Fundamentals

In the realm of modern business, particularly for Small to Medium-Sized Businesses (SMBs), the concept of Circular Manufacturing is gaining significant traction. To understand its fundamental meaning, we must first consider the traditional linear model of manufacturing. This linear approach, often termed ‘take-make-dispose’, involves extracting raw materials, manufacturing products, and then discarding them at the end of their life cycle.

This model, while historically prevalent, is increasingly recognized as unsustainable due to resource depletion, environmental degradation, and escalating waste management costs. For SMBs, operating within this linear framework can lead to vulnerabilities in supply chains, price volatility of raw materials, and growing pressure from consumers and regulators for more sustainable practices.

Circular Manufacturing, at its core, represents a paradigm shift from this linear model to a closed-loop system, aiming to minimize waste and maximize resource utilization.

The Definition of Circular Manufacturing, in its simplest form, is a system where resources are kept in use for as long as possible, extracting the maximum value from them whilst in use, then recovering and regenerating products and materials at the end of each service life. This Explanation emphasizes a shift from a ‘cradle-to-grave’ to a ‘cradle-to-cradle’ approach. For SMBs, this transition is not merely an environmental consideration but also a strategic business imperative. Embracing circularity can unlock new revenue streams, enhance brand reputation, and build resilience against resource scarcity.

Understanding the Core Principles

To grasp the Meaning of Circular Manufacturing for SMBs, it’s crucial to delineate its core principles. These principles provide a framework for understanding how circularity can be implemented and what benefits it can offer.

- Design for Durability and Longevity ● This principle emphasizes creating products that are built to last. For SMBs, this means moving away from planned obsolescence and focusing on quality and robustness. Durable products reduce the frequency of replacements, decreasing resource consumption and waste generation. This can translate to customer loyalty and reduced warranty costs for SMBs.

