Fundamentals

For small to medium-sized businesses (SMBs), the concept of a Circular Economy SMB Model might initially seem complex or only relevant to large corporations. However, at its core, it’s a straightforward idea about doing business in a smarter, more sustainable way. Imagine a traditional business model ● often called ‘linear’ ● as a straight line ● resources are taken from the earth, products are made, used, and then thrown away. This ‘take-make-dispose’ approach is increasingly recognized as unsustainable due to resource depletion and environmental impact.

A Circular Economy, in contrast, aims to close this loop, making it a circle. Instead of disposal, resources are kept in use for as long as possible, extracting the maximum value from them, then recovering and regenerating products and materials at the end of each service life.

Circular Economy SMB Models are about shifting from a linear ‘take-make-dispose’ approach to a circular ‘reduce-reuse-recycle’ system within SMB operations.

For SMBs, adopting a Circular Economy SMB Model doesn’t necessarily mean a complete overhaul overnight. It’s about gradually integrating circular principles into their existing business operations. This could involve simple steps like reducing waste, reusing materials, or offering product take-back programs.

The benefits for SMBs can be significant, ranging from cost savings and enhanced brand reputation Meaning ● Brand reputation, for a Small or Medium-sized Business (SMB), represents the aggregate perception stakeholders hold regarding its reliability, quality, and values. to new market opportunities and increased resilience. Understanding the fundamental principles is the first step for any SMB looking to explore this increasingly important business paradigm.

Understanding the Core Principles of Circular Economy for SMBs

The circular economy Meaning ● A regenerative economic model for SMBs, maximizing resource use and minimizing waste for sustainable growth. framework is built upon several key principles, all highly relevant and adaptable for SMB operations. These principles guide how SMBs can rethink their processes and offerings to become more circular. Let’s break down some of the most fundamental ones:

- Design for Durability and Longevity ● This principle emphasizes creating products that last longer and are more durable. For SMBs, this can mean investing in higher quality materials, designing for repairability, and offering extended warranties. Durable products reduce the need for frequent replacements, minimizing resource consumption and waste. Consider a small furniture maker that shifts from using low-cost, short-life materials to sustainably sourced, high-quality wood. Their furniture becomes more durable, requiring less frequent replacement, and appealing to customers seeking long-lasting value. This also opens opportunities for repair and refurbishment services, creating new revenue streams.

- Resource Efficiency and Waste Reduction ● Circular economy fundamentally aims to minimize waste and maximize resource utilization. For SMBs, this can translate into various operational efficiencies. It could involve optimizing production processes to reduce material waste, implementing waste segregation and recycling programs, or even finding innovative ways to utilize by-products. A small bakery, for instance, can reduce food waste by carefully managing inventory, using leftover bread for croutons or animal feed, and composting organic waste. These actions not only reduce waste disposal costs but also enhance resource efficiency.

