to adapt quickly, seize new opportunities, and navigate challenges more effectively.

- Improved Employee Morale and Engagement ● When implemented effectively, Lean can lead to Improved Employee Morale and Engagement. By involving employees in problem-solving and improvement initiatives, SMBs can create a sense of ownership and empowerment. A more organized and efficient workplace, coupled with opportunities for contribution and growth, can lead to higher job satisfaction and reduced employee turnover. Engaged employees are more productive, innovative, and committed to the success of the business.

These benefits are not just theoretical; they are real and achievable for SMBs of all sizes and industries. The key is to approach Lean Ecosystem Implementation strategically, starting with the fundamentals, focusing on practical steps, and continuously striving for improvement. For an SMB, embracing lean principles is not just about improving operations; it’s about building a foundation for sustainable growth, competitiveness, and long-term success.

Intermediate

Building upon the foundational understanding of Lean Ecosystem Implementation, we now delve into the intermediate aspects, tailored for SMBs that are ready to move beyond the basics. At this stage, SMBs often recognize the potential of lean principles but face challenges in scaling their initial successes and integrating lean thinking more deeply into their organizational fabric. The intermediate phase is about moving from isolated improvements to a more systemic approach, creating a truly interconnected and optimized Business Ecosystem. This requires a deeper understanding of lean tools, strategic alignment, and overcoming common implementation hurdles.

For SMBs at this intermediate level, the focus shifts from simply understanding the ‘what’ and ‘why’ of lean to mastering the ‘how’. It’s about developing the internal capabilities to drive continuous improvement, embedding lean principles into the organizational culture, and leveraging technology to amplify the benefits of lean. This section will explore more advanced lean tools and techniques, discuss strategies for scaling lean initiatives across the SMB, and address the common challenges encountered during intermediate-level implementation.

Advanced Lean Tools and Techniques for SMBs

While the 5S methodology and basic Value Stream Mapping Meaning ● Value Stream Mapping (VSM) is a lean management technique crucial for Small and Medium-sized Businesses (SMBs) seeking growth by visually representing the steps required to deliver a product or service. are excellent starting points, the intermediate phase of Lean Ecosystem Implementation calls for a broader toolkit. SMBs at this stage can benefit from incorporating more sophisticated lean tools and techniques to tackle complex problems and drive deeper levels of optimization. These tools are not inherently complex, but they require a more nuanced understanding and a strategic approach to application.

- Value Stream Mapping (VSM) – Advanced ● Moving beyond the basic flowchart, advanced Value Stream Mapping involves creating detailed current and future state maps. This includes capturing data on cycle times, lead times, inventory levels, and waste at each step of the process. For an SMB, this deeper analysis can reveal hidden bottlenecks and inefficiencies that are not apparent in a simple overview. The future state map then becomes a blueprint for improvement, outlining specific actions to eliminate waste and optimize flow. Advanced VSM often incorporates concepts like takt time, pitch, and flow balancing to design more efficient processes.

- Kanban Systems for Inventory Management ● While basic visual management is helpful, implementing a formal Kanban System can significantly improve inventory management and flow, especially for SMBs dealing with physical products. Kanban is a pull system that uses visual signals (Kanban cards) to trigger production or replenishment only when needed. For an SMB, this can reduce inventory holding costs, minimize stockouts, and improve responsiveness to customer demand. Implementing a Kanban system requires careful analysis of lead times, demand variability, and safety stock levels to ensure smooth operation.

- Poka-Yoke (Mistake-Proofing) ● Poka-Yoke, or mistake-proofing, is a powerful technique for preventing errors from occurring in the first place. It involves designing processes and equipment in a way that makes it impossible or very difficult to make mistakes. For an SMB, implementing Poka-Yoke can significantly reduce defects, rework, and customer complaints. This could range from simple checklists and jigs to more sophisticated automated error detection systems. The key is to proactively identify potential error points and design countermeasures to prevent them.

