Fundamentals

In the simplest terms, Industry 4.0 Strategy for Small to Medium Size Businesses (SMBs) represents a fundamental shift in how businesses operate, leveraging advanced technologies to enhance efficiency, productivity, and competitiveness. Imagine your SMB, whether it’s a local bakery, a manufacturing workshop, or a tech startup, becoming smarter, more connected, and more responsive to customer needs. This is the essence of Industry 4.0 for SMBs Meaning ● Industry 4.0 for SMBs: Strategic digital tech integration for SMB growth and resilience. ● it’s about embracing digital transformation Meaning ● Digital Transformation for SMBs: Strategic tech integration to boost efficiency, customer experience, and growth. to optimize every aspect of your business, from production to customer service.

For many SMB owners, the term ‘Industry 4.0’ might sound intimidating, conjuring images of large corporations and complex automation systems. However, the core principles are highly relevant and increasingly accessible to businesses of all sizes. At its heart, Industry 4.0 is about integrating digital technologies like the Internet of Things (IoT), Cloud Computing, Artificial Intelligence (AI), and Automation into traditional business processes. This integration isn’t about replacing human workers with robots overnight, but rather about empowering your existing workforce with better tools and data to make smarter decisions and achieve more with less effort.

Industry 4.0 Strategy for SMBs is about strategically adopting digital technologies to enhance business operations and competitiveness in a practical and scalable way.

Think of it as upgrading your business’s operating system. Just as your computer benefits from software updates that improve performance and add new features, your SMB can benefit from adopting Industry 4.0 technologies. These technologies can help you gain better visibility into your operations, automate repetitive tasks, improve communication with customers and suppliers, and ultimately, drive growth and profitability. For an SMB, this might mean implementing a Customer Relationship Management (CRM) system to better manage customer interactions, using Cloud-Based Accounting Software for real-time financial insights, or employing Sensors in a Manufacturing Setting to monitor equipment performance and predict maintenance needs.

Understanding the Core Components for SMBs

To grasp the fundamentals of Industry 4.0 for SMBs, it’s helpful to break down the key technological components and understand how they can be applied in a practical context.

The Internet of Things (IoT) for SMBs

The Internet of Things (IoT) refers to the network of physical objects ● ‘things’ ● embedded with sensors, software, and other technologies that allow them to collect and exchange data over the internet. For an SMB, this could mean:

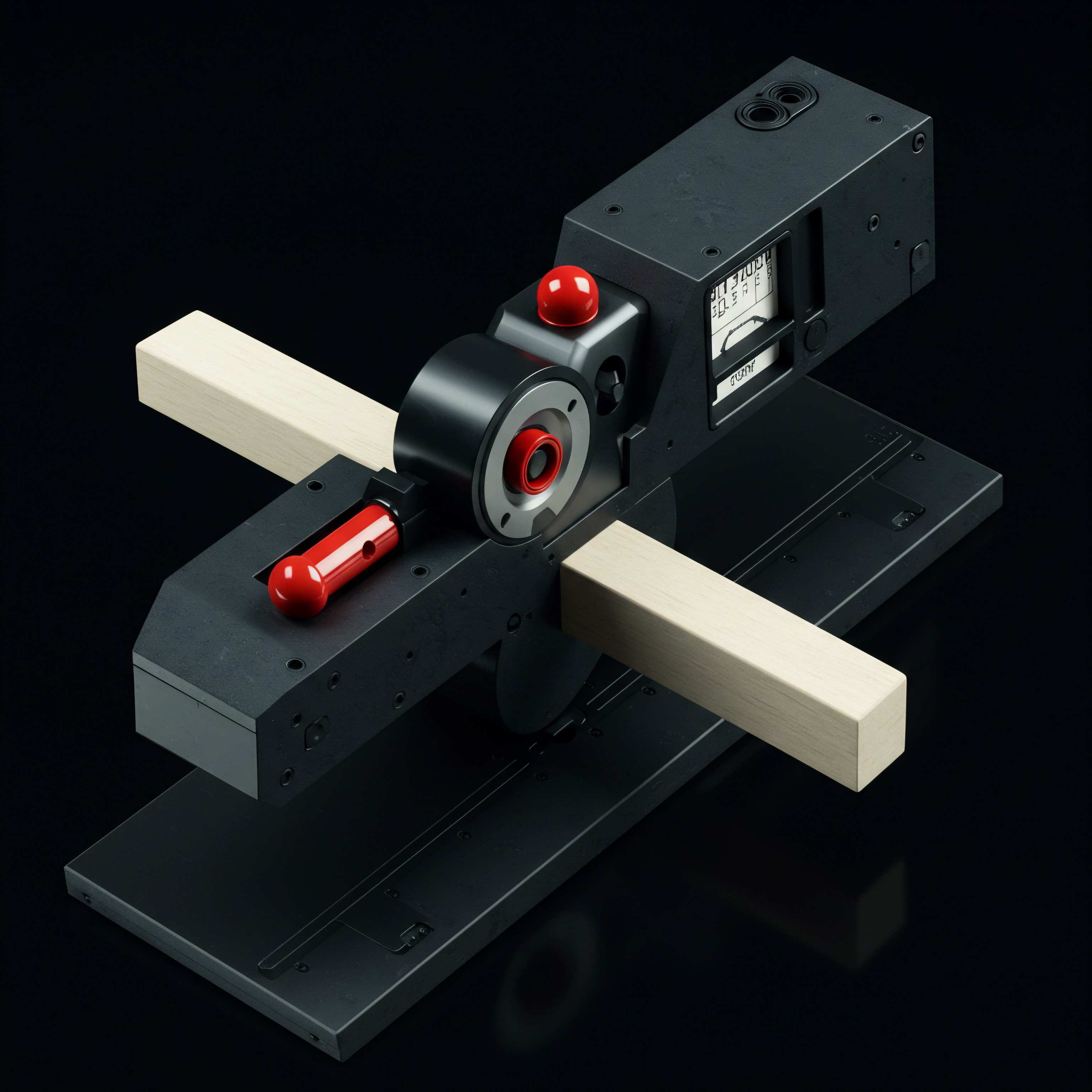

- Smart Sensors in Manufacturing ● Imagine a small manufacturing workshop using sensors on machinery to monitor temperature, vibration, and performance in real-time. This data can be used to predict potential breakdowns, schedule preventative maintenance, and optimize production processes, reducing downtime and improving efficiency.

