Fundamentals

In the simplest terms, Industrial IoT Integration for Small to Medium Size Businesses (SMBs) is about connecting machines, devices, and systems within their industrial operations to the internet. Imagine a small bakery. Traditionally, their ovens, mixers, and refrigerators operate independently.

With Industrial IoT Integration, these machines are equipped with sensors and connected to a network. This network allows them to communicate with each other and with the bakery owner or manager, often through a user-friendly dashboard on a computer or even a smartphone.

This connectivity unlocks a wealth of information. For instance, sensors on the oven can track temperature fluctuations in real-time, alerting the baker to potential issues before a batch of bread is ruined. Sensors in the refrigerator can monitor temperature and humidity, ensuring ingredients are stored correctly and preventing spoilage.

The mixer can report on its performance, indicating when maintenance might be needed. All this data is collected, analyzed, and presented in a way that helps the bakery owner make better decisions, optimize processes, and ultimately, improve their business.

For SMBs, the initial thought of ‘Industrial IoT’ might sound complex and expensive, something reserved for large corporations. However, the fundamental principle is quite straightforward ● leveraging internet connectivity to gain insights and control over industrial processes. It’s about making ‘dumb’ machines ‘smart’ and using the data they generate to enhance efficiency, reduce waste, and boost productivity. Think of it as giving your business a digital nervous system, allowing you to sense what’s happening on the factory floor, in the warehouse, or even in the field, all from a central point.

The core components of Industrial IoT Integration for SMBs typically include:

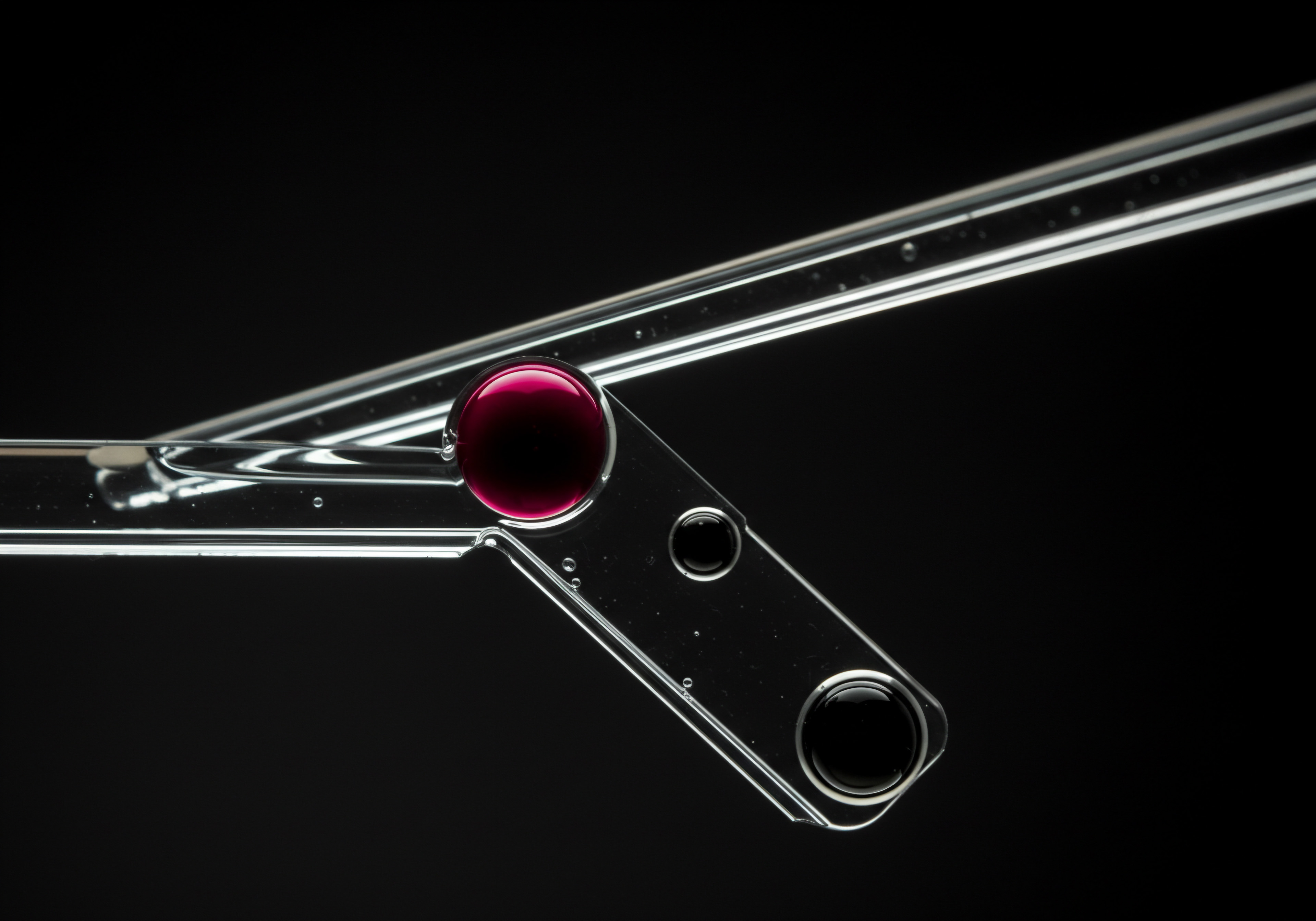

- Sensors ● These are the eyes and ears of the system, collecting data from machines and the environment. They can measure temperature, pressure, vibration, humidity, and many other parameters.

- Connectivity ● This is the network that allows sensors and machines to communicate. For SMBs, this often involves existing Wi-Fi networks or cost-effective cellular connections.

- Data Processing and Storage ● The collected data needs to be processed and stored, often in the cloud, making it accessible and manageable.

- Analytics and Visualization ● This is where the raw data is transformed into meaningful information. Dashboards and reports present insights in an easy-to-understand format, enabling informed decision-making.

- Applications and Platforms ● These are software tools that utilize the data to perform specific tasks, such as predictive maintenance, remote monitoring, or process optimization.