- Standardized Work ● Standardized Work is the foundation for continuous improvement. It involves documenting the best known method for performing a task or process. For an SMB, standardizing work ensures consistency, reduces variability, and provides a baseline for future improvements. This doesn’t mean stifling creativity; rather, it creates a stable platform from which employees can identify and implement improvements. Standardized work documents should be living documents, regularly reviewed and updated as better methods are discovered.

- Quick Changeover (SMED – Single-Minute Exchange of Die) ● For manufacturing SMBs, Quick Changeover, often referred to as SMED, is a critical technique for reducing setup times. Shorter setup times enable smaller batch sizes, which in turn reduces inventory, improves flow, and increases flexibility. SMED involves analyzing setup processes and converting internal setup tasks (those that can only be done when the machine is stopped) to external setup tasks (those that can be done while the machine is running). For an SMB, reducing changeover times can significantly improve machine utilization and responsiveness to customer orders.

These advanced lean tools and techniques provide SMBs with a more robust arsenal for tackling operational challenges and driving continuous improvement. However, it’s crucial to remember that tools are only effective when applied strategically and within a broader lean framework. The next step is to consider how to scale these initiatives across the entire SMB.

Scaling Lean Initiatives Across the SMB

Initial lean implementations often start in a specific department or process. The intermediate phase of Lean Ecosystem Implementation is about scaling these successes and extending lean principles across the entire SMB. This requires a strategic approach, leadership commitment, and a plan for organizational change Meaning ● Strategic SMB evolution through proactive disruption, ethical adaptation, and leveraging advanced change methodologies for sustained growth. management. Scaling lean is not just about replicating tools and techniques; it’s about fostering a lean culture throughout the organization.

- Develop a Lean Strategy and Roadmap ● Scaling lean requires a clear Strategy and Roadmap. This involves defining the SMB’s overall lean vision, setting specific goals, and outlining a phased approach for implementation across different departments or processes. The roadmap should prioritize areas with the greatest potential for impact and align with the SMB’s overall business objectives. A well-defined strategy provides direction and ensures that lean initiatives are not isolated efforts but part of a cohesive organizational transformation.

- Establish a Lean Leadership Structure ● Leadership Commitment is paramount for successful scaling. This means not just top-level support but also establishing a lean leadership structure throughout the organization. This could involve creating a lean steering committee, appointing lean champions in each department, or developing internal lean coaches. These leaders are responsible for driving lean initiatives, providing guidance and support, and ensuring alignment with the overall lean strategy.

- Standardize Lean Practices and Training ● As lean initiatives expand, it’s crucial to Standardize Lean Practices and Training. This ensures consistency in implementation and builds internal lean capabilities. Develop standardized training programs, create lean toolkits and templates, and establish internal knowledge sharing platforms. This helps to democratize lean knowledge and empower employees at all levels to contribute to continuous improvement.

- Integrate Lean into Performance Management Meaning ● Performance Management, in the realm of SMBs, constitutes a strategic, ongoing process centered on aligning individual employee efforts with overarching business goals, thereby boosting productivity and profitability. Systems ● To sustain lean momentum, it’s essential to Integrate Lean Principles into the SMB’s Performance Management Systems. This means incorporating lean metrics into performance dashboards, setting lean-related goals for individuals and teams, and recognizing and rewarding lean behaviors and achievements. This reinforces the importance of lean and ensures that it becomes an integral part of the SMB’s operational DNA.

- Foster a Culture of Continuous Improvement ● Ultimately, scaling lean is about Fostering a Culture of Continuous Improvement. This requires creating an environment where employees are empowered to identify problems, suggest improvements, and experiment with new solutions. Encourage cross-functional collaboration, celebrate small wins, and learn from failures. A strong lean culture is self-sustaining and drives ongoing innovation and optimization.

Scaling lean across an SMB is a journey, not a destination. It requires patience, persistence, and a commitment to continuous learning and adaptation. As SMBs progress through the intermediate phase, they will inevitably encounter challenges. Understanding and addressing these common hurdles is crucial for sustained success.