- Connected Inventory Management ● A retail SMB could use RFID Tags or Barcode Scanners connected to a cloud-based inventory system. This allows for accurate tracking of stock levels, automated reordering when inventory is low, and better insights into product demand, minimizing stockouts and overstocking.

- Smart Logistics and Tracking ● For SMBs involved in delivery or field services, GPS-Enabled Devices and Telematics can provide real-time tracking of vehicles and equipment. This improves route optimization, enhances delivery efficiency, and provides customers with accurate delivery updates, improving customer satisfaction.

The beauty of IoT for SMBs is its scalability. You don’t need to connect every single device at once. You can start with a pilot project in a specific area of your business and gradually expand as you see the benefits.

Cloud Computing for SMBs

Cloud Computing provides access to computing resources ● servers, storage, software, and databases ● over the internet (‘the cloud’) on demand. This eliminates the need for SMBs to invest in and maintain expensive on-premises IT infrastructure. For SMBs, cloud computing Meaning ● Cloud Computing empowers SMBs with scalable, cost-effective, and innovative IT solutions, driving growth and competitive advantage. offers:

- Scalable and Affordable IT Infrastructure ● Instead of buying and maintaining servers, SMBs can subscribe to cloud services and pay only for what they use. This is particularly beneficial for growing SMBs as they can easily scale their IT resources up or down as needed, without significant upfront investment.

- Accessibility and Collaboration ● Cloud-based applications and data are accessible from anywhere with an internet connection, enabling remote work and collaboration among employees. This is crucial for SMBs with distributed teams or those embracing flexible work arrangements.

- Data Backup and Security ● Reputable cloud providers invest heavily in data security Meaning ● Data Security, in the context of SMB growth, automation, and implementation, represents the policies, practices, and technologies deployed to safeguard digital assets from unauthorized access, use, disclosure, disruption, modification, or destruction. and backup infrastructure, often providing better protection than many SMBs could afford on their own. This ensures business continuity and data protection in case of disasters or cyberattacks.

Examples of cloud applications widely used by SMBs include Cloud-Based Accounting Software like Xero or QuickBooks Online, CRM Systems like Salesforce Essentials or HubSpot CRM, and Collaboration Tools like Google Workspace or Microsoft 365.

Artificial Intelligence (AI) and Machine Learning (ML) for SMBs

Artificial Intelligence (AI) and Machine Learning (ML) are often perceived as complex and futuristic, but they are becoming increasingly relevant and accessible to SMBs. AI and ML involve developing computer systems that can perform tasks that typically require human intelligence, such as learning, problem-solving, and decision-making. For SMBs, AI and ML can be applied in various ways:

- Personalized Customer Experiences ● AI-powered chatbots Meaning ● Within the context of SMB operations, AI-Powered Chatbots represent a strategically advantageous technology facilitating automation in customer service, sales, and internal communication. can handle customer inquiries 24/7, providing instant support and freeing up human staff for more complex tasks. Machine Learning Algorithms can analyze customer data to personalize marketing messages, product recommendations, and customer service Meaning ● Customer service, within the context of SMB growth, involves providing assistance and support to customers before, during, and after a purchase, a vital function for business survival. interactions, improving customer engagement Meaning ● Customer Engagement is the ongoing, value-driven interaction between an SMB and its customers, fostering loyalty and driving sustainable growth. and loyalty.

- Automated Business Processes ● Robotic Process Automation (RPA), a subset of AI, can automate repetitive, rule-based tasks such as data entry, invoice processing, and report generation. This frees up employees to focus on higher-value activities, reduces errors, and improves efficiency.

- Predictive Analytics for Decision-Making ● ML algorithms can analyze historical data to identify trends and patterns, enabling SMBs to make more informed decisions. For example, predictive analytics Meaning ● Strategic foresight through data for SMB success. can be used to forecast sales demand, optimize inventory levels, identify potential customer churn, and assess credit risk.

While sophisticated AI applications might require specialized expertise, many SMB-friendly AI tools are becoming available as pre-built solutions or integrated features within existing software platforms. Starting with simple AI applications, like chatbots or basic predictive analytics, can provide significant value without requiring a massive investment.

Automation for SMB Efficiency

Automation is a cornerstone of Industry 4.0 and is particularly crucial for SMBs looking to optimize their operations and compete effectively. Automation involves using technology to perform tasks with minimal human intervention. For SMBs, automation can lead to:

- Increased Productivity and Efficiency ● Automating repetitive tasks frees up employees to focus on more strategic and creative work, leading to increased overall productivity. Automation can also streamline processes, reduce bottlenecks, and improve throughput.

- Reduced Costs and Errors ● Automation can significantly reduce labor costs associated with manual tasks. It also minimizes human errors, leading to improved quality, reduced rework, and lower operational expenses.

- Improved Scalability and Consistency ● Automated processes can be easily scaled up or down to meet changing business demands. Automation also ensures consistency in processes and outputs, leading to more predictable and reliable results.

Automation in SMBs can range from simple tasks like automated email marketing campaigns and social media scheduling to more complex processes like automated order fulfillment and robotic manufacturing. The key is to identify areas where automation can provide the most significant impact and implement solutions that are practical and cost-effective for your SMB.