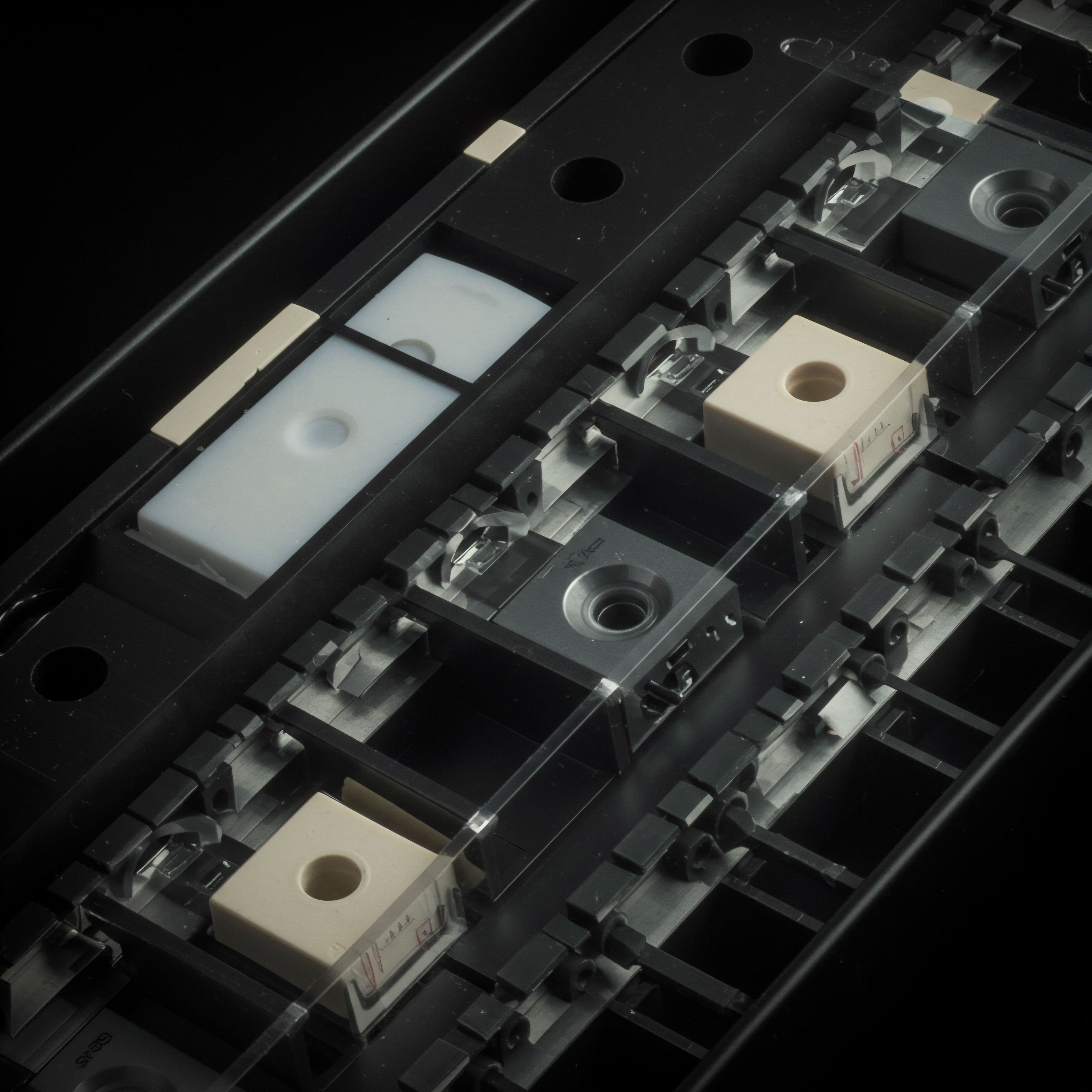

- Design for Disassembly and Reassembly ● Products should be designed in a way that they can be easily disassembled at the end of their life. This facilitates the recovery of components and materials for reuse, remanufacturing, or recycling. For SMBs, this might involve modular product design, standardized components, and clear instructions for disassembly. This approach can open up opportunities for product refurbishment and resale, creating new revenue streams.

- Resource Efficiency and Waste Reduction ● Circular Manufacturing aims to minimize resource input and waste output throughout the entire product lifecycle. For SMBs, this translates to optimizing material usage, reducing energy consumption in manufacturing processes, and minimizing waste generation in operations. Implementing lean manufacturing principles and adopting technologies that enhance resource efficiency Meaning ● Resource Efficiency for SMBs: Optimizing resource use to maximize value, minimize waste, and ensure sustainable growth. are key strategies.

- Product as a Service (PaaS) ● Instead of selling products outright, SMBs can offer products as a service. This shifts the focus from ownership to access, incentivizing manufacturers to design durable and long-lasting products that can be repeatedly used and maintained. PaaS models can create stable recurring revenue streams for SMBs and foster stronger customer relationships.

- Material Recovery and Recycling ● When products reach the end of their useful life, materials should be recovered and recycled back into the production cycle. For SMBs, this involves establishing systems for collecting used products, sorting materials, and partnering with recycling facilities. Utilizing recycled materials in manufacturing can reduce reliance on virgin resources and lower material costs.

The Description of Circular Manufacturing extends beyond just recycling. It’s a holistic approach that encompasses the entire value chain, from product design to end-of-life management. For SMBs, adopting circular practices requires a strategic shift in mindset and operations, but the potential benefits in terms of cost savings, innovation, and sustainability are substantial.

Circular Manufacturing Vs. Linear Manufacturing ● A Table Comparison for SMBs

To further Clarify the Meaning and implications of Circular Manufacturing for SMBs, a comparative table against the traditional linear model is beneficial.

| Feature Resource Use |

| Linear Manufacturing Take-Make-Dispose ● Relies heavily on virgin raw materials. |

| Circular Manufacturing Closed-Loop ● Maximizes use of recycled and renewable resources. |

| SMB Relevance Reduces vulnerability to raw material price fluctuations; potential cost savings. |

| Feature Product Design |

| Linear Manufacturing Designed for single use or limited lifespan; planned obsolescence. |

| Circular Manufacturing Designed for durability, disassembly, reuse, and recycling. |

| SMB Relevance Enhances product value and customer loyalty; opens up new service opportunities. |

| Feature Waste Generation |

| Linear Manufacturing Significant waste at end-of-life; landfill disposal. |

| Circular Manufacturing Minimal waste; materials recovered and reused or recycled. |

| SMB Relevance Reduces waste disposal costs; improves environmental compliance. |

| Feature Business Model |

| Linear Manufacturing Primarily focused on product sales. |

| Circular Manufacturing Can include product-as-a-service, leasing, and refurbishment models. |

| SMB Relevance Diversifies revenue streams; fosters stronger customer relationships. |

| Feature Environmental Impact |

| Linear Manufacturing High environmental footprint; contributes to resource depletion and pollution. |

| Circular Manufacturing Lower environmental footprint; promotes resource conservation and pollution reduction. |

| SMB Relevance Enhances brand reputation; meets growing consumer demand for sustainability. |

| Feature Long-Term Viability |

| Linear Manufacturing Increasingly unsustainable due to resource scarcity and environmental concerns. |

| Circular Manufacturing More sustainable and resilient in the face of resource constraints and environmental regulations. |

| SMB Relevance Ensures long-term business competitiveness and resilience. |

This table provides a clear Delineation between linear and circular approaches, highlighting the specific relevance and potential advantages for SMBs. The Specification of these differences is crucial for SMBs to understand the strategic shift required and the potential benefits of adopting circular manufacturing practices.

