Fundamentals

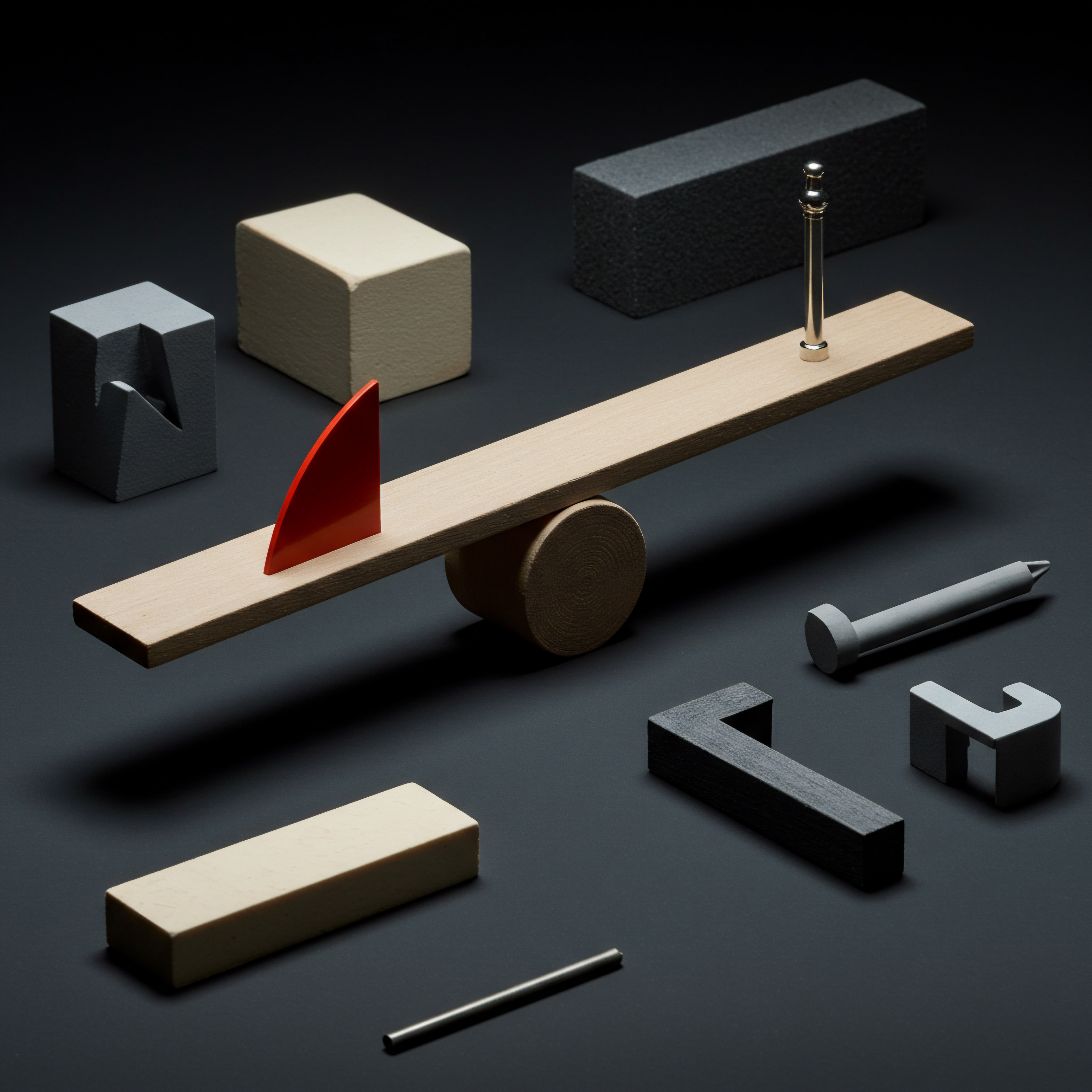

The Circular Digital Economy, at its most fundamental level, represents a paradigm shift in how businesses, particularly SMBs, operate and interact with resources and customers. Imagine a traditional linear economy as a ‘take-make-dispose’ model. Raw materials are extracted, products are made, used, and then discarded. This model is increasingly unsustainable, both environmentally and economically.

The Circular Digital Economy offers an alternative, aiming to minimize waste and maximize resource utilization by keeping materials and products in use for as long as possible. Digital technologies are the enablers of this circularity, providing the tools and platforms to track, manage, and optimize resource flows within this new economic framework.

The Circular Digital Economy for SMBs is about doing more with less, leveraging digital tools Meaning ● Digital tools, in the realm of Small and Medium-sized Businesses, represent software and online platforms designed to enhance operational efficiency, drive business growth, and automate key processes. to create sustainable and profitable business models.

For SMBs, often operating with limited resources and tighter margins than larger corporations, the concept of a circular economy Meaning ● A regenerative economic model for SMBs, maximizing resource use and minimizing waste for sustainable growth. might initially seem daunting or complex. However, the digital aspect is crucial in making circularity accessible and beneficial for smaller businesses. Digital tools and platforms can streamline processes, reduce operational costs, and unlock new revenue streams that were previously unattainable in a purely linear model. Think of it as using smart technology to make resource efficiency Meaning ● Resource Efficiency for SMBs: Optimizing resource use to maximize value, minimize waste, and ensure sustainable growth. not just environmentally responsible, but also economically advantageous for your SMB.