Scaling Lean Ecosystem Implementation requires a strategic roadmap, strong leadership, standardized practices, and integration into performance management to foster a culture of continuous improvement across the SMB.

Overcoming Intermediate Implementation Challenges

The intermediate phase of Lean Ecosystem Implementation often presents unique challenges that SMBs must navigate effectively. These challenges are typically related to organizational resistance, resource constraints, and the complexity of integrating lean across multiple functions. Addressing these hurdles proactively is essential to maintain momentum and realize the full potential of a lean ecosystem.

- Resistance to Change ● As lean initiatives expand beyond initial pilot projects, Resistance to Change can become a significant obstacle. Employees may be comfortable with existing processes, skeptical of new methodologies, or fear job displacement. Overcoming resistance requires effective communication, education, and employee involvement. Clearly articulate the benefits of lean, address employee concerns, and provide opportunities for training and participation. Change management Meaning ● Change Management in SMBs is strategically guiding organizational evolution for sustained growth and adaptability in a dynamic environment. is a critical component of successful scaling.

- Resource Constraints ● SMBs often operate with Limited Resources, both financial and human. Scaling lean initiatives may require investments in training, tools, or technology, which can strain already tight budgets. Prioritize lean initiatives based on ROI, focus on low-cost or no-cost improvements, and leverage internal expertise wherever possible. Phased implementation and quick wins can help to demonstrate value and justify further investment.

- Lack of Deep Lean Expertise ● While initial lean implementations may be driven by external consultants or a few internal champions, scaling lean requires building Deeper Lean Expertise within the SMB. Invest in training and development programs to build internal lean capabilities. Encourage employees to become certified lean practitioners, and create opportunities for them to apply their skills and mentor others. Building internal expertise ensures long-term sustainability and reduces reliance on external resources.

- Siloed Organizational Structure ● Traditional Siloed Organizational Structures can hinder the flow of information and collaboration necessary for a lean ecosystem. Lean principles emphasize cross-functional collaboration Meaning ● Cross-functional collaboration, in the context of SMB growth, represents a strategic operational framework that facilitates seamless cooperation among various departments. and process optimization across departments. Break down silos by creating cross-functional teams, promoting open communication, and focusing on process-based rather than functional-based performance metrics. A more integrated organizational structure is essential for realizing the full benefits of lean.

- Maintaining Momentum and Sustaining Gains ● Initial enthusiasm for lean can wane over time, and it can be challenging to Maintain Momentum and Sustain Gains. Continuous improvement is not a one-time project; it’s an ongoing journey. Regularly review progress, celebrate successes, and address setbacks. Embed lean principles into the organizational culture, and ensure that continuous improvement becomes a way of life, not just a series of projects.

Overcoming these intermediate implementation challenges requires a proactive and strategic approach. By addressing resistance to change, managing resource constraints, building internal expertise, breaking down silos, and maintaining momentum, SMBs can successfully navigate the intermediate phase and pave the way for a truly transformative Lean Ecosystem Implementation. The next level of understanding takes us into the advanced realm, exploring the theoretical underpinnings and advanced strategic implications of lean.

Advanced

Lean Ecosystem Implementation, from an advanced perspective, transcends the operational efficiency focus often emphasized in SMB contexts. It represents a strategic paradigm shift, aligning organizational processes, culture, and external relationships towards a holistic value creation system. At its core, scholarly defining Lean Ecosystem Implementation involves understanding it as a complex adaptive system, characterized by interconnectedness, interdependence, and emergent properties.

This definition moves beyond simple waste reduction to encompass a dynamic, evolving network designed for sustained competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. and resilience in the face of market volatility and disruption. This expert-level analysis requires delving into the theoretical underpinnings of lean thinking, examining its cross-sectoral applications, and critically evaluating its long-term strategic implications for SMBs, particularly in the context of automation and digital transformation.