Initial Steps for SMBs to Embrace Circularity

For SMBs looking to embark on the journey towards Circular Manufacturing, understanding the initial steps is crucial. This Explication provides a starting point for implementation.

- Conduct a Circularity Assessment ● Begin by assessing your current operations to identify areas where circular principles can be applied. This involves analyzing material flows, waste streams, and product lifecycles. For SMBs, this assessment can be relatively simple, focusing on key areas of impact.

- Prioritize Quick Wins ● Identify and implement circular initiatives that offer immediate benefits and are relatively easy to implement. This could include improving waste segregation for better recycling, optimizing packaging to reduce material usage, or implementing energy-efficient practices.

- Engage Employees and Stakeholders ● Circularity requires a company-wide commitment. Engage employees in the process, educate them about circular principles, and encourage their participation in circular initiatives. Also, engage with suppliers and customers to build a circular ecosystem.

- Explore Product Design Improvements ● Start thinking about how to design products for durability, disassembly, and recyclability. This might involve small changes initially, such as using more recyclable materials or simplifying product designs.

- Invest in Automation and Technology (Strategically) ● While full-scale automation might be a longer-term goal, SMBs can strategically invest in technologies that support circularity, such as software for material tracking, sensors for waste monitoring, or basic automation for sorting and disassembly. Start with targeted investments that offer clear ROI in terms of resource efficiency or waste reduction.

These initial steps provide a practical roadmap for SMBs to begin their transition towards Circular Manufacturing. The Statement that circularity is a complex undertaking is true, but by breaking it down into manageable steps and focusing on practical implementation, SMBs can gradually realize the benefits of this transformative approach. The Designation of these steps as ‘initial’ emphasizes that this is a journey, not a destination, and continuous improvement is key.

Intermediate

Building upon the fundamental understanding of Circular Manufacturing, we now delve into an intermediate level of complexity, exploring the strategic implications and implementation challenges for SMBs in greater depth. At this stage, it’s crucial to move beyond basic definitions and understand the nuanced Meaning of circularity within the context of SMB growth, automation, and implementation strategies. The Significance of Circular Manufacturing for SMBs extends beyond mere environmental compliance; it represents a strategic pathway to enhanced competitiveness, innovation, and long-term resilience.

Circular Manufacturing, in its intermediate interpretation, is not just about recycling; it’s about fundamentally rethinking business models and operational processes to create closed-loop systems that drive both economic and environmental value.

The Explanation at this level requires a more sophisticated understanding of the business drivers and barriers to circularity for SMBs. While the Description in the fundamental section focused on basic principles, here we need to Clarify the strategic Intention behind adopting circular practices. For SMBs, the Connotation of Circular Manufacturing is often associated with increased complexity and cost.

However, a deeper analysis reveals that strategic implementation can lead to significant cost savings, new revenue streams, and enhanced brand value. The Implication is that SMBs need to approach circularity not as a burden, but as a strategic opportunity.

Strategic Drivers for Circular Manufacturing in SMBs

Several strategic drivers are compelling SMBs to consider and implement Circular Manufacturing practices. Understanding these drivers is essential for developing effective implementation strategies.

- Resource Security and Price Volatility ● SMBs are often more vulnerable to fluctuations in raw material prices and supply chain disruptions than larger corporations. Circular Manufacturing offers a buffer against these risks by reducing reliance on virgin resources and promoting the use of recycled and secondary materials. This enhanced resource security can lead to more stable production costs and improved supply chain resilience for SMBs.

- Enhanced Brand Reputation Meaning ● Brand reputation, for a Small or Medium-sized Business (SMB), represents the aggregate perception stakeholders hold regarding its reliability, quality, and values. and Customer Demand ● Consumers are increasingly demanding sustainable products and practices. SMBs that embrace Circular Manufacturing can enhance their brand reputation and attract environmentally conscious customers. This can be a significant competitive advantage, particularly in markets where sustainability is a key purchasing criterion. The Import of a strong sustainability narrative is growing rapidly in consumer markets.

- Regulatory Pressures and Compliance ● Environmental regulations are becoming stricter globally, and SMBs are increasingly subject to these regulations. Circular Manufacturing can help SMBs comply with environmental regulations and avoid potential penalties. Proactive adoption of circular practices can also position SMBs favorably for future regulatory changes. The Purport of new regulations is often to incentivize circular economy Meaning ● A regenerative economic model for SMBs, maximizing resource use and minimizing waste for sustainable growth. models.