Understanding the Core Principles

To grasp the fundamentals of the Circular Digital Economy for SMBs, it’s essential to understand its core principles. These principles, when applied with digital technologies, can transform how SMBs operate and compete.

- Design for Durability and Longevity ● This principle emphasizes creating products and services that are built to last. For SMBs, this could mean investing in higher-quality materials, designing for modularity and repairability, or offering services that extend the lifespan of products. Digitally, this can be supported by using Product Lifecycle Management (PLM) software to track product components and lifecycles, or by providing online resources and tutorials for product maintenance and repair.

- Resource Efficiency and Waste Reduction ● Minimizing waste is central to circularity. For SMBs, this translates to optimizing resource consumption in operations, reducing packaging waste, and finding ways to reuse or repurpose materials. Digital tools like inventory management Meaning ● Inventory management, within the context of SMB operations, denotes the systematic approach to sourcing, storing, and selling inventory, both raw materials (if applicable) and finished goods. systems, waste tracking software, and energy monitoring platforms can help SMBs identify areas for improvement and track their progress in resource efficiency.

- Product as a Service (PaaS) ● Instead of selling products outright, SMBs can offer them as services. This shifts the focus from ownership to access, encouraging longer product lifespans and responsible resource use. For example, a small office equipment supplier could offer printer rentals instead of sales, maintaining and upgrading the printers as needed. Digital platforms are essential for managing PaaS models, handling subscriptions, usage tracking, and service delivery.

- Sharing and Collaborative Consumption ● The sharing economy, facilitated by digital platforms, allows SMBs to participate in collaborative consumption models. This could involve renting out underutilized assets, participating in shared logistics networks, or creating platforms for peer-to-peer product sharing within a local community. Digital platforms are the backbone of the sharing economy, connecting users and facilitating transactions.

- Remanufacturing and Recycling ● When products reach the end of their initial use, the Circular Digital Economy emphasizes remanufacturing, refurbishment, and high-quality recycling to recover valuable materials. SMBs can play a role by designing products for disassembly, offering take-back programs, or partnering with recycling facilities. Digital technologies, such as blockchain for material tracking and AI-powered sorting in recycling plants, enhance the efficiency and effectiveness of these processes.

Digital Enablers for SMB Circularity

The ‘digital’ in Circular Digital Economy is not just an add-on; it’s the engine that drives circularity at scale, especially for SMBs. Digital technologies provide the transparency, connectivity, and intelligence needed to manage complex circular systems effectively.

- Internet of Things (IoT) ● IoT devices, sensors, and connected products generate data that is crucial for tracking product usage, condition, and location. For SMBs, this data can be used to optimize product maintenance, predict failures, manage inventory more efficiently, and facilitate product take-back and reuse programs. Imagine a small coffee machine manufacturer using IoT sensors to monitor machine performance and schedule preventative maintenance for their PaaS customers, minimizing downtime and extending product life.

- Cloud Computing and Data Analytics ● Cloud Platforms provide affordable and scalable infrastructure for SMBs to store, process, and analyze the vast amounts of data generated in a circular economy. Data Analytics tools can extract valuable insights from this data, helping SMBs optimize resource flows, identify circular opportunities, and make data-driven decisions. For example, a small fashion retailer could use cloud-based analytics to track customer returns, identify product durability issues, and optimize their design and manufacturing processes.

- Blockchain Technology ● Blockchain offers transparency and traceability in supply chains, which is critical for building trust and verifying the circularity of products and materials. For SMBs, blockchain can be used to track the origin and journey of materials, verify ethical sourcing, and ensure the authenticity of recycled content. This is particularly valuable for SMBs in sectors like food, fashion, and electronics, where provenance and sustainability are increasingly important to consumers.

- Artificial Intelligence (AI) and Machine Learning (ML) ● AI and ML algorithms can automate complex tasks, optimize processes, and make predictions that enhance circularity. For SMBs, AI can be used for demand forecasting to reduce overproduction, optimize logistics for reverse supply chains, improve sorting efficiency in recycling facilities, and personalize product recommendations to encourage sustainable consumption. A small e-commerce business could use AI-powered tools to optimize packaging based on order size and delivery route, minimizing material use and shipping costs.

- Digital Platforms and Marketplaces ● Digital Platforms create ecosystems that connect businesses, consumers, and resources, facilitating circular transactions and collaborations. For SMBs, these platforms can provide access to new markets for used or refurbished products, connect them with suppliers of recycled materials, and enable participation in sharing economy models. Online marketplaces for used goods, platforms for renting equipment, and digital tools for managing product returns are all examples of digital platforms that support circularity.