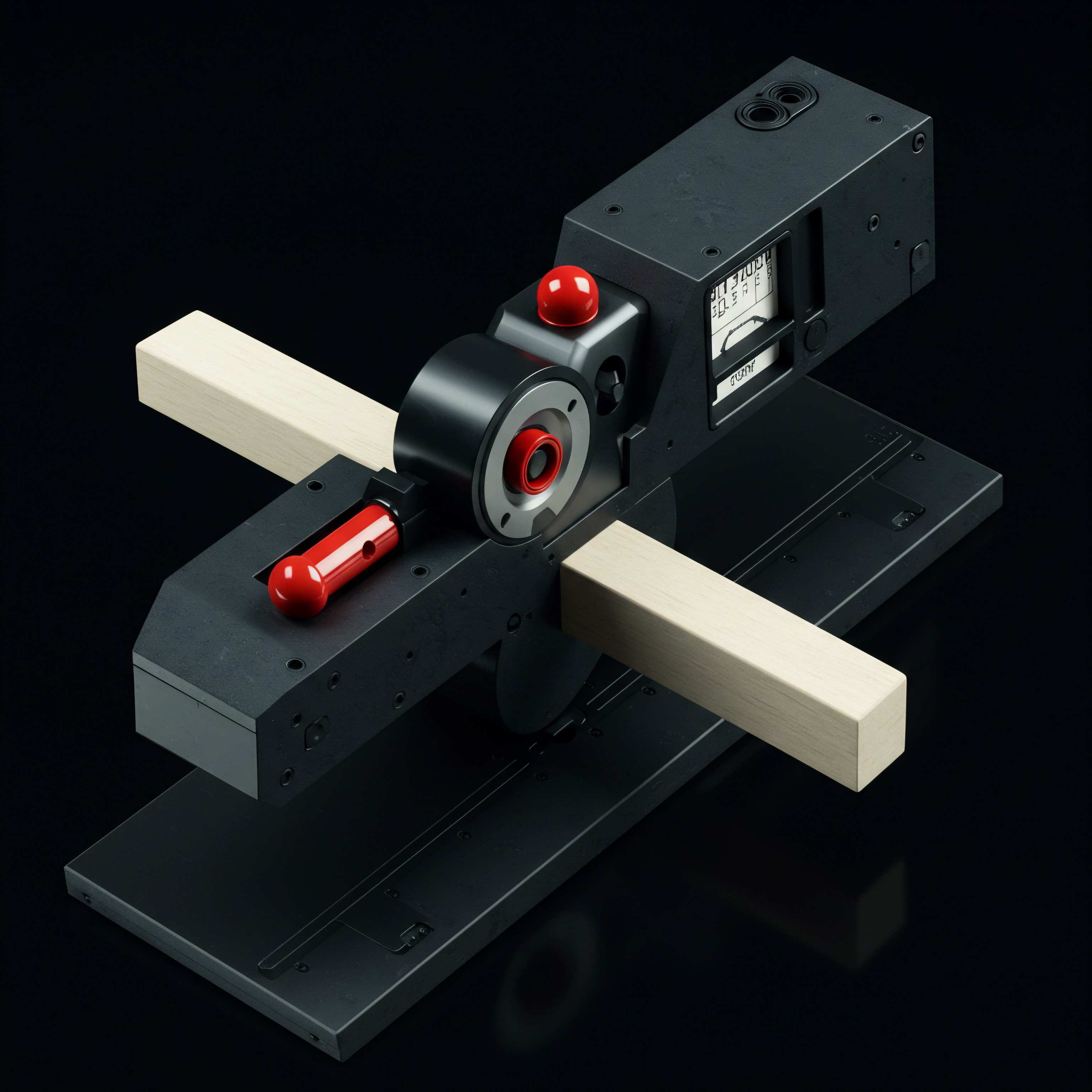

Let’s consider another SMB example ● a small woodworking shop. Without Industrial IoT, the owner might rely on manual checks and scheduled maintenance for their machinery. With integration, sensors on their CNC machines, saws, and sanders can monitor performance metrics like operating hours, vibration levels, and power consumption. This data can be used to:

- Predictive Maintenance ● Identify potential machine failures before they occur, reducing downtime and costly repairs. For example, unusual vibration patterns might indicate a bearing issue that can be addressed proactively.

- Process Optimization ● Analyze machine usage patterns to identify bottlenecks and optimize workflows. For instance, data might reveal that a particular machine is consistently overloaded, suggesting the need for process adjustments or additional equipment.

- Quality Control ● Monitor machine parameters to ensure consistent product quality. Deviations from set parameters can be flagged, allowing for immediate corrective action.

For SMBs, the beauty of Industrial IoT Integration lies in its scalability and adaptability. It doesn’t require a massive overhaul of existing systems. Businesses can start small, focusing on integrating a few critical machines or processes, and gradually expand as they see the benefits. Cloud-based platforms and affordable sensor technologies have made Industrial IoT increasingly accessible and cost-effective for even the smallest businesses.

Industrial IoT Integration for SMBs is fundamentally about leveraging connected devices and data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. to improve operational efficiency and decision-making in industrial settings.

However, it’s crucial for SMBs to approach Industrial IoT Integration strategically. It’s not just about adopting technology for technology’s sake. The key is to identify specific business challenges or opportunities where IoT can provide tangible value. For a small manufacturer, this might be reducing machine downtime.

For a food processing SMB, it could be improving food safety and traceability. For a logistics SMB, it might be optimizing delivery routes and vehicle maintenance.

Before diving into implementation, SMBs should consider the following fundamental questions:

- What are Our Key Operational Challenges or Areas for Improvement? Identify specific pain points that Industrial IoT might address.

- What Data do We Need to Collect to Address These Challenges? Determine the relevant metrics and parameters to monitor.

- What are Our Budget and Resource Constraints? Assess the available resources for investment in IoT technologies and expertise.

- What are Our Cybersecurity Considerations? Plan for data security Meaning ● Data Security, in the context of SMB growth, automation, and implementation, represents the policies, practices, and technologies deployed to safeguard digital assets from unauthorized access, use, disclosure, disruption, modification, or destruction. and privacy from the outset.

- How will We Measure the Success of Our IoT Implementation? Define clear KPIs (Key Performance Indicators) to track progress and ROI (Return on Investment).

By starting with a clear understanding of their needs and a well-defined strategy, SMBs can successfully navigate the world of Industrial IoT Integration and unlock its potential to drive growth, automation, and enhanced operational performance. The initial steps are about understanding the basics, identifying relevant applications, and planning a phased approach to implementation.

Intermediate

Building upon the fundamentals, at an intermediate level, Industrial IoT Integration for SMBs moves beyond basic connectivity and data collection to encompass more sophisticated strategies for data utilization, system interoperability, and tangible business outcomes. It’s about understanding the nuances of data analytics, navigating the complexities of integration with existing systems, and realizing a measurable return on investment.