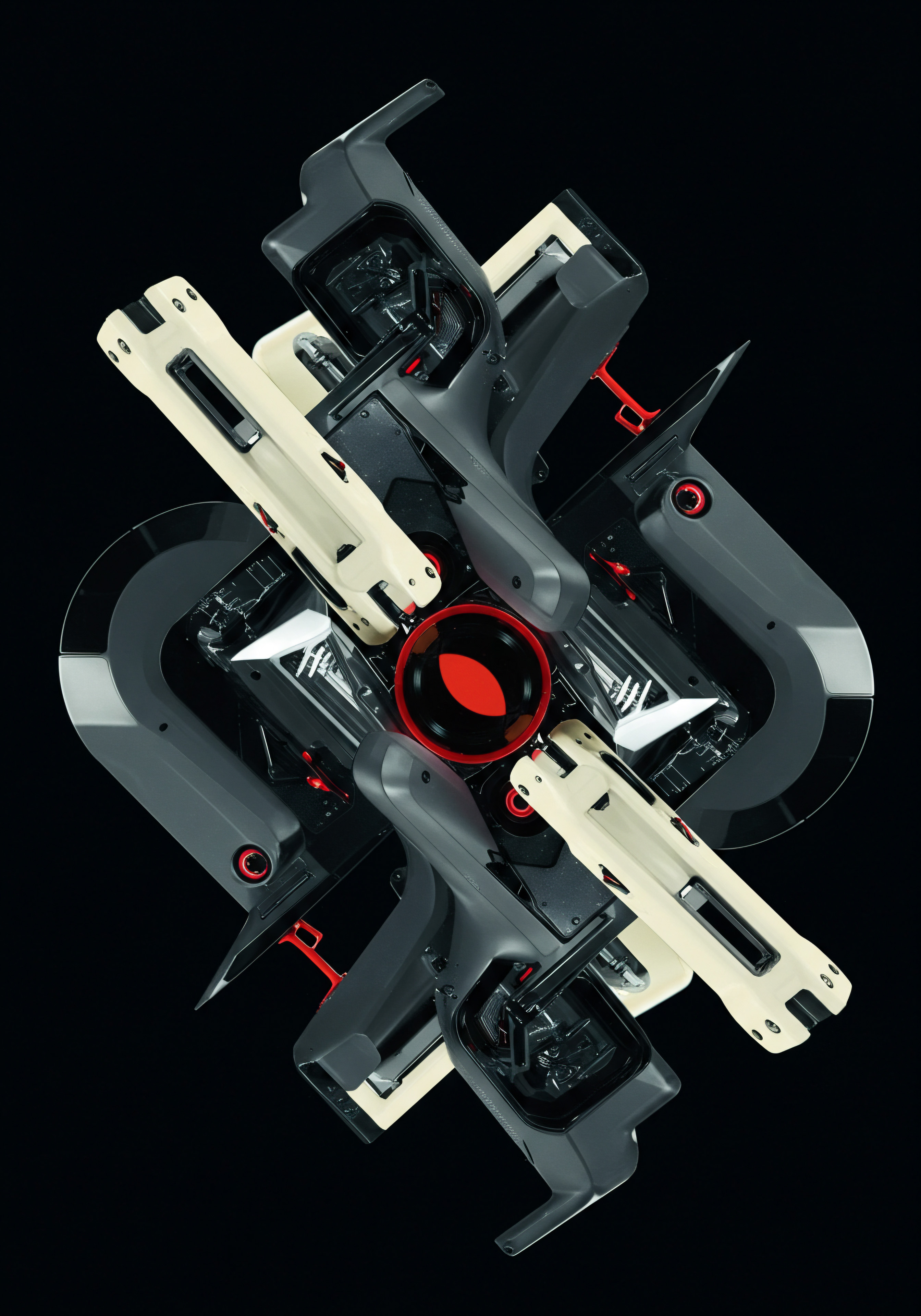

- Product Life Extension and Reuse ● Extending the lifespan of products is a core tenet of the circular economy. SMBs can achieve this through various strategies like offering repair services, refurbishment programs, or facilitating product reuse through take-back schemes or second-hand sales. A small electronics repair shop already operates on this principle, but they can further embrace circularity by actively promoting repair over replacement, offering trade-in programs for old devices, and reselling refurbished electronics. This not only extends product life but also creates customer loyalty and new revenue streams from repair and refurbishment services.

- Recycling and Material Recovery ● While reducing and reusing are prioritized, recycling remains a crucial component of the circular economy. SMBs can actively participate in recycling by designing products for recyclability, using recycled materials in their production, and ensuring proper disposal and collection of recyclable waste. A small clothing boutique could choose to stock brands that use recycled fabrics and design garments for easy disassembly and recycling at the end of their life. They can also partner with textile recycling programs to facilitate responsible disposal and material recovery. This demonstrates a commitment to environmental responsibility and appeals to eco-conscious consumers.

- Product as a Service (PaaS) Models ● Shifting from selling products to offering services can be a powerful circular strategy. In PaaS models, customers pay for the use of a product rather than owning it outright. This incentivizes SMBs to design durable, high-quality products that are easily maintained and upgraded, as they retain ownership and responsibility for the product’s lifecycle. A small office equipment supplier could transition from selling printers to offering printing services, charging customers based on usage. This model encourages them to provide reliable, long-lasting printers and manage their maintenance and eventual recycling, aligning their interests with product longevity and resource efficiency.

Initial Steps for SMBs Embracing Circularity

Embarking on a circular economy journey doesn’t require massive upfront investments or radical changes for SMBs. It can begin with small, manageable steps that gradually build momentum and demonstrate tangible benefits. Here are some practical initial steps SMBs can consider:

- Waste Audit and Assessment ● Conduct a thorough audit of current waste streams. Identify the types and quantities of waste generated across different operations. This assessment provides a baseline and highlights areas where waste reduction efforts can be most impactful. For example, an office-based SMB might discover significant paper waste, prompting them to implement digital document management and encourage double-sided printing.