Benefits of Circular Digital Economy for SMB Growth

Adopting a Circular Digital Economy approach is not just about environmental responsibility; it’s also a strategic move that can drive significant growth and resilience for SMBs. The benefits are multifaceted and can impact various aspects of an SMB’s operations and market position.

| Benefit Cost Savings |

| Description for SMBs Reduced material costs through resource efficiency, waste reduction, and reuse. Lower energy consumption through optimized processes. |

| Digital Implementation Examples Inventory management software, energy monitoring systems, waste tracking apps, digital twins for process optimization. |

| Benefit New Revenue Streams |

| Description for SMBs Product-as-a-Service models, resale and refurbishment of products, sale of by-products or waste materials, circular economy consulting services. |

| Digital Implementation Examples E-commerce platforms for refurbished goods, subscription management software, online marketplaces for waste materials, digital marketing for new service offerings. |

| Benefit Enhanced Customer Loyalty |

| Description for SMBs Attracting and retaining customers who value sustainability and ethical business practices. Building stronger customer relationships through PaaS models and circular services. |

| Digital Implementation Examples Customer relationship management (CRM) systems to track customer preferences, loyalty programs for sustainable choices, digital communication channels to highlight circular initiatives. |

| Benefit Improved Brand Reputation |

| Description for SMBs Positioning the SMB as a leader in sustainability and innovation. Differentiating from competitors by offering circular products and services. |

| Digital Implementation Examples Social media marketing to showcase circular practices, sustainability reporting using digital tools, online certifications and badges for circularity. |

| Benefit Increased Resilience |

| Description for SMBs Reduced dependence on virgin resources and volatile supply chains. Diversification of revenue streams, making the business more adaptable to economic changes. |

| Digital Implementation Examples Supply chain management software for diversified sourcing, risk management platforms to assess supply chain vulnerabilities, digital tools for scenario planning and business continuity. |

| Benefit Innovation and Competitive Advantage |

| Description for SMBs Driving innovation in product design, service delivery, and business models. Creating a unique value proposition that attracts customers and investors. |

| Digital Implementation Examples Digital collaboration platforms for innovation and design thinking, data analytics to identify new circular opportunities, digital prototyping and simulation tools. |

In essence, the fundamentals of the Circular Digital Economy for SMBs are about embracing a smarter, more sustainable way of doing business. By leveraging digital technologies and adopting circular principles, SMBs can unlock significant economic and environmental benefits, paving the way for long-term growth and success in an increasingly resource-constrained world.

Intermediate

Building upon the foundational understanding of the Circular Digital Economy, the intermediate level delves into more nuanced aspects, particularly focusing on the strategic implementation and operational complexities for SMBs. While the fundamentals highlight the ‘what’ and ‘why’, the intermediate level addresses the ‘how’ ● how SMBs can practically integrate circular digital strategies into their existing business models and operations. This involves navigating challenges, leveraging specific digital tools, and adopting tailored approaches that align with their unique size, resources, and market position.

For SMBs, the intermediate stage of Circular Digital Economy adoption is about strategic implementation ● moving from understanding the concepts to actively integrating circular practices into core business operations.

Circular Business Model Innovation for SMBs

Moving beyond linear models requires SMBs to innovate their business models. The Circular Digital Economy offers a range of innovative models that SMBs can adapt and implement, often leveraging digital platforms and technologies to facilitate these transitions.

Product-As-A-Service (PaaS) Deep Dive

Product-As-A-Service (PaaS) is a transformative business model where SMBs offer the functionality of a product rather than the product itself. This shift has profound implications for resource consumption and customer relationships. For SMBs, PaaS can unlock new revenue streams, foster stronger customer loyalty, and drive product innovation focused on durability and performance.

- Benefits of PaaS for SMBs ●

- Recurring Revenue ● PaaS models generate predictable, recurring revenue streams through subscriptions or usage-based fees, providing financial stability for SMBs.

- Customer Retention ● Long-term service agreements foster stronger customer relationships Meaning ● Customer Relationships, within the framework of SMB expansion, automation processes, and strategic execution, defines the methodologies and technologies SMBs use to manage and analyze customer interactions throughout the customer lifecycle. and increase customer lifetime value.

- Resource Efficiency ● Incentivizes SMBs to design durable, high-quality products that last longer and require less maintenance, reducing resource consumption over time.

- Data-Driven Product Improvement ● Continuous interaction with products in use provides valuable data on performance, usage patterns, and potential improvements, driving product innovation.

- Digital Technologies Enabling PaaS ●

- IoT Sensors and Connectivity ● Track product usage, performance, and location, enabling remote monitoring, predictive maintenance, and usage-based billing.

- Cloud Platforms ● Manage subscriptions, billing, customer data, and service delivery, providing scalable infrastructure for PaaS operations.

- Mobile Apps and Customer Portals ● Provide customers with access to service management, usage data, support, and communication channels.

- Data Analytics and AI ● Analyze usage data to optimize service delivery, predict maintenance needs, personalize customer experiences, and identify product improvement opportunities.

- SMB PaaS Implementation Strategies ●

- Start with a Pilot Project ● Test PaaS model with a specific product or service offering before full-scale implementation to minimize risk and refine the approach.

- Focus on Value-Added Services ● Go beyond basic product functionality and offer value-added services like maintenance, upgrades, training, and support to enhance customer value proposition.

- Develop Clear Service Level Agreements (SLAs) ● Define clear terms of service, responsibilities, and performance metrics to manage customer expectations and ensure service quality.