From an advanced viewpoint, Lean Ecosystem Implementation is not merely a set of tools or methodologies, but a comprehensive organizational philosophy. It necessitates a deep understanding of systems thinking, organizational behavior, and strategic management. This section will explore the advanced rigor behind lean principles, drawing upon scholarly research and data to redefine Lean Ecosystem Implementation for SMBs. We will analyze its diverse perspectives, consider multi-cultural business aspects, and examine cross-sectorial influences, ultimately focusing on the profound business outcomes and strategic advantages it can offer to SMBs in the 21st-century business landscape.

Advanced Redefinition of Lean Ecosystem Implementation

Drawing upon reputable business research and scholarly articles, we can redefine Lean Ecosystem Implementation from an advanced perspective, moving beyond the simplified definitions often presented in practitioner-oriented contexts. This redefinition emphasizes the systemic and strategic nature of lean, highlighting its potential to create a sustainable competitive advantage for SMBs.

Lean Ecosystem Implementation, scholarly defined, is:

“A strategically orchestrated, organization-wide transformation initiative that establishes a dynamic and adaptive business ecosystem Meaning ● Strategically orchestrated network enabling SMB resilience and growth through dynamic adaptation. centered on customer value, waste minimization, and continuous improvement, leveraging interconnected processes, empowered human capital, and enabling technologies to achieve operational excellence, enhanced organizational agility, and sustained competitive advantage within a defined market space. This implementation extends beyond internal operations to encompass external stakeholders, fostering collaborative relationships with suppliers, customers, and partners to create a resilient and value-driven network.”

This advanced definition unpacks several key aspects that are crucial for a deep understanding of Lean Ecosystem Implementation:

- Strategic Orchestration ● This emphasizes that lean implementation Meaning ● Lean Implementation: Streamlining SMB operations to eliminate waste, enhance value, and drive sustainable growth through efficiency and customer focus. is not a piecemeal approach but a Strategically Orchestrated initiative. It requires careful planning, alignment with overall business strategy, and a top-down commitment to organizational transformation. Scholarly, this aligns with strategic management Meaning ● Strategic Management, within the realm of Small and Medium-sized Businesses (SMBs), signifies a leadership-driven, disciplined approach to defining and achieving long-term competitive advantage through deliberate choices about where to compete and how to win. theories that emphasize the importance of holistic and integrated approaches to organizational change.

- Dynamic and Adaptive Business Meaning ● Adaptive Business, for Small and Medium-sized Businesses (SMBs), describes the capability to rapidly and effectively adjust strategies, operations, and resources in response to market changes, technological advancements, and evolving customer demands. Ecosystem ● The term Dynamic and Adaptive Business Ecosystem highlights the systemic nature of lean. It’s not just about optimizing individual processes but creating an interconnected network of processes, people, and technologies that can adapt to changing market conditions and customer needs. This resonates with complexity theory and systems thinking, which view organizations as complex adaptive systems.

- Customer Value Centered ● The focus on Customer Value remains central, but scholarly, it’s understood in a more nuanced way. It’s not just about meeting current customer needs but also anticipating future needs and proactively creating value propositions that differentiate the SMB in the marketplace. This aligns with value-based marketing and customer relationship management Meaning ● CRM for SMBs is about building strong customer relationships through data-driven personalization and a balance of automation with human touch. theories.

- Waste Minimization and Continuous Improvement ● Waste Minimization and Continuous Improvement are core lean principles, but scholarly, they are viewed as ongoing, iterative processes that require a deep understanding of process variability and statistical process control. This connects to operations management and quality management theories, emphasizing data-driven decision-making and process optimization.

- Interconnected Processes, Empowered Human Capital, and Enabling Technologies ● This triad highlights the key enablers of a lean ecosystem. Interconnected Processes emphasize the importance of cross-functional collaboration and process integration. Empowered Human Capital underscores the role of employee engagement, knowledge sharing, and skill development. Enabling Technologies recognize the transformative potential of automation, digitalization, and data analytics in amplifying lean benefits. This integrates concepts from organizational behavior, human resource management, and information systems.