- Innovation and New Business Opportunities ● The transition to Circular Manufacturing can drive innovation in product design, manufacturing processes, and business models. SMBs that embrace circularity are often forced to rethink their operations, leading to the development of new products, services, and processes. This can open up new market opportunities and create a competitive edge. The Denotation of innovation in a circular context is often linked to resource efficiency and waste reduction.

- Cost Savings and Efficiency Gains ● While initial investments in circularity might be required, in the long run, Circular Manufacturing can lead to significant cost savings. This can be achieved through reduced material costs, lower waste disposal fees, and improved energy efficiency. For SMBs, these cost savings can be crucial for profitability and sustainability. The Substance of these savings becomes more apparent over time as circular systems mature.

These strategic drivers highlight the multifaceted Significance of Circular Manufacturing for SMBs. It’s not just about environmental responsibility; it’s about building a more resilient, innovative, and profitable business in the long term. The Essence of circularity, in this context, is strategic business advantage.

Implementation Challenges and Mitigation Strategies for SMBs

Despite the compelling drivers, SMBs face several challenges in implementing Circular Manufacturing. Understanding these challenges and developing mitigation strategies is crucial for successful implementation.

| Challenge Initial Investment Costs |

| Description Transitioning to circular practices often requires upfront investments in new technologies, processes, and infrastructure. |

| Mitigation Strategy for SMBs Phased Implementation ● Start with pilot projects and scale up gradually. Focus on low-cost, high-impact initiatives initially. Seek government grants and subsidies for circular economy projects. |

| Challenge Lack of Expertise and Knowledge |

| Description SMBs may lack the internal expertise and knowledge to design and implement circular strategies. |

| Mitigation Strategy for SMBs External Partnerships ● Collaborate with universities, research institutions, and circular economy consultants. Join industry associations and networks focused on sustainability. Utilize online resources and training programs. |

| Challenge Supply Chain Complexity |

| Description Establishing circular supply chains, particularly for recycled materials, can be complex and challenging. |

| Mitigation Strategy for SMBs Local Sourcing ● Prioritize local suppliers of recycled materials. Develop long-term relationships with suppliers to ensure quality and reliability. Explore collaborative procurement with other SMBs. |

| Challenge Market Demand Uncertainty |

| Description The market demand for circular products and services may still be developing, creating uncertainty for SMBs. |

| Mitigation Strategy for SMBs Market Research ● Conduct thorough market research to understand customer demand for circular products. Educate customers about the benefits of circularity. Develop clear value propositions for circular offerings. |

| Challenge Regulatory and Policy Barriers |

| Description Existing regulations and policies may not always support circular economy models, creating barriers for SMBs. |

| Mitigation Strategy for SMBs Advocacy and Engagement ● Engage with policymakers and industry associations to advocate for policies that support circularity. Participate in consultations and provide feedback on regulatory frameworks. |

| Challenge Automation and Technology Integration |

| Description Integrating automation and technology to support circular processes (e.g., sorting, disassembly, remanufacturing) can be complex and costly for SMBs. |

| Mitigation Strategy for SMBs Strategic Technology Adoption ● Focus on targeted automation solutions that address specific bottlenecks in circular processes. Explore affordable and scalable technologies. Leverage digital platforms for material tracking and resource management. |

This table provides a detailed Interpretation of the challenges and offers specific mitigation strategies tailored for SMBs. The Elucidation of these challenges is crucial for SMBs to realistically assess the barriers and proactively plan for overcoming them. The Delineation of mitigation strategies provides actionable steps that SMBs can take to navigate the complexities of circular implementation.

Advanced Circular Business Models for SMB Growth

Beyond basic recycling and waste reduction, SMBs can explore more advanced circular business models Meaning ● Circular Business Models redefine SMB operations towards resource efficiency and regeneration for sustainable growth. to drive growth and innovation. These models represent a deeper Sense of commitment to circularity and offer significant potential for differentiation and competitive advantage.

- Product-As-A-Service (PaaS) for SMBs ● Offering products as a service, rather than selling them outright, can create recurring revenue streams and foster stronger customer relationships. For SMBs, PaaS models can be particularly effective in sectors such as equipment rental, tool sharing, and software services. Example ● A small manufacturing company could offer ‘lighting as a service’ to businesses, providing energy-efficient lighting solutions and managing maintenance and upgrades, rather than just selling light fixtures.

- Product Life Extension and Refurbishment ● Extending the lifespan of products through repair, refurbishment, and remanufacturing can create new revenue streams and reduce waste. SMBs can establish refurbishment centers, offer repair services, and sell refurbished products at a lower price point. Example ● An electronics SMB could offer a trade-in program for old devices, refurbish them, and resell them with a warranty, targeting price-sensitive customers.