- Invest in Digital Infrastructure ● Select and implement appropriate digital technologies to support PaaS operations, focusing on scalability, security, and integration with existing systems.

Circular Supply Chains and Reverse Logistics

Linear supply chains are designed for a one-way flow of materials from raw material extraction to end-of-life disposal. Circular supply chains, in contrast, aim to close the loop by recovering and reusing materials and products. For SMBs, building circular supply chains Meaning ● Circular Supply Chains for SMBs: A regenerative system minimizing waste, maximizing resource use, and fostering sustainable growth. involves rethinking sourcing, production, distribution, and end-of-life management, often requiring collaboration with partners and leveraging digital technologies for transparency and efficiency.

- Key Elements of Circular Supply Chains for SMBs ●

- Sustainable Sourcing ● Prioritizing recycled, renewable, and ethically sourced materials. Digital platforms can help SMBs identify and connect with sustainable suppliers, verify material certifications, and track material provenance using blockchain.

- Design for Circularity ● Designing products for durability, disassembly, and recyclability. Product Lifecycle Management (PLM) software and digital design tools can facilitate circular design principles.

- Efficient Production and Manufacturing ● Optimizing resource utilization, minimizing waste generation, and using cleaner production technologies. Digital twins and process simulation tools can help SMBs optimize manufacturing processes for resource efficiency.

- Reverse Logistics and Product Take-Back ● Establishing systems for collecting used products for reuse, remanufacturing, or recycling. Digital platforms and logistics software can streamline reverse logistics operations, track product returns, and manage inventory of returned goods.

- Collaboration and Partnerships ● Working with suppliers, distributors, recyclers, and other stakeholders to build a circular ecosystem. Digital collaboration platforms can facilitate communication, data sharing, and coordination among supply chain partners.

- Challenges in Implementing Circular Supply Chains for SMBs ●

- Complexity and Cost ● Circular supply chains can be more complex and initially more costly to set up than linear supply chains. SMBs need to carefully assess the costs and benefits and prioritize areas for circularity based on their resources and capabilities.

- Lack of Infrastructure ● Reverse logistics infrastructure and recycling facilities may be limited in certain regions. SMBs may need to collaborate with industry partners or advocate for improved infrastructure development.

- Data and Transparency ● Tracking materials and products throughout the circular supply chain requires robust data management and transparency. SMBs need to invest in digital systems for data collection, analysis, and sharing.

- Consumer Behavior and Acceptance ● Consumer acceptance of reused, remanufactured, or recycled products is crucial for the success of circular supply chains. SMBs need to educate consumers about the benefits of circular products and build trust through transparency and quality assurance.

- Digital Tools for Circular Supply Chain Management ●

- Supply Chain Management (SCM) Software ● Manage inventory, track orders, optimize logistics, and improve communication with suppliers and distributors. Cloud-based SCM solutions are accessible and affordable for SMBs.

- Blockchain for Supply Chain Transparency ● Track material provenance, verify certifications, and ensure ethical sourcing. Blockchain can enhance trust and transparency in circular supply chains, particularly for materials like recycled plastics or ethically sourced minerals.

- Reverse Logistics Software ● Manage product returns, track returned inventory, optimize reverse logistics routes, and coordinate with recycling partners. Specialized software solutions are available to streamline reverse logistics operations.

- Data Analytics for Supply Chain Optimization ● Analyze supply chain data to identify inefficiencies, optimize resource flows, predict demand, and improve decision-making. Data analytics Meaning ● Data Analytics, in the realm of SMB growth, represents the strategic practice of examining raw business information to discover trends, patterns, and valuable insights. tools can help SMBs optimize their circular supply chain performance.

Automation and Implementation Strategies for SMBs

Implementing Circular Digital Economy strategies requires a phased approach, leveraging automation to streamline processes and maximize efficiency. For SMBs, automation is not just about reducing labor costs; it’s about enabling scalability, improving accuracy, and freeing up resources for strategic initiatives.

Phased Implementation Approach

A step-by-step, phased approach is crucial for SMBs to successfully adopt Circular Digital Economy principles. Trying to implement everything at once can be overwhelming and resource-intensive. A phased approach allows SMBs to prioritize initiatives, learn from each phase, and build momentum gradually.

- Phase 1 ● Assessment and Planning ●

- Circular Opportunity Assessment ● Identify areas within the SMB’s operations where circular principles can be applied. This could involve analyzing material flows, waste streams, product lifecycles, and customer needs. Tools like material flow analysis and lifecycle assessment can be helpful.

- Digital Readiness Assessment ● Evaluate the SMB’s existing digital infrastructure, skills, and capabilities. Identify gaps and areas for improvement in digital technologies and data management.

- Strategic Planning ● Develop a circular digital strategy aligned with the SMB’s overall business goals. Define specific, measurable, achievable, relevant, and time-bound (SMART) objectives for circularity and digitalization.

- Phase 2 ● Pilot Projects and Quick Wins ●

- Implement Pilot Projects ● Start with small-scale pilot projects to test circular digital initiatives in a controlled environment. This could involve implementing a digital waste tracking system, launching a PaaS pilot for a specific product, or testing a reverse logistics program in a limited geographic area.