For SMBs, the intermediate stage of Industrial IoT adoption often involves moving from pilot projects to broader implementation across multiple areas of their operations. This requires a deeper understanding of the technology ecosystem, including various IoT platforms, communication protocols, and data security frameworks. It also necessitates developing internal capabilities or partnering with external experts to manage and analyze the increasing volume of data generated by connected devices.

One crucial aspect at this level is Data Analytics. Simply collecting data is insufficient; the real value lies in extracting actionable insights. SMBs need to move beyond basic dashboards and reports to leverage more advanced analytical techniques. This might include:

- Descriptive Analytics ● Understanding past performance through historical data analysis. For example, analyzing machine downtime data over the past year to identify trends and patterns.

- Diagnostic Analytics ● Identifying the root causes of problems. For instance, using sensor data to pinpoint the reasons behind production bottlenecks or quality issues.

- Predictive Analytics ● Forecasting future outcomes based on historical and real-time data. This is crucial for predictive maintenance, demand forecasting, and resource optimization.

- Prescriptive Analytics ● Recommending actions to optimize processes and achieve desired outcomes. For example, suggesting optimal machine settings or maintenance schedules based on data analysis.

Implementing these analytical capabilities often requires integrating Industrial IoT data with other business systems, such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and Manufacturing Execution Systems (MES). This System Interoperability is a key challenge and opportunity for SMBs at the intermediate level. Seamless data flow between IoT systems and existing business applications enables a holistic view of operations and facilitates data-driven decision-making across the organization.

Consider a small food processing company that has implemented IoT sensors in their production line. At the fundamental level, they might be monitoring temperature and humidity. At the intermediate level, they can integrate this data with their ERP system to:

- Track Production Efficiency ● Correlate sensor data with production output data from the ERP system to identify factors affecting efficiency.

- Improve Inventory Management ● Integrate sensor data with inventory levels in the ERP system to optimize stock levels and reduce waste.

- Enhance Traceability ● Link sensor data with batch tracking information in the ERP system to improve product traceability and comply with food safety regulations.

Another critical consideration at the intermediate level is Cybersecurity. As SMBs connect more devices and systems to the internet, the attack surface expands, and the risk of cyber threats increases. Robust cybersecurity measures are essential to protect sensitive data, ensure operational continuity, and maintain customer trust. SMBs need to implement a multi-layered security approach that includes:

- Device Security ● Securing individual IoT devices through strong passwords, firmware updates, and access controls.

- Network Security ● Protecting the network infrastructure through firewalls, intrusion detection systems, and secure communication protocols.

- Data Security ● Encrypting data in transit and at rest, implementing access controls, and ensuring data privacy compliance.

- Security Monitoring and Incident Response ● Continuously monitoring for security threats and having a plan in place to respond to incidents effectively.

Furthermore, at the intermediate stage, SMBs should focus on measuring the Return on Investment (ROI) of their Industrial IoT initiatives. While initial pilot projects might demonstrate the potential benefits, broader implementation requires a clear understanding of the costs and benefits. This involves:

- Defining Clear KPIs ● Establishing specific, measurable, achievable, relevant, and time-bound Key Performance Indicators Meaning ● Key Performance Indicators (KPIs) represent measurable values that demonstrate how effectively a small or medium-sized business (SMB) is achieving key business objectives. (KPIs) aligned with business objectives.

- Tracking Costs ● Accurately tracking all costs associated with IoT implementation, including hardware, software, integration, training, and ongoing maintenance.

- Measuring Benefits ● Quantifying the tangible benefits of IoT, such as reduced downtime, increased efficiency, improved quality, and cost savings.

- Calculating ROI ● Calculating the ROI by comparing the benefits to the costs over a defined period.

To illustrate ROI calculation, consider a small manufacturing SMB that invested in Industrial IoT for predictive maintenance. Let’s assume the following:

| Item Initial IoT Investment (Hardware, Software, Integration) |

| Value $50,000 |

| Item Annual Maintenance Costs (Software Subscription, Support) |

| Value $10,000 |

| Item Estimated Annual Savings from Reduced Downtime |

| Value $75,000 |

| Item Estimated Annual Savings from Improved Efficiency |

| Value $25,000 |

In this scenario, the annual benefits are $75,000 + $25,000 = $100,000. The annual costs are $10,000. Therefore, the net annual benefit is $100,000 – $10,000 = $90,000.