Why Industry 4.0 Matters for SMB Growth

Adopting an Industry 4.0 Strategy is not just about keeping up with technological trends; it’s about strategically positioning your SMB for sustainable growth Meaning ● Sustainable SMB growth is balanced expansion, mitigating risks, valuing stakeholders, and leveraging automation for long-term resilience and positive impact. and long-term success in an increasingly competitive and digital world. For SMBs, the benefits of embracing Industry 4.0 are multifaceted and directly contribute to key business objectives.

Enhanced Customer Experience

In today’s customer-centric market, providing exceptional customer experiences is paramount. Industry 4.0 technologies enable SMBs to understand their customers better, personalize interactions, and deliver superior service. For example:

- Personalized Marketing and Sales ● By leveraging data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. and CRM systems, SMBs can segment their customer base and tailor marketing messages and sales offers to individual preferences and needs. This leads to higher engagement rates, improved conversion rates, and increased customer loyalty.

- Improved Customer Service and Support ● AI-powered chatbots and automated customer service platforms can provide instant responses to customer inquiries, resolve simple issues quickly, and route complex issues to human agents efficiently. This improves customer satisfaction Meaning ● Customer Satisfaction: Ensuring customer delight by consistently meeting and exceeding expectations, fostering loyalty and advocacy. and reduces customer service costs.

- Proactive Customer Engagement ● IoT data and predictive analytics can enable SMBs to anticipate customer needs and proactively offer solutions or support. For example, a service-based SMB could use IoT data to predict equipment failures and schedule preventative maintenance before issues arise, minimizing customer downtime and maximizing satisfaction.

Operational Efficiency and Cost Reduction

SMBs often operate with limited resources and tight margins. Industry 4.0 technologies offer powerful tools to optimize operations, reduce costs, and improve resource utilization. This can be achieved through:

- Process Automation and Streamlining ● Automating repetitive tasks and streamlining workflows reduces manual labor, minimizes errors, and accelerates processes. This leads to significant cost savings and improved operational efficiency.

- Data-Driven Decision Making ● Industry 4.0 technologies provide real-time data and analytics that enable SMBs to make more informed decisions across all areas of the business. This data-driven approach optimizes resource allocation, improves forecasting accuracy, and enhances overall business performance.

- Predictive Maintenance and Asset Optimization ● IoT sensors and predictive analytics can be used to monitor equipment performance, predict maintenance needs, and optimize asset utilization. This reduces downtime, extends equipment lifespan, and lowers maintenance costs.

Increased Agility and Innovation

In today’s rapidly changing business environment, agility and innovation are crucial for SMB survival and growth. Industry 4.0 technologies empower SMBs to be more adaptable, responsive, and innovative. This includes:

- Faster Time to Market ● Digital technologies and automation can accelerate product development cycles, streamline production processes, and expedite time to market for new products and services. This gives SMBs a competitive edge in fast-paced markets.

- Data-Driven Innovation ● Industry 4.0 provides access to vast amounts of data that can be analyzed to identify new opportunities, understand customer needs, and develop innovative products and services. This data-driven innovation fosters a culture of continuous improvement Meaning ● Ongoing, incremental improvements focused on agility and value for SMB success. and growth.

- Enhanced Collaboration and Ecosystems ● Cloud-based platforms and digital communication tools facilitate seamless collaboration within SMBs and with external partners, suppliers, and customers. This fosters innovation through knowledge sharing, co-creation, and access to broader ecosystems.

In conclusion, understanding the fundamentals of Industry 4.0 Strategy is the first step for SMBs to unlock its transformative potential. By embracing these core technologies and strategically applying them to address specific business challenges and opportunities, SMBs can achieve significant improvements in efficiency, customer experience, and overall competitiveness, paving the way for sustainable growth in the digital age.

Intermediate

Building upon the foundational understanding of Industry 4.0 Strategy, we now delve into the intermediate aspects, focusing on strategic implementation, navigating challenges, and leveraging specific technologies for SMB Growth. At this stage, it’s crucial to move beyond simply understanding the technologies to strategically planning their adoption and integration into your SMB’s operations. This involves developing a clear roadmap, identifying key areas for improvement, and understanding the potential hurdles and how to overcome them.

For SMBs, a successful Industry 4.0 Strategy is not about a wholesale, overnight transformation. It’s about a phased approach, starting with identifying specific business pain points or opportunities where digital technologies can provide tangible benefits. This might involve focusing on improving operational efficiency Meaning ● Maximizing SMB output with minimal, ethical input for sustainable growth and future readiness. in a particular department, enhancing customer engagement through digital channels, or developing new data-driven products or services. The key is to prioritize initiatives that align with your SMB’s overall business goals and resource constraints.

An effective Industry 4.0 Strategy for SMBs is a phased, strategic approach focusing on targeted technology adoption to address specific business needs and drive measurable improvements.

Moving to an intermediate level of understanding requires a deeper dive into the strategic considerations for SMBs. This includes assessing your SMB’s digital readiness, defining clear objectives for your Industry 4.0 initiatives, selecting the right technologies and implementation partners, and establishing metrics to measure success. It’s also essential to consider the organizational and cultural changes that may be necessary to support the adoption of new technologies and processes.

Developing an Industry 4.0 Strategy for SMBs ● A Practical Framework

Creating a robust Industry 4.0 Strategy for your SMB requires a structured approach. Here’s a practical framework that SMBs can adapt and implement:

Step 1 ● Assess Your SMB’s Digital Readiness and Needs

Before embarking on any Industry 4.0 initiative, it’s crucial to honestly assess your SMB’s current digital maturity and identify areas where technology can have the most significant impact. This involves:

- Evaluating Existing Infrastructure and Processes ● Analyze your current IT infrastructure, operational processes, and data management practices. Identify bottlenecks, inefficiencies, and areas where manual processes are time-consuming or error-prone. Consider questions like ● “Where are we losing time and resources?”, “What processes are most prone to errors?”, “Where do we lack visibility into our operations?”