- Industrial Symbiosis and Collaboration ● Collaborating with other businesses to exchange waste streams and byproducts can create mutually beneficial circular loops. SMBs can participate in industrial symbiosis networks to find uses for their waste and source materials from other companies’ waste streams. Example ● A food processing SMB could partner with a local farm to use food waste as compost, and in turn, source produce from the farm.

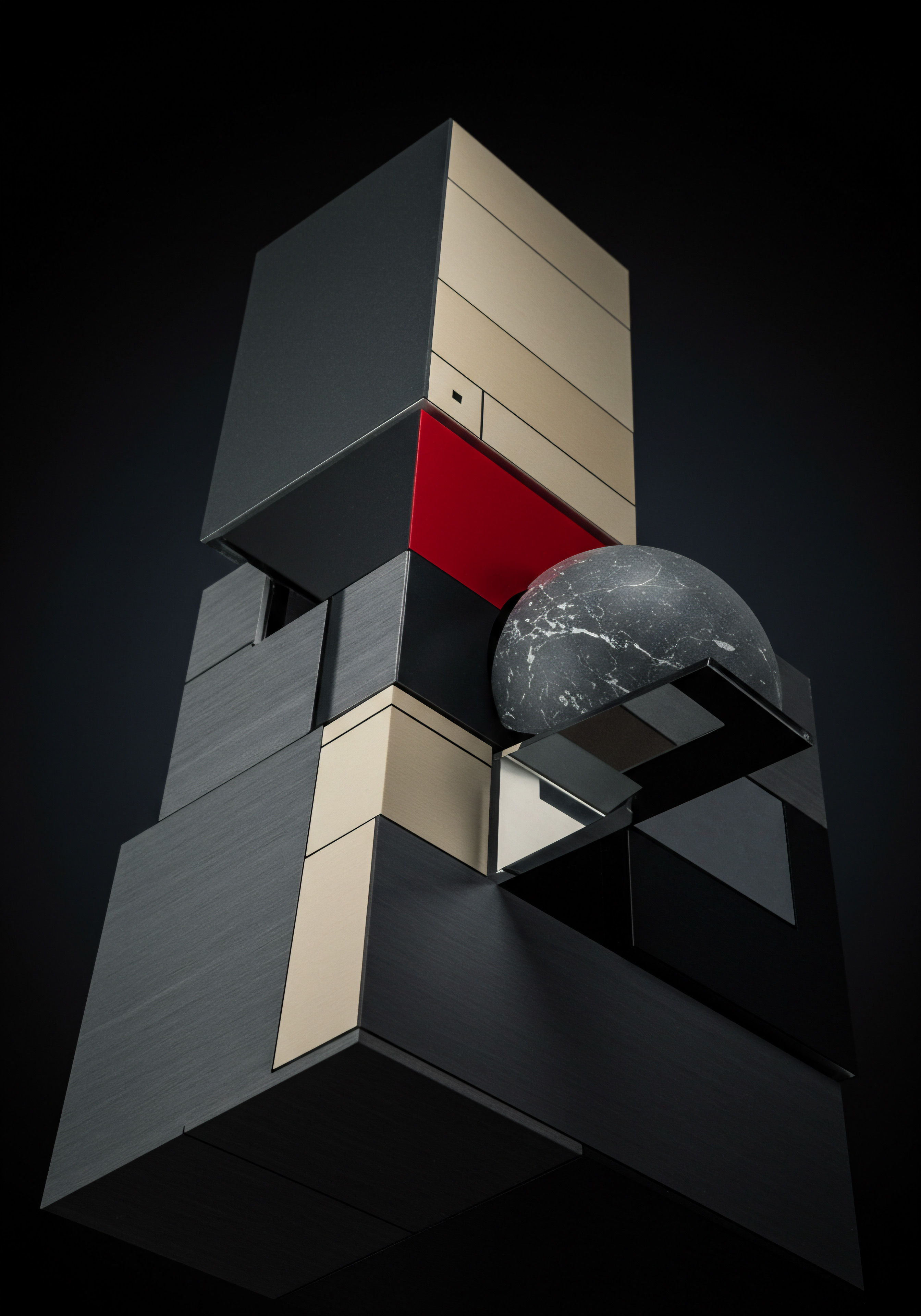

- Circular Design and Material Innovation ● Investing in circular design principles and exploring innovative materials can create products that are inherently more sustainable and circular. SMBs can focus on using recycled materials, bio-based materials, and designing for disassembly and recyclability. Example ● A furniture SMB could design furniture using recycled wood and modular components, making it easy to repair, upgrade, and recycle at the end of its life.