- Operational Excellence, Enhanced Organizational Agility, and Sustained Competitive Advantage ● These are the key outcomes of successful Lean Ecosystem Implementation. Operational Excellence refers to achieving superior levels of efficiency, quality, and customer service. Enhanced Organizational Agility signifies the ability to adapt quickly to changing market conditions. Sustained Competitive Advantage is the ultimate goal, ensuring long-term profitability and market leadership. These outcomes are central to strategic management and competitive advantage theories.

- External Stakeholder Collaboration ● Extending beyond internal operations, the definition emphasizes External Stakeholder Collaboration. This recognizes that a truly lean ecosystem encompasses the entire value chain, including suppliers, customers, and partners. Collaborative relationships are crucial for creating a resilient and value-driven network. This aligns with supply chain management and network theory.

This advanced redefinition provides a more comprehensive and nuanced understanding of Lean Ecosystem Implementation, highlighting its strategic depth and transformative potential for SMBs. It moves beyond the tactical application of lean tools to emphasize the creation of a dynamic and adaptive business ecosystem Meaning ● A Business Ecosystem, within the context of SMB growth, automation, and implementation, represents a dynamic network of interconnected organizations, including suppliers, customers, partners, and even competitors, collaboratively creating and delivering value. that drives sustained competitive advantage.

Scholarly, Lean Ecosystem Implementation is a strategically orchestrated, organization-wide transformation creating a dynamic, adaptive, and customer-centric business Meaning ● Prioritizing customer needs to drive SMB growth and build lasting relationships. ecosystem for sustained competitive advantage.

Cross-Sectorial Business Influences and Multi-Cultural Aspects

The advanced understanding of Lean Ecosystem Implementation is further enriched by considering cross-sectorial business influences and multi-cultural aspects. Lean principles, originating from manufacturing, have been successfully applied across diverse sectors, including healthcare, services, and technology. Furthermore, the globalized business environment necessitates an understanding of how cultural differences can impact lean implementation and adaptation.

Cross-Sectorial Influences

Analyzing the application of lean principles across different sectors reveals valuable insights and adaptations that can benefit SMBs:

- Healthcare ● In healthcare, lean principles have been applied to improve patient flow, reduce waiting times, enhance patient safety, and optimize resource utilization. The focus on Patient-Centric Value and Waste Reduction in Processes like patient admission, diagnosis, and treatment provides valuable lessons for service-oriented SMBs. For example, the concept of “value stream mapping” in healthcare can be adapted to map customer journeys in service industries, identifying pain points and areas for improvement.

- Services ● The service sector has embraced lean principles to streamline service delivery processes, improve service quality, and enhance customer experience. Concepts like Service Blueprinting, which is analogous to value stream mapping, help service SMBs visualize and optimize service processes. Focus on Reducing Waiting Time, Eliminating Service Defects, and Standardizing Service Delivery are key takeaways for SMBs in the service industry.

- Technology ● The technology sector, particularly software development, has adopted lean principles through methodologies like Lean Software Development and DevOps. These approaches emphasize iterative development, rapid feedback loops, and continuous delivery of value. The focus on Agile Methodologies, Automation, and Continuous Integration/continuous Delivery (CI/CD) provides valuable insights for SMBs in technology-driven industries. The concept of “minimum viable product (MVP)” and iterative product development are particularly relevant for SMBs launching new products or services.

- Retail ● The retail sector has leveraged lean principles to optimize supply chains, improve inventory management, enhance store operations, and improve customer service. Concepts like Just-In-Time Inventory, Efficient Store Layouts, and Streamlined Checkout Processes are key applications of lean in retail. For SMB retailers, focusing on Reducing Inventory Holding Costs, Improving Store Efficiency, and Enhancing the Customer Shopping Experience are crucial takeaways.