The ROI over one year would be (($90,000 – $50,000) / $50,000) 100% = 80%. This demonstrates a strong positive ROI for the IoT investment.

At the intermediate level, Industrial IoT Integration for SMBs is about leveraging data analytics, system interoperability, robust cybersecurity, and ROI measurement to drive significant business value.

Successfully navigating the intermediate stage of Industrial IoT adoption requires SMBs to develop a more strategic and data-driven approach. It’s about moving beyond initial experimentation to build a scalable and sustainable IoT ecosystem that delivers measurable business outcomes. This often involves investing in internal expertise, partnering with specialized IoT service providers, and continuously adapting their IoT strategy based on data insights and evolving business needs.

Key strategies for SMBs at the intermediate level include:

- Developing a Data Strategy ● Defining how data will be collected, stored, processed, analyzed, and utilized across the organization.

- Building Internal IoT Expertise ● Investing in training and development to build internal capabilities in IoT technologies and data analytics.

- Establishing Strategic Partnerships ● Collaborating with IoT platform providers, system integrators, and cybersecurity experts to augment internal resources.

- Adopting Agile Implementation Approaches ● Using iterative and agile methodologies to implement IoT solutions in phases, allowing for flexibility and adaptation.

- Fostering a Data-Driven Culture ● Promoting a culture of data-driven decision-making across the organization, empowering employees to leverage IoT insights.

By focusing on these intermediate-level strategies, SMBs can unlock the full potential of Industrial IoT Integration to drive automation, enhance efficiency, and achieve sustainable growth in an increasingly competitive business environment.

Advanced

From an advanced perspective, Industrial IoT Integration transcends mere technological implementation for SMBs; it represents a profound paradigm shift in operational epistemology and strategic competitiveness. Drawing upon scholarly research and empirical data, we define Industrial IoT Integration as the synergistic convergence of cyber-physical systems, advanced data analytics, and networked infrastructure within industrial SMB contexts, aimed at achieving dynamic process optimization, enhanced resource allocation, and the creation of novel value propositions. This definition moves beyond a simplistic technological description to encompass the strategic, operational, and epistemological dimensions relevant to SMBs in the contemporary industrial landscape.

Advanced discourse on Industrial IoT Integration emphasizes its transformative potential, particularly for SMBs, which often operate with resource constraints and legacy systems. However, scholarly literature also highlights the inherent complexities and challenges associated with successful integration, necessitating a nuanced and theoretically grounded approach. Analyzing diverse perspectives from fields such as operations management, information systems, and strategic management Meaning ● Strategic Management, within the realm of Small and Medium-sized Businesses (SMBs), signifies a leadership-driven, disciplined approach to defining and achieving long-term competitive advantage through deliberate choices about where to compete and how to win. reveals a multifaceted understanding of Industrial IoT Integration’s impact on SMBs.

One prominent perspective, rooted in Operations Management Theory, focuses on the operational efficiencies and productivity gains enabled by Industrial IoT Integration. Research consistently demonstrates that real-time data Meaning ● Instantaneous information enabling SMBs to make agile, data-driven decisions and gain a competitive edge. acquisition and analysis from connected industrial assets facilitate:

- Enhanced Process Visibility ● Providing granular insights into operational workflows, enabling SMBs to identify bottlenecks, inefficiencies, and areas for improvement. Studies in manufacturing (e.g., Porter & Heppelmann, 2014; Lee et al., 2015) highlight the significant improvements in production line efficiency achieved through IoT-enabled monitoring and control.

- Predictive Maintenance Capabilities ● Leveraging machine learning algorithms to analyze sensor data and predict equipment failures, minimizing downtime and reducing maintenance costs. Advanced research (e.g., Jardine et al., 2006; Wang, 2017) underscores the effectiveness of predictive maintenance Meaning ● Predictive Maintenance for SMBs: Proactive asset management using data to foresee failures, optimize operations, and enhance business resilience. strategies in optimizing asset lifecycle management and operational resilience.