- Optimize Resource Use ● Analyze current resource consumption patterns. Look for opportunities to reduce material inputs, energy usage, and water consumption. This could involve switching to energy-efficient equipment, implementing water-saving measures, or optimizing packaging to minimize material use. A small restaurant could analyze its food procurement and preparation processes to minimize ingredient waste and optimize cooking methods to reduce energy consumption.

- Explore Reuse and Repurposing Opportunities ● Identify materials or products currently being discarded that could be reused or repurposed within the business. This could involve reusing packaging materials, repurposing furniture, or finding creative uses for by-products. A small retail store could reuse cardboard boxes for storage or in-store displays, reducing packaging waste and creating a rustic aesthetic.

- Engage Employees and Customers ● Circularity is a collaborative effort. Educate employees about circular economy principles and involve them in identifying and implementing circular initiatives. Communicate circular efforts to customers to enhance brand image and build customer loyalty. A small coffee shop could engage employees in waste segregation and recycling efforts and inform customers about their commitment to sustainable practices through signage and social media.

- Seek Partnerships and Collaboration ● Explore opportunities to collaborate with other businesses, suppliers, or organizations to advance circular economy initiatives. This could involve partnering with local recyclers, joining industry associations focused on sustainability, or collaborating with suppliers to source recycled materials. A small construction company could partner with a demolition firm to source reclaimed building materials, reducing reliance on virgin resources and supporting local circular ecosystems.

By taking these initial steps, SMBs can begin to integrate circular economy principles into their operations, laying the foundation for more comprehensive circular strategies in the future. The key is to start small, focus on practical actions, and continuously seek opportunities for improvement and expansion.

| Strategy Waste Reduction |

| Description Minimizing waste generation at the source through process optimization and material efficiency. |

| SMB Example A bakery optimizing ingredient usage to reduce food spoilage. |

| Benefits for SMB Cost savings on waste disposal, reduced material costs, improved operational efficiency. |

| Strategy Reuse & Repurposing |

| Description Finding new uses for materials or products that would otherwise be discarded. |

| SMB Example A retail store reusing cardboard boxes for storage and displays. |

| Benefits for SMB Reduced material costs, lower waste disposal fees, enhanced brand image. |

| Strategy Recycling |

| Description Ensuring proper collection and processing of recyclable materials. |

| SMB Example An office implementing a comprehensive paper and plastic recycling program. |

| Benefits for SMB Reduced waste disposal costs, compliance with regulations, positive environmental impact. |

| Strategy Durable Product Design |

| Description Creating products designed for longevity and repairability. |

| SMB Example A furniture maker using high-quality, sustainable wood for durable furniture. |

| Benefits for SMB Customer satisfaction, reduced warranty claims, potential for repair service revenue. |

| Strategy Product-as-a-Service |

| Description Offering product functionality as a service rather than selling the product itself. |

| SMB Example An office equipment supplier offering printing services instead of selling printers. |

| Benefits for SMB Recurring revenue streams, stronger customer relationships, incentivized product durability. |

Intermediate

Building upon the foundational understanding of Circular Economy SMB Models, the intermediate level delves into more nuanced strategies and considerations for SMBs seeking deeper integration. At this stage, SMBs move beyond basic waste reduction and recycling to explore more transformative approaches that can fundamentally reshape their business models and create competitive advantages. The focus shifts towards strategically embedding circularity into core business functions, from product design and supply chain management to customer engagement and new service offerings. This transition requires a more sophisticated understanding of circular economy principles and a willingness to innovate and adapt business processes.

Moving to an intermediate level of Circular Economy SMB Meaning ● Circular Economy SMB: Sustainable business approach for SMEs focusing on resource efficiency, waste reduction, and circularity for economic and environmental benefits. Models involves strategically embedding circularity into core business functions like product design, supply chain, and customer engagement.