- Focus on Quick Wins ● Prioritize initiatives that can deliver early and visible results. Quick wins build momentum, demonstrate the value of circularity and digitalization, and generate buy-in from stakeholders.

- Data Collection and Analysis ● Collect data from pilot projects to measure performance, identify challenges, and refine implementation strategies. Use data analytics to track key metrics and assess the impact of circular initiatives.

- Phase 3 ● Scaling and Integration ●

- Scale Successful Pilots ● Expand successful pilot projects to broader operations and product lines. Replicate proven approaches and adapt them to different contexts within the SMB.

- Integrate Circularity into Core Operations ● Embed circular principles into core business processes, such as product design, manufacturing, marketing, and customer service. Make circularity a central part of the SMB’s business model.

- Automate Processes ● Leverage automation technologies to streamline circular processes, improve efficiency, and reduce manual effort. Implement digital systems for inventory management, supply chain tracking, reverse logistics, and customer relationship management.

- Phase 4 ● Continuous Improvement Meaning ● Ongoing, incremental improvements focused on agility and value for SMB success. and Innovation ●

- Monitor and Measure Performance ● Continuously monitor and measure the performance of circular digital initiatives using key performance indicators Meaning ● Key Performance Indicators (KPIs) represent measurable values that demonstrate how effectively a small or medium-sized business (SMB) is achieving key business objectives. (KPIs). Track progress towards circularity goals and identify areas for improvement.

- Embrace Continuous Improvement ● Adopt a culture of continuous improvement, regularly reviewing and refining circular strategies and processes based on data and feedback. Use data analytics to identify opportunities for optimization and innovation.

- Foster Innovation ● Encourage innovation in circular product design, service delivery, and business models. Explore new digital technologies and circular economy trends to stay ahead of the curve and maintain a competitive advantage.

Leveraging Automation for Circular Processes

Automation is a critical enabler for scaling circular processes and maximizing efficiency for SMBs. Digital technologies provide a wide range of automation tools that can be applied across various aspects of the Circular Digital Economy.

| Circular Process Inventory Management |

| Automation Technologies IoT sensors, RFID tags, inventory management software, AI-powered demand forecasting |

| SMB Benefits Reduced inventory holding costs, minimized waste from obsolete inventory, optimized stock levels, improved order fulfillment |

| Circular Process Supply Chain Tracking |

| Automation Technologies Blockchain, IoT sensors, GPS tracking, supply chain management software |

| SMB Benefits Enhanced supply chain transparency, improved traceability of materials, reduced risk of counterfeit products, optimized logistics routes |

| Circular Process Reverse Logistics |

| Automation Technologies Reverse logistics software, mobile apps for product returns, automated sorting systems, AI-powered route optimization |

| SMB Benefits Streamlined product returns process, reduced reverse logistics costs, improved efficiency of product collection and processing, enhanced customer experience |

| Circular Process Waste Management |

| Automation Technologies Smart waste bins, waste tracking software, AI-powered sorting in recycling facilities, automated waste collection systems |

| SMB Benefits Improved waste segregation and recycling rates, reduced waste disposal costs, optimized waste collection routes, enhanced resource recovery |

| Circular Process Customer Relationship Management (CRM) |

| Automation Technologies CRM software, chatbots, automated email marketing, personalized customer portals |

| SMB Benefits Improved customer engagement, personalized customer service, streamlined communication, enhanced customer loyalty, efficient management of PaaS subscriptions |

By strategically implementing these intermediate-level strategies and leveraging digital automation, SMBs can move beyond basic circularity and create truly resilient, sustainable, and competitive businesses within the Circular Digital Economy. The key is to approach implementation systematically, prioritize initiatives based on business value, and continuously adapt and innovate to stay ahead in this evolving economic landscape.

Advanced

The Circular Digital Economy, viewed through an advanced lens, transcends a mere operational shift for SMBs; it represents a fundamental restructuring of economic paradigms, driven by the convergence of circular economy principles and advanced digital technologies. This perspective necessitates a rigorous examination of its theoretical underpinnings, its multifaceted implications across diverse business sectors, and its potential to reshape the very fabric of SMB operations and their role within global value chains. The advanced exploration demands a critical analysis of existing research, data-driven insights, and a nuanced understanding of the long-term, often complex, consequences for SMBs navigating this transformative economic landscape.

Scholarly, the Circular Digital Economy is not just a business trend, but a complex socio-technical system requiring deep interdisciplinary analysis to understand its full potential and challenges for SMBs.

Redefining the Circular Digital Economy ● An Advanced Perspective

From an advanced standpoint, the Circular Digital Economy can be rigorously defined as a Socio-Technical System that leverages digital technologies to facilitate and accelerate the transition from linear ‘take-make-dispose’ economic models to circular systems characterized by closed-loop resource flows, extended product lifecycles, and minimized environmental impact. This definition emphasizes the interconnectedness of social, economic, and technological dimensions, recognizing that the successful implementation of a Circular Digital Economy requires not only technological innovation but also societal shifts in consumption patterns, business practices, and regulatory frameworks.