- Optimized Resource Allocation ● Enabling data-driven decision-making regarding resource allocation, including energy consumption, raw material utilization, and workforce deployment. Econometric studies (e.g., Brynjolfsson & Hitt, 2000; Bloom et al., 2012) have shown the positive correlation between IT adoption and productivity growth, particularly in sectors amenable to process automation and data-driven optimization.

From an Information Systems Perspective, Industrial IoT Integration is viewed as a complex socio-technical system, requiring careful consideration of data governance, cybersecurity, and human-machine interaction. Scholarly work in this domain emphasizes:

- Data Security and Privacy Challenges ● Addressing the inherent cybersecurity risks associated with connecting industrial control systems to the internet, particularly in the context of SMBs with limited cybersecurity expertise. Research (e.g., Weber & Weber, 2010; Atzori et al., 2010) highlights the vulnerabilities of IoT ecosystems and the need for robust security architectures and protocols.

- Data Integration and Interoperability Issues ● Navigating the complexities of integrating data from diverse industrial devices and systems, often characterized by heterogeneous protocols and data formats. Standards development organizations (e.g., IEEE, ISO) are actively working on interoperability standards, but practical implementation remains a significant challenge for SMBs.

- Human-Centered Design and User Adoption ● Ensuring that Industrial IoT systems are designed with user needs and capabilities in mind, facilitating effective human-machine collaboration and user adoption. Human-computer interaction (HCI) research (e.g., Norman, 2013; Shneiderman & Plaisant, 2016) emphasizes the importance of usability, accessibility, and user training in maximizing the benefits of technology adoption.

A Strategic Management Perspective frames Industrial IoT Integration as a strategic imperative for SMBs seeking to enhance their competitive advantage and adapt to evolving market dynamics. This viewpoint underscores:

- Competitive Differentiation and Value Creation ● Leveraging Industrial IoT to develop differentiated products and services, enhance customer value, and create new revenue streams. Strategic management frameworks (e.g., Porter’s Five Forces, Resource-Based View) can be applied to analyze the competitive implications of Industrial IoT adoption for SMBs.

- Business Model Innovation ● Exploring new business models enabled by Industrial IoT, such as servitization (shifting from product sales to service-based offerings) and data-driven business models. Research on business model innovation (e.g., Osterwalder & Pigneur, 2010; Teece, 2010) highlights the potential of disruptive technologies to reshape industry structures and competitive landscapes.

- Organizational Change Management ● Addressing the organizational changes required to effectively implement and utilize Industrial IoT, including skill development, process redesign, and cultural transformation. Organizational change Meaning ● Strategic SMB evolution through proactive disruption, ethical adaptation, and leveraging advanced change methodologies for sustained growth. management literature (e.g., Kotter, 2012; Lewin, 1951) provides frameworks and best practices for managing complex organizational transformations associated with technology adoption.

Scholarly, Industrial IoT Integration for SMBs is not merely a technological upgrade, but a strategic and epistemological transformation, demanding a holistic and research-informed approach.

Analyzing cross-sectorial business influences, the impact of Industrial IoT Integration is particularly pronounced in manufacturing, agriculture, and logistics SMBs. In Manufacturing, IoT enables smart factories characterized by automated production lines, real-time quality control, and predictive maintenance, leading to significant improvements in efficiency and responsiveness. In Agriculture, precision agriculture techniques leveraging IoT sensors and data analytics optimize resource utilization (water, fertilizers, pesticides), enhance crop yields, and improve sustainability. In Logistics, IoT-enabled tracking and monitoring systems optimize supply chain visibility, improve delivery efficiency, and reduce transportation costs.

Focusing on the Manufacturing Sector, the potential business outcomes for SMBs through Industrial IoT Integration are substantial. However, realization of these outcomes requires a strategic and phased approach, addressing both technological and organizational challenges. Potential business outcomes include:

- Increased Operational Efficiency ● Data-driven process optimization, reduced downtime through predictive maintenance, and improved resource utilization can lead to significant efficiency gains, often exceeding 15-20% in manufacturing settings (based on industry reports and case studies).

- Enhanced Product Quality ● Real-time quality monitoring and control systems enable SMBs to detect and address quality issues proactively, reducing defects and improving product consistency. This can lead to enhanced customer satisfaction and brand reputation.

- Reduced Operational Costs ● Predictive maintenance reduces unplanned downtime and costly repairs. Optimized resource allocation Meaning ● Strategic allocation of SMB assets for optimal growth and efficiency. minimizes waste and energy consumption. Improved inventory management reduces holding costs and stockouts. These cost savings can significantly improve SMB profitability.