These cross-sectorial applications demonstrate the versatility and adaptability of lean principles. SMBs can learn from these diverse examples and tailor lean methodologies to their specific industry context and business needs. The core principles of value, waste, flow, pull, and continuous improvement remain universally applicable, but their implementation needs to be adapted to the unique characteristics of each sector.

Multi-Cultural Aspects

In today’s globalized business environment, SMBs increasingly operate in multi-cultural contexts, either through international expansion, diverse customer bases, or multicultural workforces. Understanding Multi-Cultural Aspects is crucial for effective Lean Ecosystem Implementation.

- Communication Styles ● Communication Styles vary significantly across cultures. Direct communication styles prevalent in some cultures may be perceived as aggressive in others, while indirect communication styles may lead to misunderstandings in more direct cultures. Lean implementation often involves open communication, feedback, and collaborative problem-solving. SMBs need to be mindful of cultural communication norms and adapt their communication strategies accordingly.

- Decision-Making Processes ● Decision-Making Processes also differ across cultures. Some cultures favor hierarchical decision-making, while others are more consensus-driven. Lean implementation often involves decentralized decision-making and employee empowerment. SMBs need to adapt their decision-making approaches to align with the cultural norms of their workforce and stakeholders.

- Attitudes Towards Change ● Attitudes Towards Change can vary significantly across cultures. Some cultures are more risk-averse and resistant to change, while others are more open to innovation and experimentation. Lean implementation inherently involves organizational change. SMBs need to be sensitive to cultural attitudes towards change and tailor their change management strategies accordingly. Building trust, involving employees in the change process, and demonstrating early successes are crucial for overcoming cultural resistance to change.

- Work Ethic and Values ● Work Ethic and Values also influence lean implementation. Concepts like teamwork, discipline, and continuous improvement may be valued differently across cultures. SMBs need to understand the cultural values of their workforce and align lean principles with these values. For example, in cultures that highly value teamwork, emphasizing collaborative problem-solving and team-based improvements can be particularly effective.

Addressing multi-cultural aspects requires cultural sensitivity, cross-cultural communication skills, and a willingness to adapt lean implementation strategies to different cultural contexts. SMBs operating in global markets or with diverse workforces need to invest in cultural awareness training and develop culturally intelligent leadership to ensure successful Lean Ecosystem Implementation.

In-Depth Business Analysis ● Automation and SMB Lean Ecosystems

Focusing on the influence of automation, we delve into an in-depth business analysis of Lean Ecosystem Implementation for SMBs in the age of digital transformation. Automation, encompassing technologies like robotic process automation Meaning ● Process Automation, within the small and medium-sized business (SMB) context, signifies the strategic use of technology to streamline and optimize repetitive, rule-based operational workflows. (RPA), artificial intelligence (AI), and machine learning (ML), presents both opportunities and challenges for SMBs seeking to build lean ecosystems. This analysis will explore how SMBs can strategically leverage automation to amplify the benefits of lean, address resource constraints, and achieve new levels of operational excellence.

The Synergistic Relationship Between Lean and Automation

Lean principles and automation technologies are not mutually exclusive but rather highly synergistic. Lean Methodologies identify and eliminate waste, streamline processes, and standardize workflows, creating a solid foundation for effective automation. Automation Technologies, in turn, can amplify the benefits of lean by automating repetitive tasks, improving process efficiency, enhancing data accuracy, and enabling real-time process monitoring and optimization.

The synergy between lean and automation can be understood through the following aspects:

- Waste Elimination Amplification ● Automation can significantly amplify Waste Elimination efforts. RPA can automate manual, repetitive tasks, eliminating human errors and reducing processing time. AI-powered systems can analyze large datasets to identify hidden wastes and inefficiencies that humans may miss. For example, AI algorithms can optimize inventory levels, predict equipment failures, and identify process bottlenecks with greater accuracy and speed than traditional methods.