Drawing upon reputable business research and scholarly articles, we can further refine this definition by considering diverse perspectives and cross-sectoral influences. The Circular Digital Economy is not a monolithic concept; its manifestation and implications vary significantly across different industries, geographical contexts, and organizational scales. For SMBs, operating within specific local and regional ecosystems, the nuances of this definition become particularly salient. For instance, a small manufacturing SMB in a developing economy might face vastly different challenges and opportunities in adopting circular digital practices compared to a tech-startup SMB in a developed urban center.

Analyzing its diverse perspectives reveals that the Circular Digital Economy is influenced by multiple advanced disciplines, including:

- Industrial Ecology ● Provides the theoretical framework for understanding material and energy flows within industrial systems and ecosystems. Industrial Ecology principles inform the design of circular systems aimed at minimizing resource depletion and pollution. For SMBs, this translates to adopting lifecycle thinking and optimizing resource utilization across their value chains.

- Information Systems ● Focuses on the role of digital technologies in enabling information sharing, data analytics, and process automation within circular systems. Information Systems Research explores how technologies like IoT, blockchain, and AI can facilitate circular business models Meaning ● Circular Business Models redefine SMB operations towards resource efficiency and regeneration for sustainable growth. and supply chains for SMBs.

- Sustainability Science ● Examines the complex interactions between human and natural systems, seeking solutions to global sustainability challenges. Sustainability Science provides a broader context for understanding the environmental and social benefits of the Circular Digital Economy and its contribution to sustainable development goals relevant to SMBs.

- Business Strategy and Innovation ● Analyzes how businesses can create competitive advantage Meaning ● SMB Competitive Advantage: Ecosystem-embedded, hyper-personalized value, sustained by strategic automation, ensuring resilience & impact. and drive innovation through circular business models and digital transformation. Strategic Management Research explores how SMBs can leverage the Circular Digital Economy to develop new value propositions, access new markets, and enhance their resilience.

- Economics ● Investigates the economic implications of circularity, including resource efficiency, economic growth, and job creation. Economic Research examines the macroeconomic and microeconomic impacts of the Circular Digital Economy, providing insights into policy frameworks and business incentives that can support SMB adoption.

Considering multi-cultural business aspects, the interpretation and implementation of the Circular Digital Economy are also shaped by cultural values, societal norms, and regulatory environments across different regions. For example, in some cultures, repair and reuse are deeply ingrained practices, while in others, consumerism and disposability are more prevalent. SMBs operating in international markets need to be sensitive to these cultural nuances and adapt their circular digital strategies accordingly. Furthermore, regulatory frameworks related to waste management, product stewardship, and data privacy Meaning ● Data privacy for SMBs is the responsible handling of personal data to build trust and enable sustainable business growth. vary significantly across countries, impacting the feasibility and implementation of circular digital initiatives for global SMBs.

Analyzing cross-sectorial business influences reveals that the Circular Digital Economy is not confined to specific industries; it has the potential to transform virtually all sectors of the economy. However, the specific challenges and opportunities vary significantly across sectors. For instance:

- Manufacturing ● Focuses on circular product design, remanufacturing, and closed-loop material flows. Digital technologies enable product lifecycle management, predictive maintenance, and efficient reverse logistics for manufacturing SMBs.

- Retail and Consumer Goods ● Emphasizes product-as-a-service models, sharing economy platforms, and sustainable consumption patterns. Digital platforms facilitate product rentals, resale marketplaces, and personalized recommendations for sustainable products for retail SMBs.

- Agriculture and Food ● Focuses on reducing food waste, optimizing resource utilization in agriculture, and developing circular food systems. Digital technologies enable precision agriculture, supply chain traceability, and food waste management solutions for SMBs in the food sector.

- Construction and Infrastructure ● Emphasizes circular building materials, design for deconstruction, and waste reduction in construction. Digital tools facilitate building information modeling (BIM), material passports, and waste tracking for construction SMBs.

- Services ● Focuses on optimizing resource utilization in service delivery, promoting dematerialization, and developing circular service models. Digital platforms enable remote service delivery, resource sharing, and data-driven service optimization for service-based SMBs.

For the purpose of in-depth business analysis, we will focus on the Manufacturing Sector and its specific challenges and opportunities within the Circular Digital Economy. Manufacturing SMBs are crucial drivers of economic growth and employment, but they also contribute significantly to resource consumption and environmental pollution. The transition to a Circular Digital Economy in manufacturing offers immense potential for SMBs to enhance their competitiveness, reduce their environmental footprint, and contribute to a more sustainable industrial system.

In-Depth Business Analysis ● Circular Digital Economy in Manufacturing SMBs

Manufacturing SMBs face unique challenges and opportunities in adopting Circular Digital Economy principles. They often operate with limited resources, tighter margins, and less access to advanced technologies compared to larger corporations. However, their agility, flexibility, and close customer relationships can also be significant advantages in implementing circular innovations. A deep business analysis requires examining the specific barriers, enablers, and strategic pathways for manufacturing SMBs to thrive in a Circular Digital Economy.

Challenges for Manufacturing SMBs in Circular Digital Transition

Despite the potential benefits, manufacturing SMBs encounter several significant challenges in transitioning to a Circular Digital Economy:

- Financial Constraints and Investment Barriers ● Implementing circular digital solutions often requires upfront investments in new technologies, infrastructure, and skills. SMBs may face financial constraints in accessing capital for these investments, particularly in the initial stages of transition. The perceived risk and uncertain return on investment can also deter SMBs from adopting circular digital practices.