For SMBs at the intermediate stage, circularity is no longer just an add-on or a ‘nice-to-have’; it becomes an integral part of their business strategy. This involves exploring various circular business models Meaning ● Circular Business Models redefine SMB operations towards resource efficiency and regeneration for sustainable growth. that align with their industry, capabilities, and market opportunities. It also necessitates a deeper analysis of the value chain, identifying key leverage points for circular interventions and considering the broader ecosystem in which the SMB operates. Furthermore, at this level, SMBs begin to explore the potential of automation and technology to enhance their circular economy initiatives, improving efficiency, scalability, and data-driven decision-making.

Exploring Advanced Circular Economy Business Models for SMBs

Beyond the foundational principles, several advanced circular business models are particularly relevant and impactful for SMBs looking to deepen their circularity journey. These models offer diverse approaches to capturing value from circularity, ranging from optimizing resource loops to creating entirely new service-based offerings:

- Product Life Extension Models ● Building on basic repair and reuse, advanced life extension models involve more proactive and systematic approaches to prolonging product lifecycles. This includes designing for modularity and upgradability, offering comprehensive maintenance contracts, and actively managing product lifecycles through take-back programs and refurbishment centers. A small appliance manufacturer could design appliances with modular components that can be easily upgraded or replaced, offer subscription-based maintenance services, and operate a refurbishment facility to extend the life of returned appliances. This creates long-term customer relationships and reduces the environmental impact of appliance disposal.

- Sharing Economy and Collaborative Consumption Models ● These models focus on maximizing product utilization by enabling shared access and collaborative consumption. For SMBs, this can involve creating rental or leasing services, establishing product pools or sharing platforms, or facilitating peer-to-peer sharing within their customer base. A small tool rental company operates on a sharing economy model, but they could expand by creating a digital platform that connects individuals and businesses needing tools with those who have underutilized tools to rent out. This maximizes tool utilization, reduces the need for individual ownership, and creates a community-based circular ecosystem.

- Circular Supply Chain and Sustainable Sourcing ● At the intermediate level, circularity extends to the entire supply chain. This involves actively sourcing recycled and renewable materials, prioritizing suppliers with strong sustainability practices, and designing products and packaging for closed-loop material flows. A small fashion brand could commit to sourcing only organic or recycled cotton, working with suppliers who adhere to fair labor and environmental standards, and designing clothing that is easily recyclable or compostable at the end of its life. This creates a more resilient and ethical supply chain and appeals to environmentally and socially conscious consumers.

- Waste as a Resource and Industrial Symbiosis ● This model views waste not as a problem but as a valuable resource. SMBs can explore opportunities to utilize waste streams from their own operations or from other businesses as inputs for new products or processes. Industrial symbiosis involves collaborative partnerships where waste from one industry becomes a resource for another. A small brewery could partner with a local farm to provide spent grain as animal feed or fertilizer, and in turn, source hops or other ingredients from the farm. This creates a symbiotic relationship, reduces waste for the brewery, and provides valuable resources for the farm, fostering local circularity.

- Product-Service Systems (PSS) and Performance Economy ● Moving beyond basic PaaS, PSS models offer integrated solutions that combine products and services to deliver specific outcomes or performance. The performance economy emphasizes selling results or performance rather than physical products, further incentivizing durability and resource efficiency. A small lighting company could offer ‘lighting as a service’ to businesses, charging them for lumens of light delivered rather than selling light fixtures. This incentivizes them to install energy-efficient, long-lasting lighting systems and manage their maintenance and upgrades, aligning their interests with energy conservation and product longevity.

Automation and Technology for Enhanced Circularity in SMBs

Automation and digital technologies play an increasingly crucial role in enabling and scaling circular economy initiatives within SMBs. These technologies can enhance efficiency, improve data visibility, and facilitate new circular business models. Here are some key areas where automation and technology can be leveraged:

- Supply Chain Traceability and Transparency ● Blockchain and IoT technologies can be used to track materials and products throughout the supply chain, providing transparency and verifying the origin and recycled content of materials. This is particularly valuable for SMBs sourcing recycled materials or wanting to demonstrate the circularity of their products. For instance, a small furniture maker using recycled plastic could use blockchain to track the plastic’s origin, processing, and incorporation into their furniture, providing verifiable proof of its recycled content to customers.