- Identifying Business Goals and Challenges ● Clearly define your SMB’s strategic goals and the challenges you face in achieving them. Are you aiming to increase sales, improve customer satisfaction, reduce costs, or expand into new markets? Understand how Industry 4.0 technologies can directly address these goals and challenges.

- Assessing Skills and Resources ● Evaluate your team’s existing digital skills and identify any skills gaps that need to be addressed. Consider your budget and available resources for technology investments Meaning ● Technology investments, within the SMB landscape, represent strategic allocations of capital toward technological assets. and implementation. SMBs often need to prioritize initiatives that can be implemented with existing resources or with minimal external support initially.

This initial assessment provides a clear picture of your starting point and helps you prioritize areas for Industry 4.0 implementation Meaning ● Strategic integration of digital tech in SMBs for enhanced efficiency and growth. that align with your SMB’s most pressing needs and strategic objectives.

Step 2 ● Define Clear Objectives and KPIs

Once you understand your SMB’s digital readiness and needs, the next step is to define specific, measurable, achievable, relevant, and time-bound (SMART) objectives for your Industry 4.0 initiatives. This involves:

- Setting Specific Goals ● Clearly articulate what you want to achieve with Industry 4.0. Instead of vague goals like “become more digital,” set specific objectives such as “reduce production downtime by 15%,” “increase customer satisfaction scores by 10 points,” or “automate 50% of invoice processing.”

- Identifying Key Performance Indicators (KPIs) ● Define measurable KPIs that will track progress towards your objectives. For example, if your objective is to reduce production downtime, your KPI could be “average machine downtime per month.” If your goal is to improve customer satisfaction, KPIs could include “customer satisfaction score (CSAT)” or “Net Promoter Score (NPS).”

- Establishing Timelines and Milestones ● Set realistic timelines for achieving your objectives and break down your Industry 4.0 initiatives into smaller, manageable milestones. This helps track progress, maintain momentum, and ensure accountability.

Clear objectives and KPIs provide a roadmap for your Industry 4.0 journey and allow you to measure the return on investment (ROI) of your technology implementations.

Step 3 ● Select the Right Technologies and Solutions

With clear objectives and KPIs in place, the next critical step is to select the right technologies and solutions that align with your SMB’s needs and budget. This involves:

- Prioritizing Technologies Based on Impact and Feasibility ● Focus on technologies that offer the highest potential impact on your defined objectives and are feasible to implement within your SMB’s resource constraints. Start with technologies that provide quick wins and demonstrate tangible value.

- Considering Cloud-Based and Scalable Solutions ● For SMBs, cloud-based solutions are often more cost-effective and scalable than on-premises systems. Look for solutions that can grow with your business and offer flexible subscription models.

- Evaluating Vendor Options and Integration Capabilities ● Research different technology vendors and solutions, considering factors like cost, features, ease of use, customer support, and integration capabilities with your existing systems. Choose vendors with a proven track record and experience working with SMBs.

It’s often beneficial for SMBs to start with pilot projects or proof-of-concepts to test different technologies and solutions before making large-scale investments. This allows you to validate the technology’s effectiveness in your specific business context and minimize risks.

Step 4 ● Plan for Implementation and Integration

Successful implementation and integration are crucial for realizing the benefits of Industry 4.0 technologies. This involves:

- Developing a Detailed Implementation Plan ● Create a step-by-step plan outlining the implementation process, including timelines, responsibilities, resource allocation, and potential risks. Break down the implementation into smaller, manageable tasks.

- Ensuring Data Integration Meaning ● Data Integration, a vital undertaking for Small and Medium-sized Businesses (SMBs), refers to the process of combining data from disparate sources into a unified view. and Interoperability ● Plan how new technologies will integrate with your existing systems and data sources. Ensure data interoperability to avoid data silos and maximize the value of your data. Consider using APIs (Application Programming Interfaces) and data integration platforms to facilitate seamless data flow.

- Providing Training and Support for Employees ● Invest in training and support to ensure your employees can effectively use the new technologies and adapt to new processes. Address any concerns or resistance to change and emphasize the benefits of Industry 4.0 for both the business and individual employees.

Change management is a critical aspect of Industry 4.0 implementation. Communicate clearly with your employees about the reasons for the changes, involve them in the process, and provide ongoing support to ensure a smooth transition.

Step 5 ● Monitor, Measure, and Iterate

Industry 4.0 is not a one-time project; it’s an ongoing journey of continuous improvement. After implementation, it’s essential to:

- Monitor KPIs and Track Progress ● Regularly monitor the KPIs you defined in Step 2 to track progress towards your objectives. Use data analytics dashboards and reporting tools to visualize performance and identify areas for improvement.

- Measure ROI and Business Impact ● Assess the ROI of your Industry 4.0 initiatives by comparing the benefits achieved (e.g., cost savings, revenue increase, efficiency gains) against the investments made. Quantify the business impact of your technology implementations.

- Iterate and Optimize ● Based on the data and insights gathered, continuously iterate and optimize your Industry 4.0 strategy. Identify areas where you can further improve processes, leverage new technologies, and adapt to changing business needs. Embrace a culture of continuous learning and improvement.

Regularly reviewing and refining your Industry 4.0 strategy ensures that it remains aligned with your SMB’s evolving business goals and that you are maximizing the value of your technology investments.

Navigating Common Challenges in SMB Industry 4.0 Implementation

While the potential benefits of Industry 4.0 Strategy for SMBs are significant, there are also common challenges that SMBs may encounter during implementation. Understanding these challenges and proactively addressing them is crucial for success.