- Digital Platforms for Circularity ● Leveraging digital platforms and technologies can facilitate circular processes, such as material tracking, product lifecycle management, and online marketplaces for used goods. SMBs can utilize digital tools to optimize resource utilization, connect with customers for product take-back, and manage circular supply chains. Example ● An apparel SMB could use a blockchain-based platform to track the lifecycle of its garments, from raw material sourcing to end-of-life recycling, providing transparency to customers and facilitating product take-back.

These advanced business models demonstrate the potential for Circular Manufacturing to be a driver of SMB growth Meaning ● SMB Growth is the strategic expansion of small to medium businesses focusing on sustainable value, ethical practices, and advanced automation for long-term success. and innovation. The Specification of these models provides concrete examples of how SMBs can move beyond basic circular practices and embrace more transformative approaches. The Explication of each model highlights its unique value proposition and potential benefits for SMBs.

Advanced

At the advanced level, the Meaning of Circular Manufacturing transcends operational efficiency Meaning ● Maximizing SMB output with minimal, ethical input for sustainable growth and future readiness. and environmental stewardship, evolving into a complex, multi-faceted paradigm shift with profound implications for SMB growth, automation, and societal transformation. The Definition, therefore, must be rigorously constructed, drawing upon scholarly research, empirical data, and critical business analysis to capture its full Significance. Moving beyond simplistic Interpretations, we must engage with the nuanced Connotations and Implications of circularity within diverse SMB contexts, acknowledging the inherent complexities and potential contradictions.

Circular Manufacturing, in its advanced articulation, represents a systemic restructuring of industrial production and consumption, driven by ecological imperatives and enabled by technological advancements, aiming for decoupling economic growth Meaning ● Economic growth, in the context of small and medium-sized businesses, signifies a sustained increase in a firm's revenue, market share, and overall profitability, often driven by strategic adoption of automation and efficient implementation strategies. from resource depletion and environmental degradation, particularly within the dynamic and resource-constrained landscape of SMBs.

This advanced Statement of Circular Manufacturing necessitates a critical Explication, drawing upon interdisciplinary perspectives from economics, environmental science, engineering, and sociology. The Designation of circularity as a ‘paradigm shift’ underscores its transformative potential, requiring a fundamental rethinking of established business models and industrial practices. The Elucidation of its Essence demands a rigorous examination of its theoretical underpinnings, empirical evidence, and practical applications, particularly within the SMB sector, which often operates under unique constraints and opportunities.

Redefining Circular Manufacturing ● An Advanced Perspective

Based on reputable business research and data, particularly from domains like Google Scholar, we can redefine Circular Manufacturing from an advanced perspective. This redefinition involves analyzing diverse perspectives, acknowledging multi-cultural business aspects, and examining cross-sectorial business influences. For the purpose of in-depth analysis, we will focus on the cross-sectorial influence of Digital Technologies and Automation on the meaning and implementation of Circular Manufacturing for SMBs.

Advanced Definition and Meaning of Circular Manufacturing (Refined) ●

Circular Manufacturing is a socio-technical system characterized by the deliberate design, implementation, and optimization of closed-loop material and energy flows within and across organizational boundaries, leveraging digital technologies and automation to maximize resource productivity, minimize waste generation, and decouple economic value creation from linear resource consumption. This system is context-dependent, influenced by sector-specific dynamics, regional regulations, cultural norms, and the evolving landscape of technological innovation. For SMBs, the successful adoption of Circular Manufacturing necessitates a strategic alignment with their specific capabilities, market positioning, and resource constraints, requiring a phased and adaptive implementation approach.

This refined Definition emphasizes several key aspects:

- Socio-Technical System ● Acknowledges that Circular Manufacturing is not merely a technological or engineering challenge, but also a social and organizational one. It requires changes in mindset, organizational culture, and stakeholder collaboration. For SMBs, this means fostering a circular culture within their teams and engaging with customers and suppliers in new ways.

- Closed-Loop Material and Energy Flows ● Highlights the core principle of minimizing resource leakage and maximizing resource recirculation. This goes beyond simple recycling and encompasses strategies like reuse, remanufacturing, and product life extension. For SMBs, this requires a detailed understanding of their material and energy flows and identifying opportunities for closure.

- Digital Technologies and Automation ● Recognizes the enabling role of digital technologies and automation in facilitating circular processes. This includes technologies like IoT sensors for material tracking, AI-powered algorithms for waste sorting, and robotic systems for disassembly and remanufacturing. For SMBs, strategic adoption of these technologies is crucial for scaling circular operations and enhancing efficiency.