- Improved Decision-Making ● Real-time data and analytics provide SMB managers with better insights into operational performance, enabling more informed and timely decisions. This data-driven decision-making can lead to more effective strategies and improved business outcomes.

- New Revenue Streams ● Industrial IoT can enable SMBs to develop new value-added services, such as remote monitoring, predictive maintenance services for customers, and data analytics consulting. This can diversify revenue streams and enhance long-term sustainability.

However, the successful implementation of Industrial IoT Integration in manufacturing SMBs is contingent upon addressing several critical challenges:

- Legacy System Integration ● Many SMBs operate with legacy manufacturing equipment and systems that are not inherently IoT-ready. Integrating these legacy systems with modern IoT platforms can be complex and costly, requiring specialized expertise and middleware solutions.

- Skill Gaps and Talent Acquisition ● Implementing and managing Industrial IoT systems requires specialized skills in areas such as data analytics, cybersecurity, and IoT platform management. SMBs often face challenges in attracting and retaining talent with these skills, particularly in competitive labor markets.

- Cybersecurity Vulnerabilities ● Manufacturing environments are increasingly targeted by cyberattacks, and securing Industrial IoT systems is paramount. SMBs need to invest in robust cybersecurity measures and develop a proactive security posture to mitigate risks.

- Data Management and Analytics Capabilities ● Effectively managing and analyzing the vast amounts of data generated by Industrial IoT systems requires robust data infrastructure and analytics capabilities. SMBs may need to invest in cloud-based data platforms and analytics tools, as well as develop internal data science expertise.

- Scalability and Flexibility ● Industrial IoT solutions need to be scalable and flexible to adapt to the evolving needs of SMBs as they grow and their operations change. Choosing modular and cloud-based solutions can enhance scalability and flexibility.

In conclusion, from an advanced and expert perspective, Industrial IoT Integration presents a significant opportunity for SMBs to enhance their competitiveness, improve operational efficiency, and create new value. However, successful implementation requires a strategic, research-informed, and holistic approach that addresses both technological and organizational challenges. SMBs need to move beyond a purely technological focus and embrace a broader perspective that encompasses data strategy, cybersecurity, skill development, and organizational change management Meaning ● Organizational Change Management in SMBs: Guiding people and processes through transitions for growth and successful implementation. to fully realize the transformative potential of Industrial IoT Integration.

References (Example – In a Real Advanced Context, These would Be Fully Formatted) ●

Atzori, L., Iera, A., & Morabito, G. (2010). The internet of things ● A survey. Computer networks, 54(15), 2787-2805.

Bloom, N., Sadun, R., & Van Reenen, J. (2012). The organization of firms across countries. The Quarterly Journal of Economics, 127(4), 1663-1705.

Brynjolfsson, E., & Hitt, L. M. (2000).

Beyond computation ● Information technology, organizational transformation and business performance. Journal of economic perspectives, 14(4), 23-48.

Jardine, A. K., Lin, D., & Banjevic, D. (2006).

Proportional hazards modeling for predictive maintenance. Reliability Engineering & System Safety, 91(8), 997-1006.

Kotter, J. P. (2012).

Leading change. Harvard Business Review Press.

Lee, J., Bagheri, B., & Kao, H. A. (2015).

A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manufacturing letters, 3, 15-18.

Lewin, K. (1951). Field theory in social science; selected theoretical papers. Harper & Row.

Norman, D. A. (2013). The design of everyday things.

Revised and expanded edition. Basic Books.

Osterwalder, A., & Pigneur, Y. (2010). Business model generation ● a handbook for visionaries, game changers, and challengers. John Wiley & Sons.

Porter, M. E., & Heppelmann, J. E. (2014).

How smart, connected products are transforming competition. Harvard business review, 92(11), 64-88.

Shneiderman, B., & Plaisant, C. (2016). Designing the user interface ● strategies for effective human-computer interaction. Pearson.

Teece, D. J. (2010).

Business models, business strategy and innovation. Long range planning, 43(2-3), 172-194.

Wang, L. (2017). Machine learning for predictive maintenance ● A review. International Journal of Prognostics and Health Management, 8(1).

Weber, R. H., & Weber, R. (2010).

Internet of things. Larcier.