Challenge 1 ● Limited Resources and Budget Constraints

Description ● SMBs often operate with limited financial and human resources, making large-scale technology investments challenging.

Solutions ●

- Prioritize and Phased Approach ● Focus on high-impact, low-cost initiatives first and adopt a phased implementation approach.

- Cloud-Based Solutions ● Leverage cloud computing to reduce upfront infrastructure costs and benefit from scalable, pay-as-you-go models.

- Government Grants and Funding ● Explore government grants, subsidies, and funding programs available to support SMB digital transformation Meaning ● SMB Digital Transformation: Integrating digital tech to reshape operations, enhance customer value, and drive sustainable growth in the digital age. initiatives.

Challenge 2 ● Lack of Digital Skills and Expertise

Description ● SMBs may lack in-house digital skills and expertise to implement and manage Industry 4.0 technologies.

Solutions ●

- Employee Training and Upskilling ● Invest in training programs to upskill existing employees in digital technologies and data analysis.

- Strategic Partnerships ● Partner with technology vendors, consultants, and system integrators who specialize in SMB Industry 4.0 implementations.

- Outsourcing and Managed Services ● Consider outsourcing specific digital tasks or leveraging managed services for IT infrastructure and support.

Challenge 3 ● Data Security and Privacy Concerns

Description ● Increased connectivity and data collection in Industry 4.0 raise concerns about data security and privacy, especially for sensitive SMB data.

Solutions ●

- Robust Cybersecurity Measures ● Implement strong cybersecurity measures, including firewalls, intrusion detection systems, data encryption, and regular security audits.

- Compliance with Data Privacy Meaning ● Data privacy for SMBs is the responsible handling of personal data to build trust and enable sustainable business growth. Regulations ● Ensure compliance with relevant data privacy regulations Meaning ● Data Privacy Regulations for SMBs are strategic imperatives, not just compliance, driving growth, trust, and competitive edge in the digital age. like GDPR or CCPA.

- Secure Cloud Providers ● Choose reputable cloud providers with robust security certifications and data protection policies.

Challenge 4 ● Integration Complexity and Legacy Systems

Description ● Integrating new Industry 4.0 technologies with existing legacy systems and ensuring data interoperability can be complex and challenging.

Solutions ●

- API-Based Integration ● Utilize APIs to facilitate data exchange and integration between different systems.

- Data Integration Platforms ● Consider using data integration platforms to streamline data flow and ensure data consistency across systems.

- Gradual Modernization ● Adopt a gradual approach to modernizing legacy systems, starting with critical systems and processes.

Challenge 5 ● Resistance to Change and Organizational Culture

Description ● Employees may resist adopting new technologies and processes, and organizational culture Meaning ● Organizational culture is the shared personality of an SMB, shaping behavior and impacting success. may not be conducive to digital transformation.

Solutions ●

- Change Management and Communication ● Implement a comprehensive change management Meaning ● Change Management in SMBs is strategically guiding organizational evolution for sustained growth and adaptability in a dynamic environment. plan with clear communication, employee involvement, and leadership support.

- Demonstrate Value and Benefits ● Clearly communicate the benefits of Industry 4.0 for both the business and individual employees.

- Foster a Culture of Innovation ● Encourage a culture of experimentation, learning, and continuous improvement to embrace digital transformation.

By proactively addressing these common challenges and adopting a strategic, phased approach, SMBs can successfully navigate the complexities of Industry 4.0 Strategy implementation and unlock its transformative potential for growth and competitiveness.

Specific Technology Applications for SMB Growth

To further illustrate the practical application of Industry 4.0 Strategy for SMBs, let’s explore specific technology applications across different business functions and their impact on SMB Growth.

Smart Manufacturing for SMBs

For manufacturing SMBs, Industry 4.0 offers opportunities to optimize production processes, improve quality, and reduce costs. Key applications include:

| Technology Industrial IoT (IIoT) |

| SMB Application Real-time monitoring of machinery performance, predictive maintenance, automated quality control. |

| Growth Impact Reduced downtime, improved efficiency, higher product quality, lower maintenance costs. |

| Technology Robotics and Automation |

| SMB Application Automated assembly lines, robotic welding, automated material handling. |

| Growth Impact Increased production speed, reduced labor costs, improved consistency, enhanced safety. |

| Technology 3D Printing (Additive Manufacturing) |

| SMB Application Rapid prototyping, customized product manufacturing, on-demand spare parts production. |

| Growth Impact Faster product development, personalized products, reduced inventory, new revenue streams. |

| Technology Cloud-Based Manufacturing Execution Systems (MES) |

| SMB Application Real-time production tracking, shop floor management, data-driven process optimization. |

| Growth Impact Improved visibility, enhanced control, optimized resource allocation, increased throughput. |

Smart Retail for SMBs

For retail SMBs, Industry 4.0 can enhance customer experience, optimize inventory management, and personalize marketing. Key applications include:

| Technology Point of Sale (POS) Systems with Analytics |

| SMB Application Real-time sales data, customer purchase history, inventory tracking, sales trend analysis. |

| Growth Impact Data-driven inventory management, personalized promotions, improved customer understanding, increased sales. |

| Technology E-commerce Platforms and Online Marketplaces |

| SMB Application Online sales channels, expanded market reach, 24/7 accessibility, direct customer engagement. |

| Growth Impact Increased revenue, wider customer base, new market opportunities, enhanced brand visibility. |

| Technology Customer Relationship Management (CRM) Systems |

| SMB Application Customer data management, personalized communication, targeted marketing campaigns, customer service automation. |

| Growth Impact Improved customer loyalty, increased customer lifetime value, enhanced customer satisfaction, higher conversion rates. |

| Technology Digital Signage and Interactive Kiosks |

| SMB Application Dynamic product displays, interactive customer engagement, self-service options, personalized recommendations. |

| Growth Impact Enhanced customer experience, increased in-store engagement, improved brand image, optimized staffing. |