- Process Streamlining and Standardization ● Lean principles emphasize Process Streamlining and Standardization. Automation technologies are most effective when applied to well-defined and standardized processes. By first streamlining and standardizing processes using lean methodologies, SMBs can ensure that automation efforts are focused on value-added activities and avoid automating waste. Standardized digital workflows, enabled by automation platforms, further enhance process consistency and reduce variability.

- Enhanced Data-Driven Decision Making ● Lean emphasizes Data-Driven Decision Making. Automation technologies generate vast amounts of data that can be used to monitor process performance, identify improvement opportunities, and track the impact of lean initiatives. AI and ML algorithms can analyze this data to provide real-time insights, predict future trends, and enable proactive decision-making. For example, real-time dashboards can monitor key performance indicators Meaning ● Key Performance Indicators (KPIs) represent measurable values that demonstrate how effectively a small or medium-sized business (SMB) is achieving key business objectives. (KPIs) and alert managers to deviations from targets, enabling timely corrective actions.

- Improved Scalability and Agility ● Automation enhances Scalability and Agility. Automated processes can be easily scaled up or down to meet changing demand, providing SMBs with greater flexibility and responsiveness. Cloud-based automation platforms offer on-demand scalability and reduce the need for large upfront investments in infrastructure. This agility is particularly crucial for SMBs operating in dynamic and competitive markets.

- Empowered Workforce and Focus on Value-Added Activities ● By automating repetitive and mundane tasks, automation frees up human employees to focus on more Value-Added Activities, such as innovation, customer relationship management, and strategic decision-making. This empowers the workforce, enhances job satisfaction, and leverages human creativity and problem-solving skills. Lean principles emphasize employee empowerment and engagement, and automation can be a powerful enabler of this.

The strategic integration of lean and automation creates a powerful virtuous cycle. Lean methodologies prepare processes for automation, and automation amplifies the benefits of lean, leading to a more efficient, agile, and competitive SMB. However, successful implementation requires careful planning, strategic alignment, and addressing potential challenges.

Strategic Implementation of Automation in SMB Lean Ecosystems

For SMBs, strategic Automation Implementation within a lean ecosystem requires a phased approach, focusing on high-impact areas and leveraging cost-effective automation solutions. A pragmatic and incremental approach is often more suitable for SMBs with limited resources and expertise.

- Identify High-Impact Automation Opportunities ● Start by identifying High-Impact Automation Opportunities that align with lean principles and address key business challenges. Focus on processes that are repetitive, manual, error-prone, and high-volume. Value stream mapping and process analysis can help identify these opportunities. Prioritize automation projects based on ROI, ease of implementation, and strategic alignment. For example, automating invoice processing, order entry, or customer service inquiries can yield significant benefits for many SMBs.

- Choose Cost-Effective Automation Solutions ● SMBs should prioritize Cost-Effective Automation Solutions that are scalable and easy to implement. Cloud-based RPA platforms, low-code/no-code automation tools, and AI-powered software-as-a-service (SaaS) solutions offer affordable and accessible automation options for SMBs. Start with pilot projects to test and validate automation solutions before large-scale deployment. Focus on solutions that can be integrated with existing systems and require minimal IT infrastructure investment.

- Focus on Process Automation, Not Just Task Automation ● Adopt a Process Automation approach rather than just automating individual tasks in isolation. Analyze end-to-end processes and identify opportunities to automate entire workflows. This holistic approach ensures that automation efforts are aligned with lean principles of flow and value stream optimization. For example, automating the entire order fulfillment process, from order placement to delivery, rather than just automating individual steps, can yield greater benefits.

- Empower Employees with Automation Skills ● Invest in Employee Training and Development to build internal automation skills. Empower employees to identify automation opportunities, develop and maintain automation workflows, and leverage automation tools effectively. Citizen development platforms and low-code/no-code tools make automation accessible to non-technical users, enabling wider employee participation in automation initiatives. This fosters a culture of innovation and continuous improvement.