- Lack of Technical Expertise and Skills Gap ● The Circular Digital Economy requires new skills and expertise in areas such as digital technologies, data analytics, circular design, and reverse logistics. Manufacturing SMBs may lack in-house expertise in these areas and face challenges in attracting and retaining talent with the necessary skills. The skills gap can hinder the effective implementation and management of circular digital initiatives.

- Supply Chain Complexity and Collaboration Challenges ● Circular supply chains are inherently more complex than linear supply chains, requiring closer collaboration and coordination among multiple stakeholders. Manufacturing SMBs may struggle to manage the complexity of circular supply chains, particularly in terms of sourcing recycled materials, managing reverse logistics, and coordinating with recycling partners. Lack of trust and information sharing among supply chain partners can also be a barrier.

- Regulatory Uncertainty and Policy Gaps ● The regulatory landscape for the Circular Digital Economy is still evolving, and SMBs may face uncertainty regarding environmental regulations, product standards, and data privacy requirements. Policy gaps and inconsistent regulations across different regions can create barriers to cross-border circular business models and investments. Lack of clear policy signals and incentives can also slow down the adoption of circular practices.

- Market Demand and Consumer Acceptance ● While consumer awareness of sustainability is growing, market demand for circular products and services may still be limited in certain sectors or regions. Manufacturing SMBs may face challenges in creating market demand for their circular offerings and overcoming consumer perceptions about the quality or performance of recycled or remanufactured products. Lack of consumer education and awareness can hinder market uptake.

Opportunities for Manufacturing SMBs in Circular Digital Economy

Despite these challenges, the Circular Digital Economy presents significant opportunities for manufacturing SMBs to enhance their competitiveness, drive innovation, and achieve sustainable growth:

- Cost Reduction and Resource Efficiency Gains ● Circular digital practices can lead to significant cost reductions for manufacturing SMBs through resource efficiency gains, waste minimization, and reduced reliance on virgin materials. Digital technologies enable optimized resource utilization, predictive maintenance, and efficient waste management, leading to lower operational costs and improved profitability.

- New Revenue Streams and Business Model Innovation ● The Circular Digital Economy opens up new revenue streams for manufacturing SMBs through product-as-a-service models, remanufacturing and refurbishment services, and the sale of by-products or waste materials. Digital platforms facilitate the development of innovative circular business models and the creation of new value propositions for customers.

- Enhanced Brand Reputation Meaning ● Brand reputation, for a Small or Medium-sized Business (SMB), represents the aggregate perception stakeholders hold regarding its reliability, quality, and values. and Customer Loyalty ● Adopting circular digital practices can enhance the brand reputation of manufacturing SMBs and attract environmentally conscious customers. Consumers are increasingly demanding sustainable products and services, and SMBs that demonstrate a commitment to circularity can gain a competitive advantage and build stronger customer loyalty. Transparency and traceability enabled by digital technologies can further enhance brand trust.

- Innovation and Product Differentiation ● The Circular Digital Economy drives innovation in product design, manufacturing processes, and service delivery. Manufacturing SMBs that embrace circular principles can differentiate themselves from competitors by offering innovative, sustainable products and services that meet evolving customer needs and market demands. Digital technologies enable rapid prototyping, data-driven design optimization, and personalized product offerings.

- Increased Resilience and Supply Chain Security ● Circular supply chains reduce reliance on virgin resources and volatile global supply chains, enhancing the resilience of manufacturing SMBs to external shocks and resource scarcity. Diversifying material sources, utilizing recycled materials, and establishing local circular ecosystems can improve supply chain security and reduce vulnerability to disruptions. Digital technologies enable supply chain visibility and risk management.

Strategic Pathways for SMB Success in Circular Digital Economy

To capitalize on these opportunities and overcome the challenges, manufacturing SMBs need to adopt strategic pathways tailored to their specific context and capabilities:

- Develop a Circular Digital Strategy ● SMBs should develop a clear and comprehensive circular digital strategy aligned with their overall business goals. This strategy should define specific circular objectives, identify priority areas for action, outline implementation plans, and establish key performance indicators (KPIs) to track progress. The strategy should be data-driven and iterative, adapting to evolving market conditions and technological advancements.

- Invest in Digital Technologies and Skills Development ● SMBs need to invest strategically in digital technologies that support their circular initiatives. This may include adopting cloud-based platforms, IoT sensors, data analytics tools, and blockchain solutions. Simultaneously, SMBs should invest in skills development and training programs to build in-house expertise in digital technologies, circular design, and data analysis. Partnerships with technology providers and educational institutions can facilitate access to expertise and training resources.

- Foster Collaboration and Build Circular Ecosystems ● SMBs should actively seek collaboration with suppliers, customers, competitors, research institutions, and government agencies to build circular ecosystems. Collaboration can facilitate resource sharing, knowledge exchange, and joint innovation projects. Digital platforms can play a crucial role in connecting stakeholders and enabling collaboration across circular value chains. Industry associations and regional clusters can also provide valuable platforms for collaboration.