Smart Services for SMBs

For service-based SMBs, Industry 4.0 can improve service delivery, enhance customer engagement, and optimize operations. Key applications include:

| Technology Field Service Management (FSM) Software |

| SMB Application Scheduling and dispatching field technicians, real-time location tracking, mobile work orders, customer communication. |

| Growth Impact Improved service efficiency, reduced response times, optimized technician utilization, enhanced customer satisfaction. |

| Technology Remote Monitoring and Diagnostics |

| SMB Application Remote equipment monitoring, proactive issue detection, remote troubleshooting, predictive maintenance scheduling. |

| Growth Impact Reduced on-site visits, faster issue resolution, improved uptime, lower service costs. |

| Technology AI-Powered Chatbots and Virtual Assistants |

| SMB Application 24/7 customer support, instant answers to common questions, appointment scheduling, lead generation. |

| Growth Impact Improved customer service availability, reduced customer service costs, enhanced customer engagement, increased lead generation. |

| Technology Data Analytics for Service Optimization |

| SMB Application Service performance analysis, customer feedback analysis, resource utilization optimization, service trend identification. |

| Growth Impact Data-driven service improvements, optimized resource allocation, enhanced service quality, increased customer retention. |

These examples demonstrate the diverse applications of Industry 4.0 Strategy across different SMB sectors. By strategically selecting and implementing relevant technologies, SMBs can drive significant improvements in efficiency, customer experience, and overall SMB Growth.

Advanced

The advanced understanding of Industry 4.0 Strategy transcends simple definitions, demanding a nuanced exploration of its multifaceted nature, particularly within the context of Small to Medium Size Businesses (SMBs). From an advanced perspective, Industry 4.0 Strategy is not merely the adoption of digital technologies, but a profound paradigm shift that necessitates a re-evaluation of traditional business models, organizational structures, and competitive landscapes. It represents a convergence of physical and digital realms, driven by data, connectivity, and intelligent automation, fundamentally altering value creation and delivery mechanisms for SMBs.

At its core, the advanced definition of Industry 4.0 Strategy for SMBs must acknowledge its dynamic and evolving nature. It is not a static blueprint but rather a continuous process of adaptation and innovation in response to technological advancements, market disruptions, and evolving customer expectations. This necessitates a critical examination of the underlying assumptions, theoretical frameworks, and empirical evidence that inform our understanding of Industry 4.0’s impact on SMBs. Furthermore, a robust advanced definition must consider the diverse perspectives Meaning ● Diverse Perspectives, in the context of SMB growth, automation, and implementation, signifies the inclusion of varied viewpoints, backgrounds, and experiences within the team to improve problem-solving and innovation. and cross-sectoral influences that shape the meaning and implementation of Industry 4.0 across different SMB contexts globally.

Scholarly, Industry 4.0 Strategy for SMBs is defined as a dynamic, multi-dimensional framework encompassing the strategic adoption and integration of cyber-physical systems, IoT, cloud computing, AI, and advanced analytics to achieve enhanced operational efficiency, customer-centricity, and sustainable competitive advantage, requiring continuous adaptation and innovation within diverse SMB ecosystems.

To arrive at a comprehensive advanced definition, we must delve into reputable business research, data points, and credible scholarly domains. This involves analyzing diverse perspectives from leading advanceds, industry experts, and policy makers, considering multi-cultural business aspects and cross-sectorial influences. By critically examining these diverse viewpoints, we can construct a robust and scholarly rigorous definition of Industry 4.0 Strategy tailored specifically to the unique challenges and opportunities faced by SMBs.

Deconstructing the Advanced Meaning of Industry 4.0 Strategy for SMBs

An advanced exploration of Industry 4.0 Strategy for SMBs requires deconstructing its core components and examining them through a critical and analytical lens. This involves considering diverse perspectives, cross-sectoral influences, and potential business outcomes.

Diverse Perspectives on Industry 4.0 Strategy

The advanced discourse on Industry 4.0 Strategy is characterized by diverse perspectives, reflecting the complexity and multi-faceted nature of this phenomenon. These perspectives can be broadly categorized as:

Technological Determinism Vs. Socio-Technical Systems

One perspective, often termed Technological Determinism, emphasizes the transformative power of technology as the primary driver of Industry 4.0. This view posits that technological advancements inherently shape business strategies and organizational structures. However, a more nuanced perspective, grounded in Socio-Technical Systems Theory, argues that technology is only one component of Industry 4.0.

This perspective highlights the crucial interplay between technology, human actors, organizational processes, and the broader social and economic context. For SMBs, this means that successful Industry 4.0 implementation requires not only adopting new technologies but also adapting organizational culture, developing employee skills, and fostering a collaborative ecosystem.

Efficiency-Driven Vs. Innovation-Driven Approaches

Another dichotomy in advanced perspectives revolves around the primary motivation for adopting Industry 4.0. Some view it primarily as an Efficiency-Driven strategy, focused on optimizing existing processes, reducing costs, and improving productivity. This perspective emphasizes operational excellence and incremental improvements. Conversely, an Innovation-Driven approach sees Industry 4.0 as a catalyst for radical innovation, new product development, and the creation of entirely new business models.

For SMBs, the optimal approach may depend on their specific industry, competitive landscape, and strategic goals. While efficiency gains are often a primary driver, the long-term success of SMBs in the Industry 4.0 era may increasingly depend on their ability to leverage these technologies for innovation and differentiation.

Global Value Chains and Regional Clusters

Scholarly, Industry 4.0 Strategy is also viewed through the lens of Global Value Chains (GVCs) and Regional Clusters. Industry 4.0 technologies are reshaping GVCs by enabling greater transparency, traceability, and responsiveness. SMBs operating within GVCs are increasingly expected to adopt digital technologies to meet the demands of larger multinational corporations and participate effectively in global markets.