- Decoupling Economic Growth from Linear Resource Consumption ● Articulates the fundamental goal of Circular Manufacturing ● to achieve economic prosperity without depleting natural resources and degrading the environment. This is particularly relevant for SMBs operating in resource-constrained environments or facing increasing pressure to reduce their environmental footprint.

- Context-Dependent and Adaptive Implementation ● Emphasizes that there is no one-size-fits-all approach to Circular Manufacturing. Implementation strategies must be tailored to the specific context of each SMB, considering sector-specific dynamics, regional regulations, and resource availability. Adaptability and iterative improvement are key to successful implementation.

The Interpretation of this advanced definition reveals a more complex and nuanced understanding of Circular Manufacturing. It is not simply about ‘being green’ but about fundamentally transforming industrial systems to be more resilient, efficient, and sustainable. For SMBs, this means embracing circularity as a strategic imperative, not just an operational add-on.

Cross-Sectorial Business Influences ● Digital Technologies and Automation in SMB Circular Manufacturing

The cross-sectorial influence of Digital Technologies and Automation is profoundly shaping the landscape of Circular Manufacturing for SMBs. These technologies are not merely tools for optimization; they are enablers of fundamentally new circular business models and operational paradigms. Analyzing this influence requires a deep dive into specific technological applications and their business outcomes for SMBs.

Impact of Digital Technologies and Automation on SMB Circular Manufacturing ●

- Enhanced Material Tracking and Transparency (IoT and Blockchain) ● Description ● Internet of Things (IoT) sensors and blockchain technologies enable real-time tracking of materials throughout the product lifecycle, from raw material sourcing to end-of-life management. This provides unprecedented transparency and traceability, crucial for verifying the circularity of products and supply chains. SMB Application ● SMBs can use IoT sensors to track inventory of reusable components, monitor waste streams, and optimize material flows. Blockchain can be used to verify the provenance of recycled materials and build trust with customers regarding the sustainability of their products. Business Outcome ● Improved resource efficiency, reduced material losses, enhanced brand reputation through transparency, and potential for premium pricing for circular products.

- AI-Powered Waste Sorting and Resource Recovery (Artificial Intelligence and Robotics) ● Description ● Artificial Intelligence (AI) algorithms and robotic systems are revolutionizing waste sorting and resource recovery processes. AI can analyze images and sensor data to identify and separate different types of waste with high accuracy and speed. Robotics can automate the physical sorting and disassembly of products, making resource recovery more efficient and cost-effective. SMB Application ● SMBs can deploy AI-powered sorting systems in their manufacturing facilities to separate and recover valuable materials from waste streams. Robotic disassembly systems can be used to dismantle end-of-life products for component reuse and material recycling. Business Outcome ● Reduced waste disposal costs, increased revenue from recovered materials, improved resource security, and enhanced environmental performance.

- Digital Platforms for Circular Business Models (E-Commerce and Data Analytics) ● Description ● Digital platforms, including e-commerce marketplaces and data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. tools, are facilitating new circular business models such as product-as-a-service, sharing economy platforms, and online marketplaces for used goods. These platforms connect producers and consumers in new ways, enabling efficient resource sharing and product lifecycle extension. SMB Application ● SMBs can leverage e-commerce platforms to offer product-as-a-service models, rent out equipment, or sell refurbished products online. Data analytics can be used to optimize product design for durability and recyclability, predict product lifespan, and manage reverse logistics for product take-back. Business Outcome ● New revenue streams from circular business models, enhanced customer relationships Meaning ● Customer Relationships, within the framework of SMB expansion, automation processes, and strategic execution, defines the methodologies and technologies SMBs use to manage and analyze customer interactions throughout the customer lifecycle. through service offerings, improved product design based on data-driven insights, and increased market reach through digital platforms.

- Additive Manufacturing for Circular Design and Production (3D Printing) ● Description ● Additive Manufacturing (3D printing) offers significant potential for circular design and production. It enables on-demand manufacturing, reducing material waste and inventory. It also facilitates the production of customized and modular products that are easier to repair, upgrade, and recycle. SMB Application ● SMBs can use 3D printing to produce spare parts on demand, reducing the need for large inventories and extending product lifespan. They can also design modular products that can be easily customized and upgraded using 3D printing. Business Outcome ● Reduced material waste in production, lower inventory costs, enhanced product customization and flexibility, and improved product durability and reparability.