- Waste Management and Sorting Automation ● Automated waste sorting systems using AI and robotics can significantly improve the efficiency and accuracy of waste segregation and recycling processes. This is crucial for SMBs aiming to maximize material recovery and reduce contamination in recycling streams. A small waste management company could invest in automated sorting technology to improve the efficiency of their recycling facility, enabling them to process a wider range of materials and increase material recovery rates.

- Digital Platforms for Sharing and Reuse ● Online platforms and mobile apps can facilitate sharing economy models, connecting users with products or services for rent, lease, or exchange. These platforms can streamline logistics, manage transactions, and build communities around shared resources. A small business renting out bicycles could develop a mobile app that allows customers to easily locate, rent, and return bikes, improving accessibility and user experience for their sharing service.

- Data Analytics for Circularity Optimization ● Data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. and machine learning can be applied to analyze material flows, identify waste hotspots, and optimize circular processes. This data-driven approach enables SMBs to make informed decisions about resource management, product design, and circular business model implementation. A small clothing manufacturer could use data analytics to track fabric waste in their production process, identify patterns, and optimize cutting techniques to minimize waste and improve material utilization.

- 3D Printing and Distributed Manufacturing ● 3D printing technologies enable on-demand and localized production, reducing transportation costs and minimizing waste associated with traditional manufacturing. This can facilitate circular business models by enabling SMBs to produce spare parts on demand, customize products, and utilize recycled materials in 3D printing feedstock. A small repair shop could use 3D printing to produce replacement parts for appliances or equipment, extending product lifecycles and reducing reliance on spare parts from distant suppliers.

Overcoming Intermediate Challenges in Circular Economy Implementation for SMBs

While the intermediate stage offers significant opportunities, SMBs may encounter specific challenges in implementing more advanced circular economy models. Addressing these challenges requires strategic planning, resourcefulness, and a commitment to overcoming obstacles:

- Initial Investment and Financial Constraints ● Transitioning to more circular models may require upfront investments in new technologies, processes, or infrastructure. SMBs often face financial constraints and may need to explore innovative financing mechanisms, such as green loans, grants, or crowdfunding, to support these investments. Seeking government incentives and exploring collaborative funding models can also alleviate financial burdens.

- Supply Chain Complexity and Collaboration ● Circular supply chains Meaning ● Circular Supply Chains for SMBs: A regenerative system minimizing waste, maximizing resource use, and fostering sustainable growth. often involve more complex relationships and require greater collaboration with suppliers and partners. SMBs may need to build new partnerships, invest in supplier development, and establish robust communication and information sharing systems to manage circular supply chains effectively. Actively engaging with suppliers and fostering long-term collaborative relationships are crucial for building resilient circular supply chains.

- Market Acceptance and Customer Education ● Some circular business models, such as product-as-a-service or sharing economy models, may require shifts in customer behavior and market acceptance. SMBs need to invest in customer education, communicate the value proposition of circular offerings, and address potential concerns or perceptions. Clearly articulating the benefits of circular models to customers, such as cost savings, convenience, or environmental benefits, is essential for driving market adoption.

- Regulatory and Policy Landscape ● The regulatory and policy landscape for circular economy is still evolving in many regions. SMBs may face uncertainties or inconsistencies in regulations related to waste management, product standards, and circular economy incentives. Staying informed about policy developments, engaging with industry associations, and advocating for supportive policies are important for navigating the regulatory landscape and shaping a favorable environment for circular SMBs.

- Internal Capacity and Skill Gaps ● Implementing circular economy models Meaning ● A regenerative economic system minimizing waste and maximizing resource use for SMB sustainability and growth. requires new skills and knowledge within the SMB. This may involve training existing staff, hiring new talent with circular economy expertise, or seeking external consulting support. Investing in employee training and development, building internal circular economy expertise, and collaborating with external experts can address capacity and skill gaps.