Furthermore, the concept of Regional Clusters, where geographically concentrated SMBs collaborate and share resources, is becoming increasingly relevant in the Industry 4.0 context. Digital platforms and networks can facilitate collaboration and knowledge sharing within clusters, enhancing the collective competitiveness of SMBs in a region.

Multi-Cultural Business Aspects of Industry 4.0 Strategy

The implementation and impact of Industry 4.0 Strategy are not uniform across different cultures and geographical regions. Multi-Cultural Business Aspects play a significant role in shaping the adoption and outcomes of Industry 4.0 for SMBs. These aspects include:

Cultural Attitudes Towards Technology Adoption

Different cultures exhibit varying levels of openness and acceptance towards new technologies. Some cultures may be more risk-averse and hesitant to adopt unproven technologies, while others may be more innovation-oriented and early adopters. For SMBs operating in diverse cultural contexts, understanding these cultural nuances is crucial for tailoring their Industry 4.0 strategy and communication approaches. For example, in cultures with a strong emphasis on human interaction, SMBs may need to prioritize technologies that enhance human-machine collaboration rather than solely focusing on automation.

Regulatory and Policy Environments

Government regulations and policies related to data privacy, cybersecurity, labor laws, and technology standards vary significantly across countries and regions. These regulatory environments can significantly impact the feasibility and implementation of Industry 4.0 strategies for SMBs. For instance, stringent data privacy regulations may necessitate specific data governance frameworks and technology choices for SMBs operating in certain regions. SMBs need to navigate these diverse regulatory landscapes and ensure compliance in their Industry 4.0 initiatives.

Infrastructure and Digital Divide

The availability and quality of digital infrastructure, including internet access, broadband connectivity, and digital literacy, vary significantly across regions and countries. The Digital Divide, referring to the gap between those with and without access to digital technologies, can create significant disparities in the ability of SMBs to adopt and benefit from Industry 4.0. SMBs in regions with limited digital infrastructure may face significant challenges in implementing cloud-based solutions or IoT applications. Addressing the digital divide and investing in digital infrastructure are crucial for ensuring equitable access to Industry 4.0 opportunities for SMBs globally.

Cross-Sectorial Business Influences on Industry 4.0 Strategy

Industry 4.0 Strategy is not confined to the manufacturing sector; it is increasingly influencing businesses across diverse sectors, including services, retail, agriculture, and healthcare. Cross-Sectorial Business Influences are shaping the evolution and application of Industry 4.0 for SMBs. These influences include:

Service-Oriented Manufacturing and Product-As-A-Service

The traditional boundaries between manufacturing and services are blurring as manufacturers increasingly offer services alongside their products. This trend, known as Service-Oriented Manufacturing or Product-As-A-Service (PaaS), is driven by Industry 4.0 technologies. For SMB manufacturers, this means expanding their value proposition beyond physical products to include digital services, such as remote monitoring, predictive maintenance, and data analytics. This shift requires SMBs to develop new service capabilities and business models.

Data-Driven Agriculture and Precision Farming

In the agricultural sector, Industry 4.0 technologies are enabling Data-Driven Agriculture and Precision Farming. IoT sensors, drones, and data analytics are used to monitor soil conditions, weather patterns, crop health, and livestock performance. This data-driven approach optimizes resource utilization, improves yields, reduces waste, and enhances sustainability in agriculture. For SMBs in the agricultural sector, adopting these technologies can significantly improve efficiency and competitiveness.

Digital Health and Personalized Healthcare

The healthcare sector is also undergoing a digital transformation driven by Industry 4.0. Digital Health technologies, including wearable devices, telehealth platforms, and AI-powered diagnostics, are enabling Personalized Healthcare and remote patient monitoring. For SMBs in the healthcare sector, such as clinics and pharmacies, adopting these technologies can improve patient care, enhance operational efficiency, and expand service offerings.

Smart Retail and Omnichannel Customer Experience

In the retail sector, Smart Retail technologies are transforming the customer experience Meaning ● Customer Experience for SMBs: Holistic, subjective customer perception across all interactions, driving loyalty and growth. and optimizing retail operations. IoT sensors, AI-powered recommendation systems, and omnichannel platforms are enabling personalized shopping experiences, efficient inventory management, and seamless online-offline integration. For SMB retailers, adopting these technologies is crucial for competing with larger online retailers and meeting evolving customer expectations.

In-Depth Business Analysis ● Impact of Industry 4.0 on SMB Supply Chain Resilience

To provide an in-depth business analysis of Industry 4.0 Strategy for SMBs, let’s focus on one specific cross-sectorial influence ● the impact of Industry 4.0 on SMB Supply Chain Resilience. Supply chain resilience, the ability of a supply chain to withstand and recover from disruptions, has become increasingly critical for SMBs in a volatile global environment. Industry 4.0 technologies offer powerful tools to enhance supply chain resilience Meaning ● Supply Chain Resilience for SMBs: Building adaptive capabilities to withstand disruptions and ensure business continuity. for SMBs.

Enhanced Visibility and Transparency

Industry 4.0 technologies, particularly IoT and Blockchain, enable enhanced visibility and transparency across the entire supply chain. IoT sensors can track goods in real-time, providing granular data on location, condition, and movement of products. Blockchain technology can create immutable and transparent records of transactions and product provenance, enhancing trust and traceability. For SMBs, this enhanced visibility allows for proactive monitoring of supply chain risks, early detection of disruptions, and faster response times to mitigate potential impacts.