- Advocate for Supportive Policies and Regulations ● SMBs should actively engage with policymakers and advocate for supportive policies and regulations that promote the Circular Digital Economy. This includes advocating for incentives for circular investments, streamlined environmental permitting processes, clear product standards for recycled materials, and data privacy regulations that facilitate data sharing within circular ecosystems. Collective action through industry associations can amplify the voice of SMBs in policy discussions.

- Embrace a Culture of Innovation Meaning ● A pragmatic, systematic capability to implement impactful changes, enhancing SMB value within resource constraints. and Experimentation ● SMBs need to foster a culture of innovation and experimentation to drive continuous improvement in their circular digital practices. This involves encouraging employees to generate new ideas, piloting innovative solutions, and learning from both successes and failures. Data-driven decision-making and agile methodologies can support a culture of experimentation and continuous improvement. Open innovation approaches, involving external partners in the innovation process, can also accelerate circular innovation.

By embracing these strategic pathways, manufacturing SMBs can not only navigate the challenges of the Circular Digital Economy but also unlock its transformative potential to achieve sustainable growth, enhance their competitiveness, and contribute to a more resilient and resource-efficient industrial future. The advanced perspective underscores that the Circular Digital Economy is not merely a trend but a fundamental shift requiring strategic foresight, technological adaptation, and collaborative action for SMBs to thrive in the long term.

Long-Term Business Consequences and Success Insights for SMBs

The long-term business consequences of embracing the Circular Digital Economy for SMBs are profound and far-reaching. Those SMBs that proactively adapt and integrate circular digital principles into their core strategies are likely to experience significant advantages in terms of resilience, competitiveness, and long-term sustainability. Conversely, SMBs that fail to adapt risk being left behind in an increasingly resource-constrained and environmentally conscious global economy.

Long-Term Consequences ●

- Enhanced Long-Term Resilience ● SMBs operating within circular digital models will be more resilient to resource price volatility, supply chain disruptions, and changing consumer preferences. Reduced dependence on virgin resources and diversified revenue streams will provide greater stability and adaptability in the face of economic and environmental uncertainties.

- Sustainable Competitive Advantage ● Circular digital practices will become increasingly important sources of competitive advantage. SMBs that are early adopters and innovators in circularity will be able to differentiate themselves in the market, attract environmentally conscious customers, and build stronger brand loyalty. Sustainability will become a core element of competitive strategy.

- Attraction of Talent and Investment ● SMBs with strong sustainability credentials and circular business models will be more attractive to talent and investors. Millennial and Gen Z employees are increasingly seeking purpose-driven organizations, and investors are increasingly prioritizing ESG (Environmental, Social, and Governance) factors in their investment decisions. Circularity will become a key factor in attracting and retaining both human and financial capital.

- Contribution to Sustainable Development Goals (SDGs) ● By embracing the Circular Digital Economy, SMBs can make a significant contribution to achieving the United Nations Sustainable Development Goals (SDGs), particularly those related to responsible consumption and production, climate action, and resource efficiency. This contribution can enhance their societal legitimacy and strengthen their long-term license to operate.

- Transformation of Industrial Ecosystems ● Widespread adoption of circular digital practices by SMBs will contribute to the transformation of entire industrial ecosystems towards greater circularity and sustainability. This systemic shift will create new opportunities for collaboration, innovation, and value creation across value chains and sectors, fostering a more resilient and regenerative economy.

Success Insights for SMBs ●

- Embrace a Long-Term Vision ● Circular Digital Economy transformation is a long-term journey, not a quick fix. SMBs need to adopt a long-term vision and commit to a gradual and iterative process of change. Patience, persistence, and a willingness to adapt are crucial for success.

- Focus on Value Creation, Not Just Cost Reduction ● While cost reduction is a benefit of circularity, SMBs should focus on creating new value propositions for customers and stakeholders. Circular business models can unlock new revenue streams, enhance customer experiences, and create positive social and environmental impact. Value creation should be the primary driver of circular innovation.

- Data-Driven Decision Making is Essential ● Data is the lifeblood of the Circular Digital Economy. SMBs need to invest in data collection, analysis, and utilization to inform their circular strategies and optimize their operations. Data-driven decision-making is crucial for identifying opportunities, measuring performance, and driving continuous improvement.

- Collaboration is Key to Scaling Impact ● No SMB can achieve circularity in isolation. Collaboration with suppliers, customers, competitors, and other stakeholders is essential for building circular ecosystems and scaling impact. Open communication, trust-building, and shared value creation are key to successful collaboration.

- Sustainability is a Journey of Continuous Improvement ● Sustainability is not a destination but a journey of continuous improvement. SMBs should embrace a mindset of continuous learning, experimentation, and adaptation. Regularly reviewing and refining circular strategies and processes is essential to stay ahead of the curve and maximize long-term impact.

In conclusion, the advanced analysis of the Circular Digital Economy for manufacturing SMBs reveals a complex yet profoundly transformative landscape. By understanding the challenges, seizing the opportunities, and adopting strategic pathways grounded in innovation, collaboration, and a long-term vision, SMBs can not only survive but thrive in this new economic era, contributing to a more sustainable and prosperous future for all.