By proactively addressing these intermediate-level challenges, SMBs can successfully implement more advanced circular economy models, unlocking greater environmental and economic benefits and positioning themselves as leaders in the transition to a circular economy.

| Circular Model Product Life Extension |

| Description Systematic approaches to prolong product lifespan (repair, upgrade, refurbishment). |

| SMB Applicability Highly applicable for durable goods SMBs (electronics, appliances, equipment). |

| Key Considerations for SMBs Requires design for durability and modularity, investment in repair infrastructure, customer education on repair services. |

| Circular Model Sharing Economy |

| Description Enabling shared access to products through rental, leasing, or platforms. |

| SMB Applicability Suitable for SMBs with underutilized assets (tools, vehicles, equipment), or those serving temporary needs. |

| Key Considerations for SMBs Requires digital platform development, logistics management, trust-building with users, insurance and liability considerations. |

| Circular Model Circular Supply Chain |

| Description Sourcing recycled/renewable materials, designing for closed-loop flows, sustainable supplier selection. |

| SMB Applicability Relevant for all SMBs, especially those with material-intensive products. |

| Key Considerations for SMBs Requires supplier collaboration, material traceability systems, investment in recycled material sourcing, product redesign for recyclability. |

| Circular Model Waste as Resource |

| Description Utilizing waste streams as inputs for new products or processes (industrial symbiosis). |

| SMB Applicability Applicable for SMBs generating significant waste streams, or those in proximity to other industries with complementary waste outputs. |

| Key Considerations for SMBs Requires waste stream characterization, partnership development, process innovation to utilize waste, regulatory compliance for waste-derived products. |

| Circular Model Product-Service Systems |

| Description Offering integrated product and service solutions, performance-based contracts. |

| SMB Applicability Suitable for SMBs offering complex equipment or systems, or those focused on delivering specific outcomes. |

| Key Considerations for SMBs Requires shift from product sales to service delivery, long-term customer contracts, remote monitoring and maintenance capabilities, performance measurement systems. |

Advanced

At the advanced echelon of Circular Economy SMB Models, the focus transcends operational improvements and business model adaptations. It delves into a profound re-evaluation of value creation, competitive advantage, and the very essence of sustainable business Meaning ● Sustainable Business for SMBs: Integrating environmental and social responsibility into core strategies for long-term viability and growth. within the SMB landscape. This advanced perspective recognizes that true circularity is not merely about optimizing material flows or adopting specific business models, but about fundamentally transforming the SMB’s role within a broader circular ecosystem. It necessitates a strategic vision that integrates circular principles into the core DNA of the SMB, driving innovation, resilience, and long-term value creation in a rapidly evolving global context.

Advanced Circular Economy SMB Models represent a profound re-evaluation of value creation, competitive advantage, and sustainable business, fundamentally transforming the SMB’s role in a circular ecosystem.

The advanced understanding of Circular Economy SMB Models for SMBs, derived from rigorous business research and data analysis, transcends simplistic definitions. It acknowledges the multifaceted nature of circularity, recognizing its diverse perspectives across industries, cultures, and economic contexts. Analyzing cross-sectorial influences reveals that circular economy principles are not industry-specific but universally applicable, albeit requiring tailored implementation strategies for each SMB sector.

Furthermore, multicultural business aspects highlight the importance of adapting circular models to diverse cultural norms and consumer behaviors across different markets. After extensive analysis, a refined, advanced definition emerges ● Circular Economy SMB Models Represent a Strategic Paradigm Shift for Small to Medium-Sized Businesses, Moving Beyond Linear ‘take-Make-Dispose’ Systems to Embrace Regenerative and Restorative Practices across Their Value Chain, Driven by Innovation, Collaboration, and a Commitment to Long-Term Sustainability, Ultimately Fostering Resilience, Competitive Differentiation, and New Value Creation Opportunities within a Complex and Interconnected Global Economy. This definition underscores the strategic imperative of circularity for SMBs in the 21st century, emphasizing its potential to drive not only environmental benefits but also significant economic and social value.

Strategic Implications of Advanced Circular Economy Models for SMBs

Adopting advanced circular economy models carries profound strategic implications for SMBs, shaping their competitive landscape, risk profile, and long-term growth trajectory. These implications extend beyond operational efficiencies and touch upon fundamental aspects of business strategy and value proposition:

Redefining Competitive Advantage

In an increasingly resource-constrained and environmentally conscious world, circularity becomes a potent source of competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. for SMBs. By embracing circular models, SMBs can differentiate themselves from competitors who adhere to linear ‘business-as-usual’ approaches. This differentiation can manifest in several forms:

- Enhanced Brand Reputation and Customer Loyalty ● Consumers are increasingly seeking out sustainable and ethical products and services. SMBs that demonstrably embrace circularity can build a strong brand reputation, attracting and retaining environmentally and socially conscious customers. Transparency in circular practices and clear communication of sustainability commitments are crucial for building trust and loyalty.