Predictive Analytics for Risk Management

Predictive Analytics, powered by AI and Machine Learning, can analyze vast amounts of supply chain data to identify potential risks and predict disruptions. By analyzing historical data, real-time sensor data, and external data sources (e.g., weather patterns, geopolitical events), predictive analytics can forecast potential supply chain bottlenecks, demand fluctuations, and supplier risks. For SMBs, this proactive risk management capability allows for anticipatory actions, such as diversifying suppliers, adjusting inventory levels, or rerouting shipments, enhancing supply chain resilience.

Agile and Flexible Manufacturing

Industry 4.0 enables more agile and flexible manufacturing processes, which are crucial for supply chain resilience. 3D Printing and Modular Manufacturing Systems allow for rapid customization and on-demand production, reducing reliance on long lead times and inflexible production lines. Digital Twins, virtual representations of physical assets and processes, enable simulation and optimization of manufacturing operations, enhancing responsiveness to changing demand and supply conditions. For SMB manufacturers, agile and flexible manufacturing capabilities enhance their ability to adapt to disruptions and maintain supply chain continuity.

Decentralized and Distributed Supply Chains

Industry 4.0 facilitates the development of more decentralized and distributed supply chains. Cloud-Based Platforms and Digital Marketplaces enable SMBs to connect with a wider network of suppliers and customers, reducing reliance on single sources and geographical concentrations. Local Manufacturing and Distributed Production Networks, enabled by technologies like 3D printing, can shorten supply chains and reduce vulnerability to global disruptions. For SMBs, diversifying their supply base and adopting more distributed supply chain models enhances resilience and reduces dependence on geographically concentrated or single-source supply chains.

Collaborative Supply Chain Networks

Industry 4.0 fosters the development of collaborative supply chain networks, where SMBs can share data, resources, and risks with partners across the supply chain. Blockchain-Based Platforms and Cloud-Based Collaboration Tools enable secure and transparent data sharing among supply chain partners. Collaborative Planning and Forecasting, facilitated by digital platforms, improve demand visibility and coordination across the supply chain. For SMBs, participating in collaborative supply chain networks enhances collective resilience and enables faster recovery from disruptions through shared resources and coordinated responses.

Long-Term Business Consequences and Success Insights for SMBs

The long-term business consequences of Industry 4.0 Strategy for SMBs are profound and far-reaching. Successful implementation of Industry 4.0 can lead to significant competitive advantages, sustainable growth, and enhanced resilience. However, it also requires SMBs to adapt to new business models, organizational structures, and skill requirements.

Enhanced Competitiveness and Market Differentiation

SMBs that effectively adopt Industry 4.0 Strategy can achieve significant improvements in operational efficiency, product quality, customer experience, and innovation capabilities. These improvements translate into enhanced competitiveness and market differentiation. SMBs can compete more effectively with larger corporations by leveraging digital technologies to offer personalized products and services, respond quickly to market changes, and build stronger customer relationships. Industry 4.0 enables SMBs to niche markets, offer specialized solutions, and build brand loyalty through superior customer service and product quality.

Sustainable Growth and Scalability

Industry 4.0 Strategy provides a foundation for sustainable growth and scalability for SMBs. Digital technologies enable SMBs to automate processes, optimize resource utilization, and expand their market reach. Cloud-based platforms and scalable IT infrastructure allow SMBs to grow without significant upfront investments in physical infrastructure. Data-driven decision-making and predictive analytics enable SMBs to anticipate market trends, optimize operations, and make informed strategic choices, fostering sustainable growth and long-term profitability.

Increased Resilience and Adaptability

As discussed earlier, Industry 4.0 Strategy significantly enhances SMB supply chain Meaning ● SMB Supply Chain, in the context of Small and Medium-sized Businesses, represents the integrated network of organizations, people, activities, information, and resources involved in moving a product or service from supplier to customer. resilience. Beyond supply chains, Industry 4.0 also increases overall business resilience and adaptability. Digital technologies enable SMBs to operate remotely, access global markets, and diversify their revenue streams.

Data analytics and real-time monitoring provide early warning systems for potential risks and disruptions, allowing for proactive responses and business continuity planning. SMBs that embrace Industry 4.0 are better positioned to weather economic downturns, adapt to changing market conditions, and thrive in uncertain environments.

New Business Models and Revenue Streams

Industry 4.0 Strategy opens up opportunities for SMBs to develop new business models and revenue streams. Product-As-A-Service (PaaS) models, data monetization, and digital service offerings are examples of new revenue streams enabled by Industry 4.0 technologies. SMBs can leverage their data assets, digital platforms, and service capabilities to create new value propositions and generate recurring revenue streams. Embracing innovation and exploring new business models are crucial for SMBs to fully capitalize on the transformative potential of Industry 4.0.

Skill Gaps and Workforce Transformation

The adoption of Industry 4.0 Strategy also presents challenges related to skill gaps and workforce transformation. SMBs need to invest in upskilling and reskilling their workforce to adapt to the demands of a digital economy. New roles and skills related to data analytics, AI, IoT, and cybersecurity are becoming increasingly important.

SMBs need to attract and retain talent with these digital skills and foster a culture of continuous learning and adaptation. Addressing the skill gaps and managing workforce transformation Meaning ● Workforce Transformation for SMBs is strategically evolving employee skills and roles to leverage automation and drive sustainable business growth. are critical for successful Industry 4.0 implementation and long-term sustainability.

In conclusion, the advanced understanding of Industry 4.0 Strategy for SMBs is complex and multi-dimensional. It requires a critical examination of diverse perspectives, cross-sectorial influences, and multi-cultural business aspects. By strategically embracing Industry 4.0 technologies and addressing the associated challenges, SMBs can unlock significant opportunities for enhanced competitiveness, sustainable growth, and long-term success in the digital age. The key lies in adopting a holistic and adaptive approach, focusing on strategic alignment, organizational transformation, and continuous innovation.