- Cloud Computing and Data Management for Circular Systems (Cloud Services and Big Data) ● Description ● Cloud computing and big data analytics provide the infrastructure and tools to manage the complex data flows and information sharing required for circular systems. Cloud platforms enable collaboration and data exchange across supply chains, facilitating material tracking, resource optimization, and lifecycle assessment. SMB Application ● SMBs can leverage cloud-based platforms to manage their circular supply chains, track material flows, and share data with suppliers and customers. Big data analytics can be used to identify patterns and insights from circular data, optimizing resource utilization and improving decision-making. Business Outcome ● Improved supply chain efficiency, enhanced collaboration and information sharing, data-driven decision-making for circularity, and reduced IT infrastructure costs through cloud services.

These examples Delineate the transformative potential of digital technologies and automation for Circular Manufacturing in SMBs. The Specification of each technology and its application provides concrete insights into how SMBs can leverage these tools to implement circular strategies. The Explication of business outcomes highlights the tangible benefits that SMBs can achieve through strategic technology adoption. The Import of these technologies is not merely operational improvement but the creation of fundamentally new circular business models and value propositions.

Long-Term Business Consequences and Success Insights for SMBs in Circular Manufacturing

The long-term business consequences Meaning ● Business Consequences: The wide-ranging impacts of business decisions on SMB operations, stakeholders, and long-term sustainability. of embracing Circular Manufacturing for SMBs are profound and far-reaching. Success in this domain requires a strategic vision, a commitment to innovation, and an adaptive approach to implementation. Analyzing historical patterns and predicting future developments provides valuable insights for SMBs seeking to thrive in a circular economy.

Long-Term Business Consequences and Success Insights ●

- Enhanced Competitive Advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. and Market Differentiation ● Consequence ● SMBs that proactively adopt Circular Manufacturing can gain a significant competitive advantage by differentiating themselves in the market. Consumers are increasingly seeking sustainable products and services, and SMBs with strong circular credentials can attract and retain these customers. Success Insight ● Focus on building a strong brand narrative around circularity, clearly communicating the environmental and social benefits of your products and services. Obtain relevant certifications and labels to validate your circular claims and build trust with customers.

- Increased Resilience to Resource Scarcity and Price Volatility ● Consequence ● In a world of increasing resource scarcity and price volatility, Circular Manufacturing provides SMBs with greater resilience. By reducing reliance on virgin resources and diversifying material sources through recycled and secondary materials, SMBs can mitigate supply chain risks and stabilize production costs. Success Insight ● Develop robust circular supply chains, prioritizing local and regional sources of recycled materials. Invest in material diversification strategies and explore alternative materials to reduce dependence on critical resources.

- Innovation and New Product/Service Development ● Consequence ● The transition to Circular Manufacturing drives innovation across all aspects of the business, from product design to business models. SMBs that embrace circularity are more likely to develop new and innovative products and services that meet the evolving needs of a sustainable economy. Success Insight ● Foster a culture of innovation within your organization, encouraging experimentation and risk-taking in circular design and business model development. Collaborate with research institutions and technology providers to access cutting-edge knowledge and technologies.

- Improved Operational Efficiency and Cost Savings ● Consequence ● While initial investments may be required, in the long run, Circular Manufacturing can lead to significant operational efficiency gains and cost savings. Reduced material costs, lower waste disposal fees, and improved energy efficiency contribute to enhanced profitability and financial sustainability. Success Insight ● Implement a phased approach to circularity, starting with low-cost, high-impact initiatives that deliver quick wins and demonstrate tangible cost savings. Continuously monitor and optimize circular processes to maximize efficiency and minimize waste.

- Enhanced Stakeholder Engagement and Reputation ● Consequence ● Embracing Circular Manufacturing enhances stakeholder engagement and improves corporate reputation. Customers, employees, investors, and communities increasingly value businesses that are committed to sustainability and social responsibility. A strong circularity performance can attract talent, improve employee morale, and enhance investor confidence. Success Insight ● Engage proactively with stakeholders, communicating your circularity vision and progress transparently. Incorporate stakeholder feedback into your circularity strategy and build collaborative partnerships to amplify your impact.

These long-term consequences and success insights underscore the strategic Significance of Circular Manufacturing for SMBs. The Essence of success lies in embracing circularity not as a compliance exercise but as a core business strategy, driving innovation, resilience, and long-term value creation. The Purport of this advanced analysis is to provide SMBs with a deeper understanding of the transformative potential of circularity and to equip them with the knowledge and insights needed to navigate this complex but ultimately rewarding journey.

The Meaning of Circular Manufacturing for SMBs, therefore, is not static but evolves with technological advancements, societal expectations, and economic realities. At its core, it represents a pathway to a more sustainable and prosperous future, where economic growth and environmental stewardship are not mutually exclusive but mutually reinforcing. For SMBs, embracing this paradigm shift is not just an ethical imperative but a strategic necessity for long-term success and resilience in the 21st century.