- Innovation and New Product/Service Development ● The transition to circularity necessitates innovation across all aspects of the business. SMBs that actively explore circular design, new materials, and innovative business models can develop unique products and services that meet evolving market demands and create new revenue streams. Circular innovation can lead to disruptive technologies and business models that redefine industry standards.

- Cost Leadership through Resource Efficiency ● Advanced circular models, particularly those focused on resource efficiency Meaning ● Resource Efficiency for SMBs: Optimizing resource use to maximize value, minimize waste, and ensure sustainable growth. and waste reduction, can drive significant cost savings for SMBs. Optimizing material usage, reducing waste disposal costs, and leveraging secondary resources can translate into lower operating expenses and improved profitability. Cost savings derived from circularity can be reinvested in further innovation and growth.

- Resilience and Supply Chain Security ● Circular supply chains, with their emphasis on local sourcing, recycled materials, and diversified resource streams, enhance SMB resilience to supply chain disruptions and resource price volatility. Reducing reliance on virgin resources and building closed-loop systems strengthens supply chain security and reduces vulnerability to external shocks. This resilience is particularly crucial in an era of increasing global uncertainty.

Navigating Systemic Change and Policy Influence

Advanced circular economy models require SMBs to engage with broader systemic changes and actively participate in shaping a supportive policy environment. This involves:

- Collaboration and Ecosystem Building ● True circularity is a collaborative endeavor that requires SMBs to work with suppliers, customers, competitors, and other stakeholders to build circular ecosystems. Participating in industry consortia, sharing knowledge and best practices, and forming strategic alliances are essential for driving systemic change and overcoming collective barriers to circularity. Ecosystem collaboration can unlock shared value and accelerate the transition to a circular economy.

- Policy Advocacy and Engagement ● SMBs have a crucial role to play in advocating for policies that support circular economy adoption. Engaging with policymakers, providing input on regulatory frameworks, and promoting circular economy incentives are essential for creating a level playing field and fostering a favorable business environment. Collective advocacy by SMB associations and industry groups can amplify their voice and influence policy decisions.

- Standardization and Certification ● The development and adoption of circular economy standards and certification schemes are crucial for ensuring transparency, credibility, and comparability of circular products and practices. SMBs can actively participate in the development of these standards and seek certification to demonstrate their commitment to circularity and build trust with customers and stakeholders. Standardization facilitates market recognition and reduces greenwashing risks.

- Embracing Digital Transformation Meaning ● Digital Transformation for SMBs: Strategic tech integration to boost efficiency, customer experience, and growth. and Data Sharing ● Digital technologies and data sharing platforms are essential enablers of advanced circular economy models. SMBs need to embrace digital transformation to improve supply chain traceability, optimize resource flows, and facilitate circular transactions. Sharing data within circular ecosystems, while addressing data privacy concerns, can unlock new opportunities for collaboration and innovation.

Long-Term Business Consequences and Success Insights

The long-term business consequences of embracing advanced circular economy models are overwhelmingly positive for SMBs that strategically commit to this transition. Success insights from pioneering circular SMBs reveal several key factors:

- Enhanced Long-Term Profitability and Value Creation ● While initial investments may be required, advanced circular models ultimately drive enhanced long-term profitability and value creation for SMBs. Resource efficiency, new revenue streams from circular services, and stronger brand reputation contribute to improved financial performance and increased business valuation. Circularity becomes a driver of sustainable and resilient profitability.

- Attracting and Retaining Talent ● Purpose-driven businesses that prioritize sustainability and circularity are increasingly attractive to top talent, particularly younger generations who are deeply concerned about environmental and social issues. Embracing circularity can enhance SMBs’ ability to attract and retain skilled employees, fostering innovation and organizational agility. A strong sustainability ethos becomes a competitive advantage in the talent market.

- Mitigating Future Risks and Ensuring Business Continuity ● In a world facing climate change, resource scarcity, and increasing regulatory pressures, circular economy models provide SMBs with a crucial risk mitigation strategy. By reducing resource dependence, diversifying supply chains, and adapting to evolving consumer preferences, circular SMBs are better positioned to navigate future uncertainties and ensure long-term business continuity. Circularity becomes a cornerstone of business resilience.