- Measure and Monitor Automation Impact ● Establish Key Performance Indicators (KPIs) to measure and monitor the impact of automation initiatives. Track metrics such as process efficiency, cost savings, error reduction, customer satisfaction, and employee productivity. Regularly review automation performance data and identify areas for optimization and further improvement. Data-driven monitoring ensures that automation investments are delivering the expected benefits and provides insights for future automation strategies.

Strategic automation, when implemented within a lean ecosystem, can be a game-changer for SMBs. It enables them to achieve operational excellence, enhance agility, and compete more effectively in the digital age. However, it’s crucial to address potential challenges and ethical considerations associated with automation.

Strategic automation within a Lean Ecosystem amplifies waste elimination, streamlines processes, enhances data-driven decisions, and empowers SMBs to achieve operational excellence Meaning ● Operational Excellence, within the sphere of SMB growth, automation, and implementation, embodies a philosophy and a set of practices. and agility.

Challenges and Ethical Considerations of Automation in SMB Lean Ecosystems

While automation offers significant benefits, SMBs must also be aware of the potential Challenges and Ethical Considerations associated with its implementation in lean ecosystems.

- Job Displacement Concerns ● One of the primary concerns is Job Displacement due to automation. While automation can create new job roles in areas like automation development and maintenance, it may also displace workers in roles that are heavily reliant on manual and repetitive tasks. SMBs need to address these concerns proactively by providing retraining and upskilling opportunities for employees whose roles may be affected by automation. Focus on transitioning employees to higher-value roles and ensuring a just and equitable transition.

- Implementation Costs and ROI Uncertainty ● While cost-effective automation solutions are becoming more accessible, Implementation Costs can still be a barrier for some SMBs. Furthermore, the Return on Investment (ROI) of automation projects may not always be immediately apparent or guaranteed. SMBs need to conduct thorough cost-benefit analyses, prioritize high-ROI projects, and adopt a phased implementation approach to mitigate financial risks. Starting with small-scale pilot projects and demonstrating early successes can help build confidence and justify further investment.

- Data Security and Privacy Risks ● Automation systems often rely on data, and increased data collection and processing can raise Data Security and Privacy Risks. SMBs need to implement robust cybersecurity measures to protect sensitive data and comply with data privacy regulations. Data encryption, access controls, and regular security audits are essential. Ethical considerations related to data usage, transparency, and consent must also be addressed.

- Over-Automation and Loss of Human Touch ● There is a risk of Over-Automation, where processes become too rigid and inflexible, and the human touch is lost. In customer-facing processes, maintaining a balance between automation and human interaction is crucial. Automation should enhance, not replace, human capabilities. Focus on automating tasks that are best suited for machines, while preserving human roles in areas that require empathy, creativity, and complex problem-solving.

- Ethical Algorithmic Bias ● AI and ML-powered automation systems can be susceptible to Algorithmic Bias, reflecting biases present in the data they are trained on. This can lead to unfair or discriminatory outcomes. SMBs need to be aware of potential biases in AI algorithms and take steps to mitigate them. Data quality, algorithm transparency, and regular audits are crucial for ensuring ethical and unbiased AI-driven automation.

Addressing these challenges and ethical considerations requires a responsible and human-centered approach to automation. SMBs should prioritize employee well-being, data security, ethical AI practices, and maintain a balance between automation and human interaction. By proactively addressing these issues, SMBs can harness the full potential of automation within their lean ecosystems while mitigating potential risks and ensuring a positive impact on their workforce and society.

In conclusion, Lean Ecosystem Implementation, viewed scholarly, is a strategic imperative for SMBs seeking sustained competitive advantage in the 21st century. By embracing a holistic, systemic, and customer-centric approach, leveraging automation strategically, and addressing cross-sectorial and multi-cultural influences, SMBs can build resilient, agile, and high-performing organizations that thrive in the face of complexity and change. The journey towards a lean ecosystem is continuous, requiring ongoing learning, adaptation, and a commitment to excellence.