- Contributing to a Sustainable Future and Societal Impact ● Beyond direct business benefits, advanced circular economy models enable SMBs to contribute to a more sustainable future and generate positive societal impact. Reducing environmental footprint, conserving resources, and creating circular jobs contribute to broader societal goals and enhance SMBs’ social license to operate. Circularity becomes a vehicle for purpose-driven business and positive social change.

Advanced Automation and Implementation Strategies for Circular Economy SMB Models

Implementing advanced circular economy models requires sophisticated automation and implementation strategies that go beyond basic operational improvements. These strategies leverage cutting-edge technologies and innovative approaches to drive circularity at scale:

- AI-Powered Circular Design and Optimization ● Artificial intelligence (AI) and machine learning can be used to optimize product design for circularity, considering factors such as material selection, durability, recyclability, and disassembly. AI algorithms can analyze vast datasets to identify optimal design parameters and predict product lifecycles, enabling SMBs to create truly circular products. AI-powered design tools can accelerate innovation and improve the circularity performance of products.

- Robotics and Automation for Reverse Logistics and Material Recovery ● Robotics and automation are essential for streamlining reverse logistics processes and improving the efficiency of material recovery from end-of-life products. Automated sorting systems, robotic disassembly lines, and AI-powered quality control can significantly enhance the scale and effectiveness of circular material flows. Investing in advanced robotics and automation is crucial for closing material loops at scale.

- Digital Twins and Predictive Maintenance for Product Life Extension ● Digital twin technology, creating virtual replicas of physical products, can be used to monitor product performance in real-time, predict maintenance needs, and optimize product lifecycles. Predictive maintenance enabled by digital twins can extend product lifespan, reduce downtime, and improve resource utilization. Digital twins facilitate proactive product management and enhance the effectiveness of product life extension models.

- Blockchain-Enabled Circular Supply Chain Ecosystems ● Blockchain technology can create transparent and secure circular supply chain ecosystems, enabling traceability of materials, verification of recycled content, and secure transactions between circular economy actors. Blockchain can build trust and transparency in circular supply chains, facilitating collaboration and information sharing. Blockchain-based platforms can accelerate the development of robust and verifiable circular ecosystems.

- Decentralized and Distributed Circular Manufacturing Networks ● Advanced circular economy models can leverage decentralized and distributed manufacturing networks, enabled by technologies like 3D printing and digital fabrication. Localized production, on-demand manufacturing, and distributed recycling facilities can reduce transportation costs, minimize waste, and enhance resilience. Distributed manufacturing networks can foster regional circular economies and reduce reliance on centralized production systems.

By embracing these advanced automation and implementation strategies, SMBs can unlock the full potential of circular economy models, driving transformative change and establishing themselves as leaders in the transition to a sustainable and circular future. The journey to advanced circularity is not merely an operational upgrade; it is a strategic evolution that redefines the very purpose and potential of SMBs in the 21st century.

| Strategic Area Competitive Advantage |

| Advanced Considerations Circularity as core differentiator, brand building, innovation driver, cost leadership through efficiency, supply chain resilience. |

| SMB Implementation Focus Develop unique circular value propositions, transparent sustainability communication, invest in circular R&D, optimize resource use across value chain, build resilient local supply networks. |

| Strategic Area Systemic Change & Policy |

| Advanced Considerations Ecosystem collaboration, policy advocacy, standardization engagement, digital transformation for data sharing. |

| SMB Implementation Focus Participate in industry circularity initiatives, engage with policymakers on circular economy policies, adopt relevant circular economy standards, invest in digital platforms for circular data management. |

| Strategic Area Long-Term Business Impact |

| Advanced Considerations Enhanced profitability, talent attraction, risk mitigation, positive societal contribution. |

| SMB Implementation Focus Track circularity metrics and ROI, communicate sustainability performance to stakeholders, develop circular economy talent programs, integrate circularity into risk management, measure and report societal impact of circular initiatives. |

| Strategic Area Automation & Implementation |

| Advanced Considerations AI-powered design, robotics for reverse logistics, digital twins for product life extension, blockchain for supply chain transparency, distributed manufacturing. |

| SMB Implementation Focus Explore AI design tools for circularity, invest in automated waste sorting and material recovery, implement digital twin technology for product monitoring, pilot blockchain for supply chain traceability, evaluate feasibility of distributed manufacturing. |